Movable building construction device

A mobile technology for building construction, applied in shaft equipment, shaft lining, tunnel lining, etc., can solve the problems of high long-term rental price, material consumption, and prolonging the construction period, so as to achieve good overall stability, shorten the construction period, simplify The effect of the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

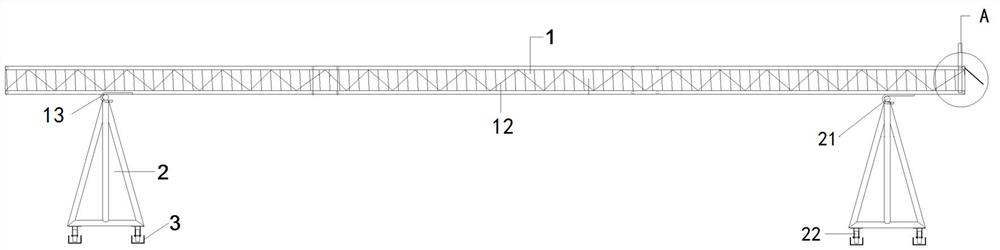

[0024] Embodiment of a kind of movable building construction device of the present invention:

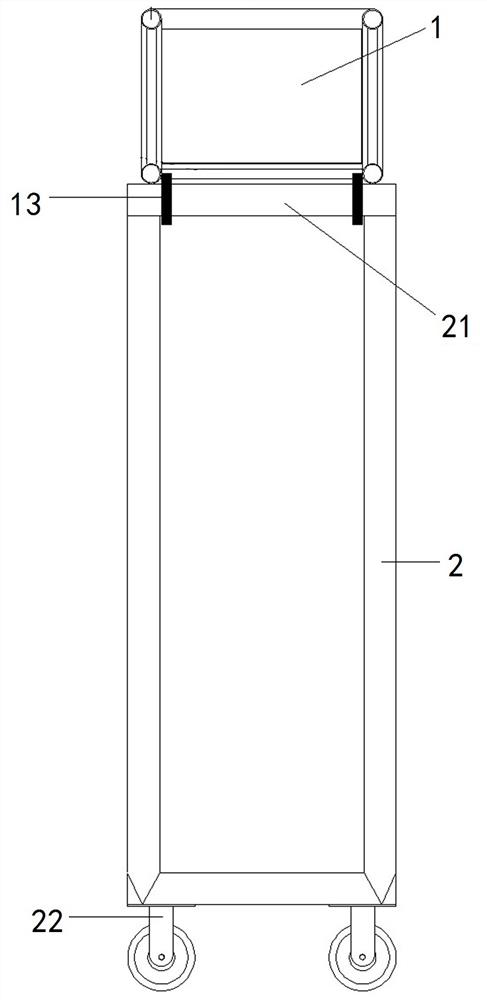

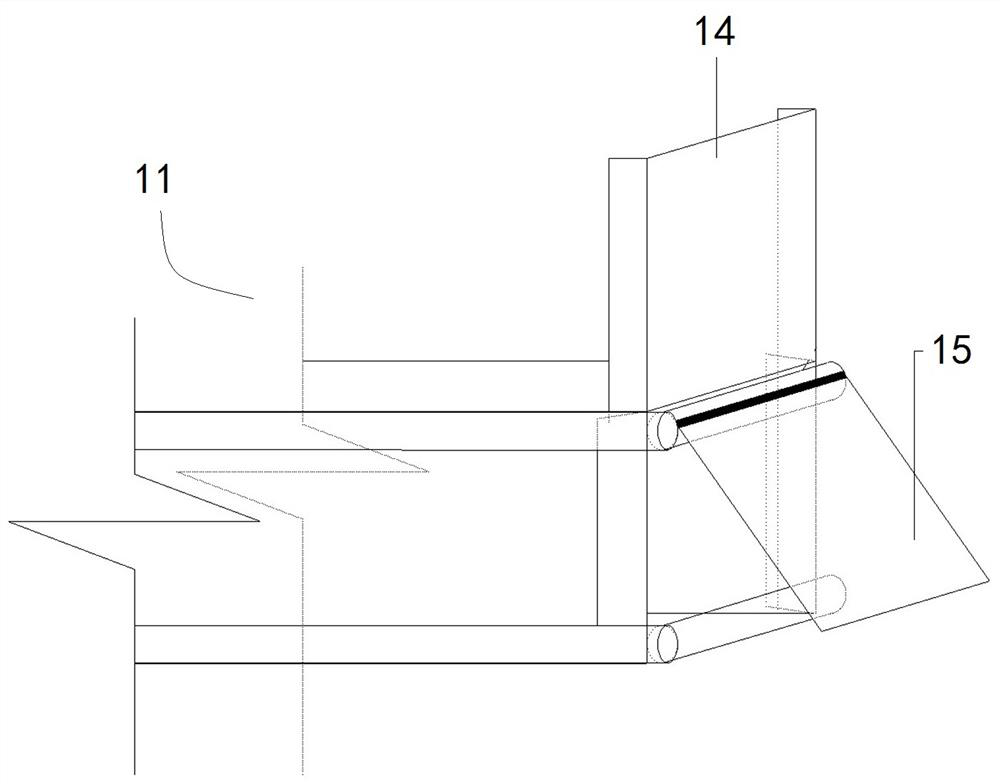

[0025] The concrete structure of a kind of movable building construction device of the present invention is as follows: Figure 1 to Figure 8 As shown, it includes a chute main body 1, a sliding bracket 2, a slide rail 3, a formwork frame unit, a connecting rod 7 and a connecting beam 8. The chute main body 1 includes a baffle plate assembly 11 and a plurality of chute units 12 connected in series end to end, two adjacent chute units 12 are plugged in and connected, and bolts are installed at the plugged connections for further fixing effect . The lower end of the chute unit 12 is fixed with a support ring 13, and the rear end of the support ring 13 has an opening.

[0026] The sliding bracket 2 includes a connecting rod 21 at the upper end, the cross-sectional shape of the connecting rod 21 is circular, and the shape of the support ring 6 matches the shape of the connecting rod 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com