Paper pulp residue filtering plate with micropore adjustable structure

A pulp and filter residue technology, applied in textiles and papermaking, fiber raw material processing, etc., can solve the problems of filter hole blockage, low efficiency of pulp moisture separation, easy adhesion to filter holes, etc., to improve efficiency and relieve blockage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

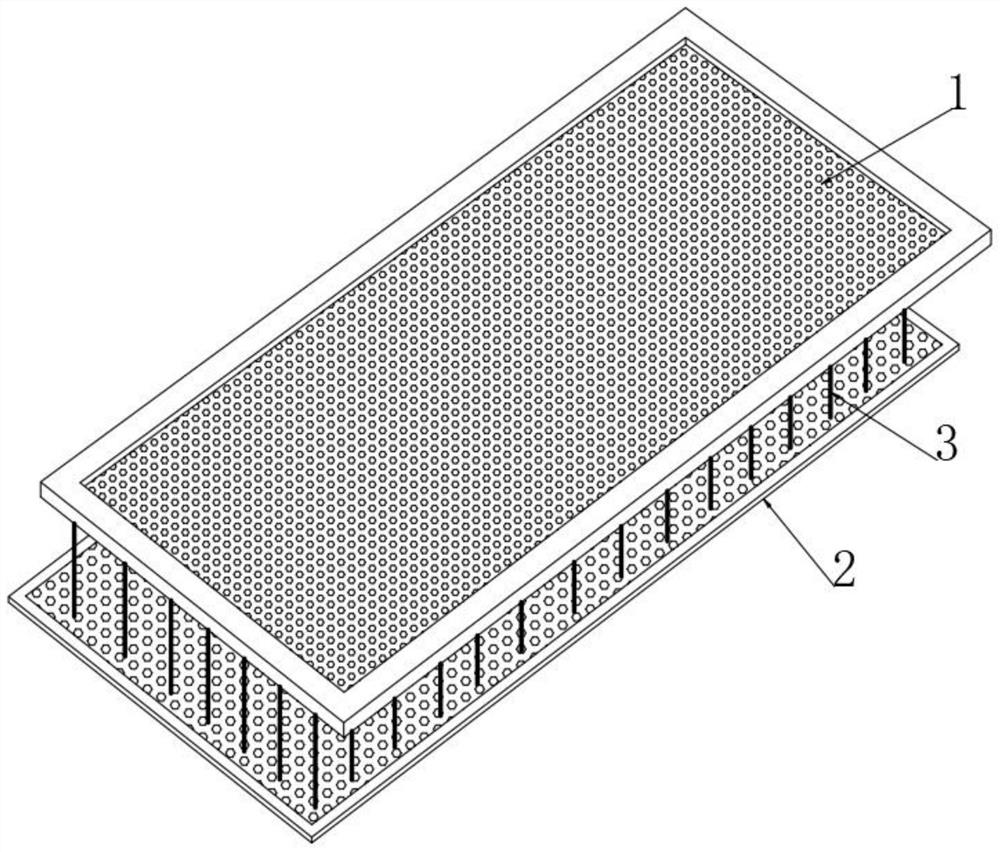

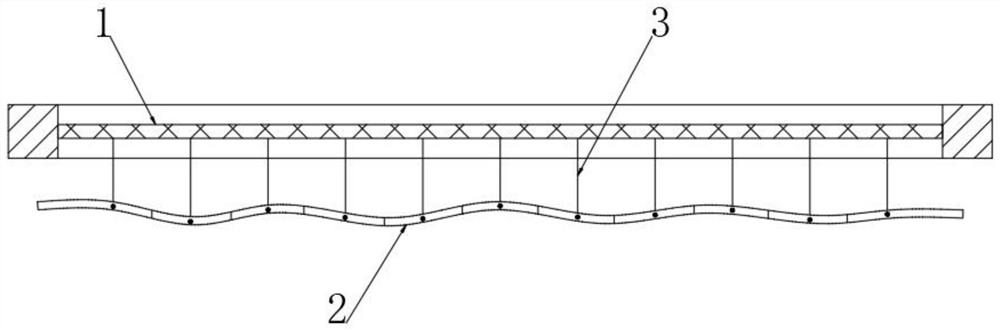

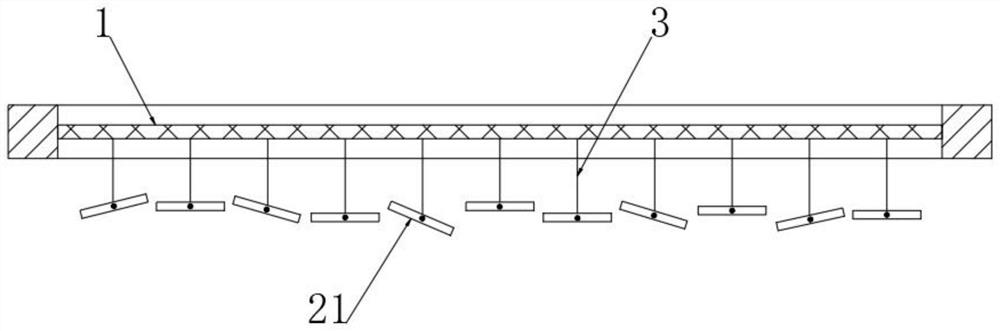

[0042] see figure 1 with Figure 10 , a paper pulp filter residue plate with a microporous adjustable structure, on the basis of the prior art, a structure of a double screen plate with adjustable holes is added to the filter holes of the filter residue plate body, please refer to figure 2 with Figure 4-5The hole-adjusting double screen plate includes a plurality of hole-adjusting rings 4 respectively matched with the filter holes, a plurality of connecting rods 7 connected between two adjacent hole-adjusting rings 4, and a lower guide rope connected in the hole-adjusting rings 4 3 and the reversible self-separating sheet 2 connected under a plurality of lower guide ropes 3, a plurality of uniformly distributed moving comb sheets 5 and fixed comb sheets 6 are fixedly connected inside the adjusting hole ring 4, and a plurality of fixed comb sheets 6 are located at the bottom of the moving comb The lower part of the sheet 5 makes the filter residue plate present the structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com