Rapid optimization method of electrolyte formula for lithium-ion batteries

A lithium-ion battery and optimization method technology, applied in secondary batteries, electrochemical generators, secondary battery repair/maintenance, etc., can solve the problems of time-consuming and labor-intensive, and the inability to know the decomposition speed of additives, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0024] A method for rapidly optimizing the electrolyte formula of a lithium-ion battery, comprising the steps of:

[0025] Prepare a lithium-ion battery electrolyte E1, wherein the lithium salt LiPF6 accounts for 13%, the solvent EC:EMC=3:7 accounts for 83%, the additive A is TMSB and accounts for 2%, and the additive B is VC and accounts for 2%.

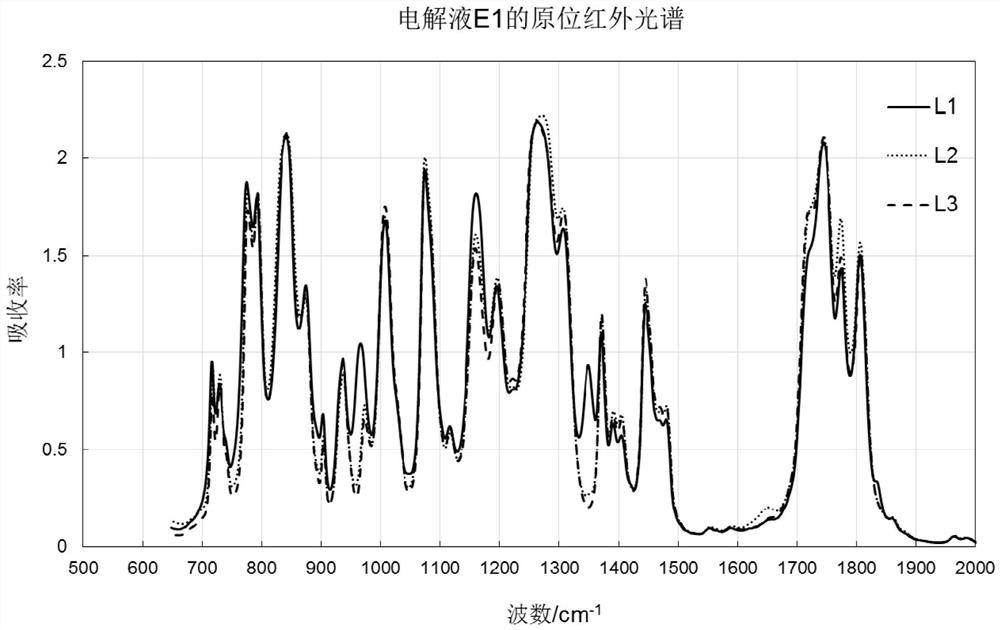

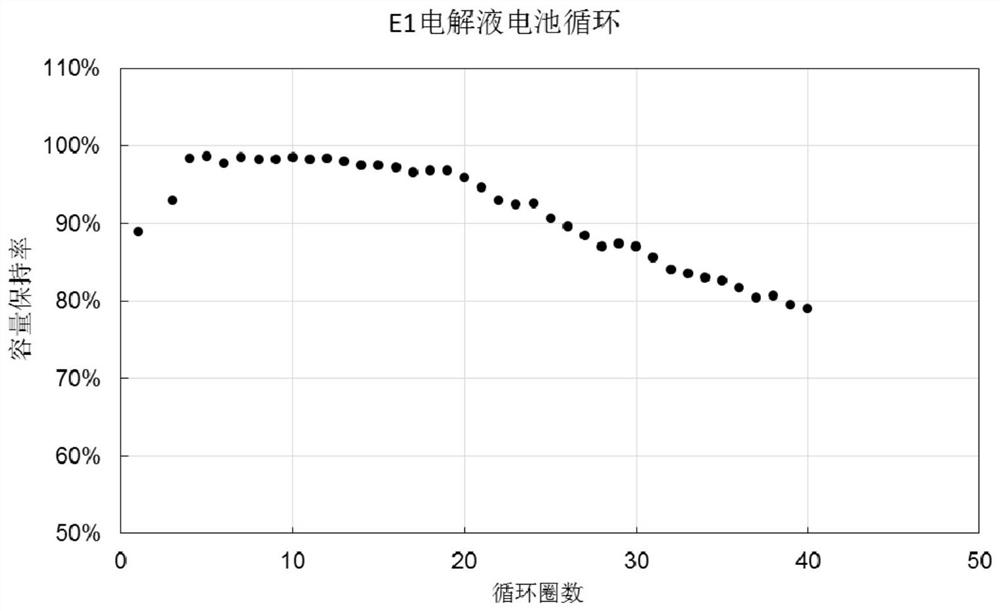

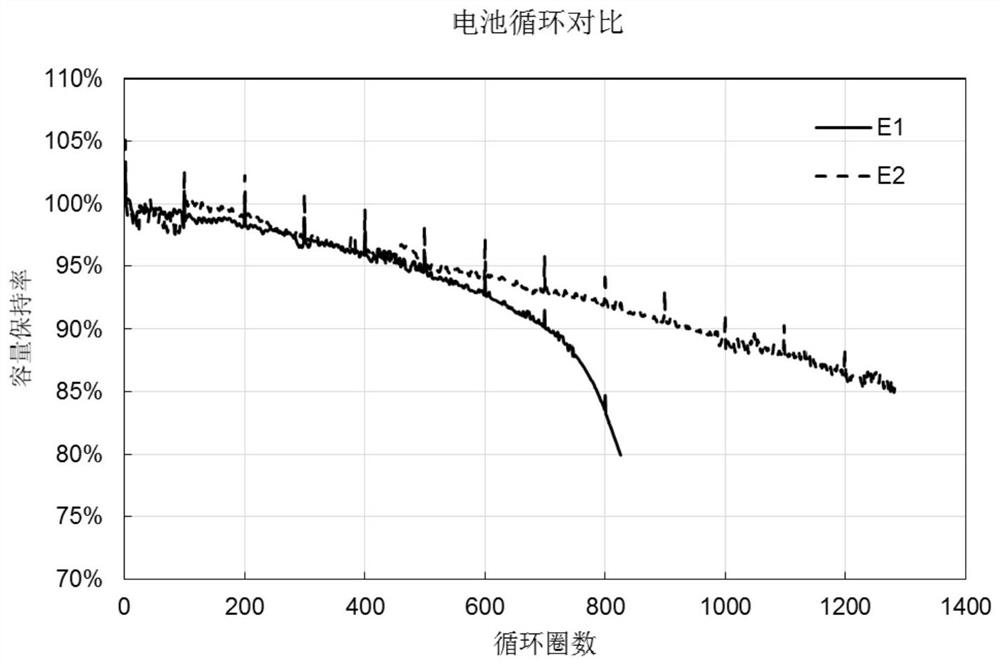

[0026] Assemble the electrolyte E1, punched positive electrode sheet, negative electrode sheet, separator and in-situ infrared sample cell into a simple battery Figure 4 show. Test the infrared spectrum absorption peak of electrolyte E1, such as figure 1 Shown in L1. During the experiment, the infrared rays emitted by the light source 5 enter the in-situ infrared sample ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com