Method for continuously producing pultrusion epoxy glass fiber boards for ultra-long time

An epoxy glass fiber, ultra-long-term technology, applied to other household appliances, household appliances, flat products, etc., can solve the problems of increased surface defects, product defects, fatigue performance reduction, etc., to delay aging glue and improve production Efficiency, the effect of solving the problem of old glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

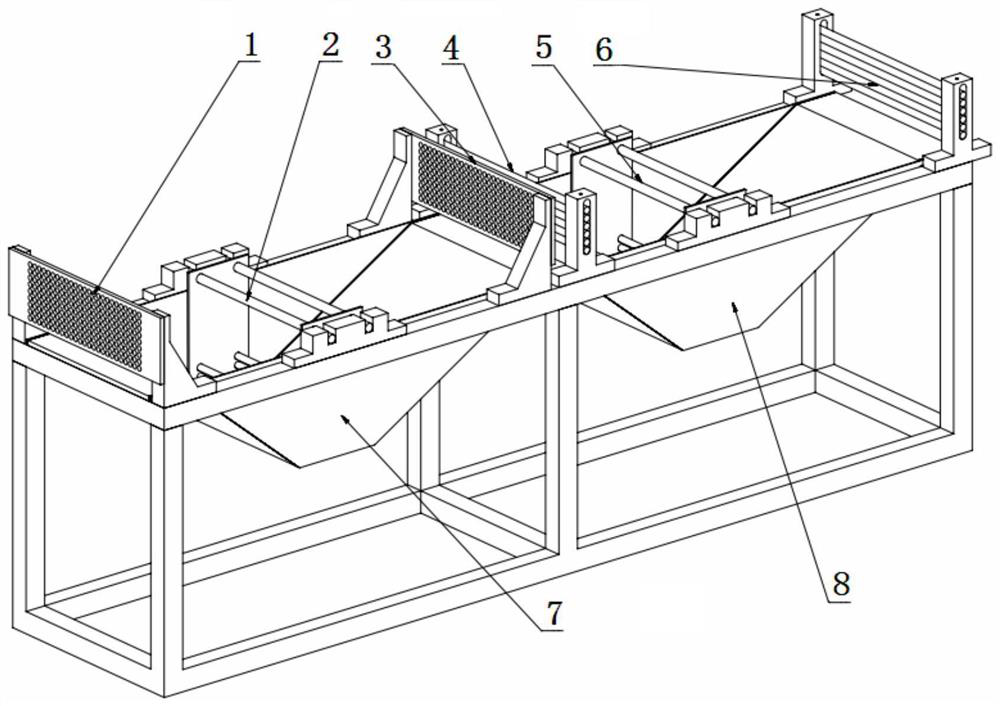

[0020] like figure 1 As shown, a method for continuous production of a pultruded epoxy glass fiber board for a long time, comprising steps:

[0021] 1) Yarn withdrawal from the creel: pull out the yarn from the yarn cluster, and gather the required amount of yarn together through the creel device;

[0022] 2) Yarn spreading and guiding: guide the yarn from the yarn cluster to the next step, and spread the yarn to relieve the twist of the yarn and make the yarn soft;

[0023] 3) Double glue tank dipping: let the yarn fully soak in the dipping tank, the dipping tank includes the first dipping tank 7 and the second dipping tank 8; first dip the yarn into the first dipping tank 7 , then the yarn immersed in the first dipping tank 7 is immersed in the second dipping tank 8; when the yarn is immersed in the second dipping tank 8, the first dipping tank 7 is cleaned; When dipping into the first dipping tank 7, clean the second dipping tank 8, and reciprocate in this way to avoid th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com