Biomacromolecule medicine granulator

A biomacromolecule and granulator technology, which is applied in the direction of mixers, mixers with rotating stirring devices, and devices that make drugs into special physical or ingestible forms, and can solve the problem of drug powder lifting and accumulation of drug powder. , Affecting the quality of drug granulation and other issues, to achieve the effect of ensuring the quality of granulation and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

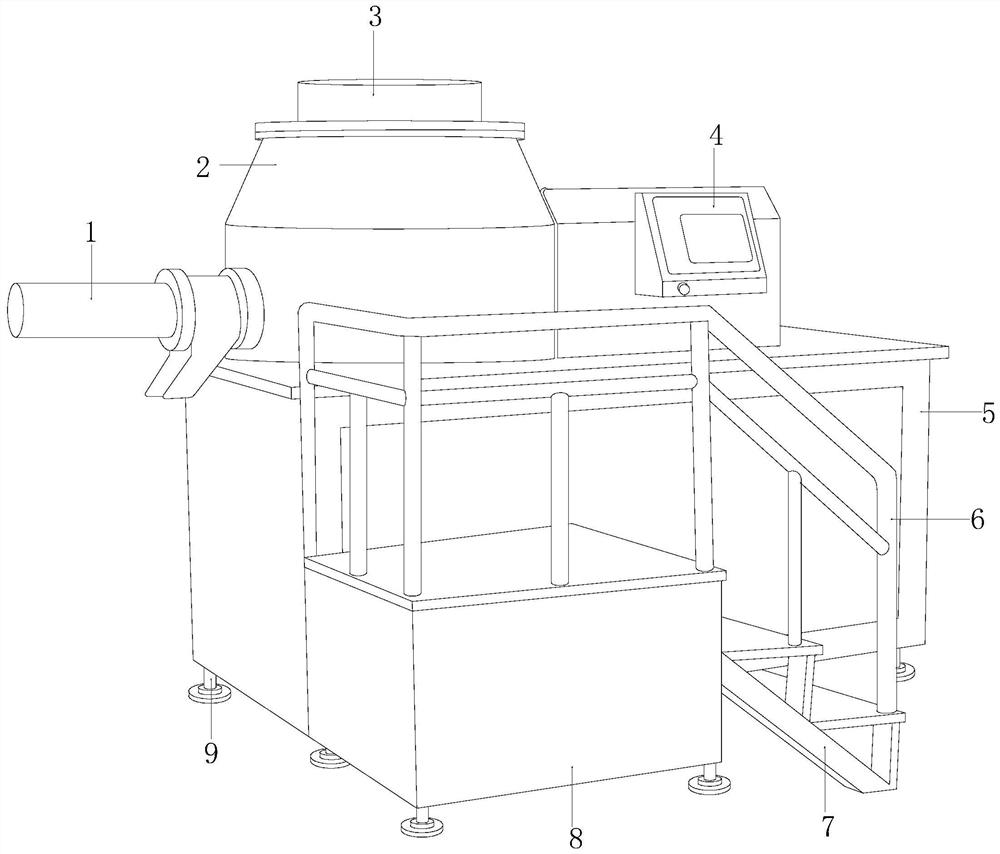

[0030] see figure 1 , the present invention provides a technical solution: a biomacromolecule drug granulator, the structure of which includes a discharge port 1, a processing device 2, a feed port 3, an operation panel 4, a body 5, a guardrail 6, a staircase 7, Platform 8, support feet 9, the discharge port 1 communicates with the processing device 2, the discharge port 1 communicates with the feed port 3 through the processing device 2, an operation panel 4 is provided on one side of the processing device 2 and The two are energized, the processing device 2 and the operation panel 4 are all arranged on the body 5, the body 5 is connected to the platform 8 and the stairs 7, and the platform 8 and the stairs 7 are provided with guardrails 6, the body 5 and the bottom of platform 8 are connected with supporting feet 9;

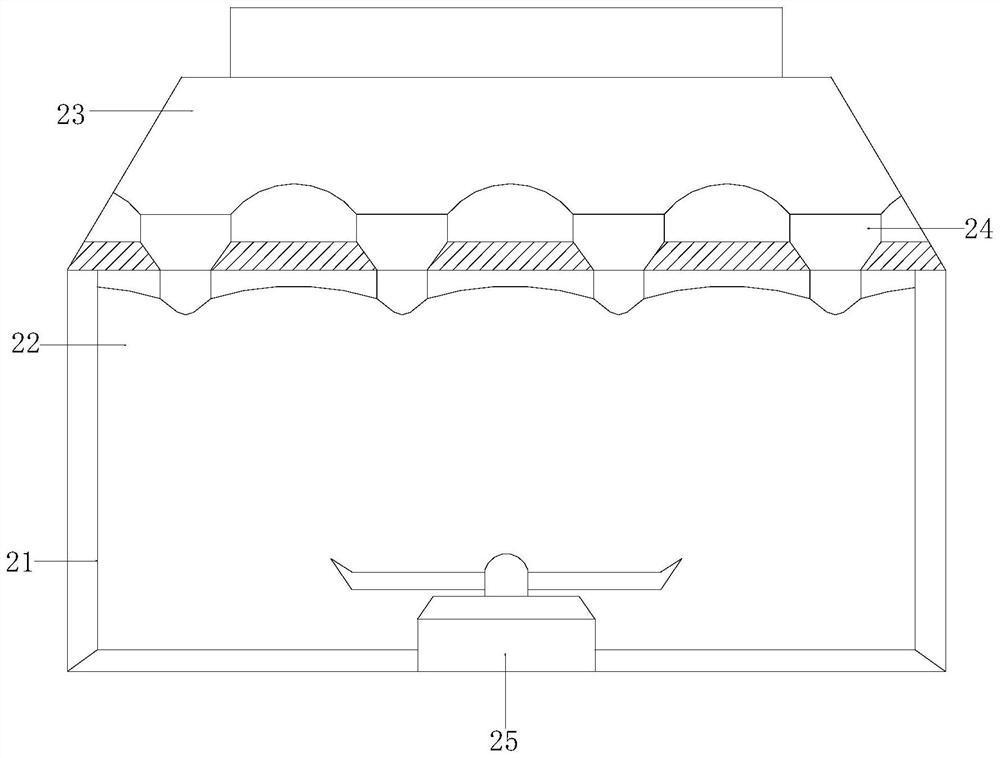

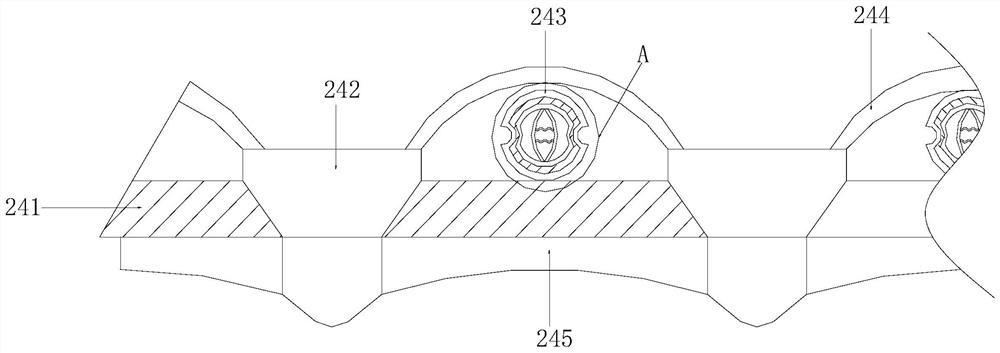

[0031] see figure 2 The processing device 2 includes a non-stick component 21, a frame body 22, a receiving chamber 23, a barrier guide 24, and an agitator...

Embodiment 2

[0043] see figure 1 , the present invention provides a technical solution: a biomacromolecule drug granulator, the structure of which includes a discharge port 1, a processing device 2, a feed port 3, an operation panel 4, a body 5, a guardrail 6, a staircase 7, Platform 8, support feet 9, the discharge port 1 communicates with the processing device 2, the discharge port 1 communicates with the feed port 3 through the processing device 2, an operation panel 4 is provided on one side of the processing device 2 and The two are energized, the processing device 2 and the operation panel 4 are all arranged on the body 5, the body 5 is connected to the platform 8 and the stairs 7, and the platform 8 and the stairs 7 are provided with guardrails 6, the body 5 and the bottom of platform 8 are connected with supporting feet 9;

[0044] see figure 2 The processing device 2 includes a non-stick component 21, a frame body 22, a receiving chamber 23, a barrier guide 24, and an agitator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com