Slurry field sampling device in goaf filling process and use method thereof

A technology of on-site sampling and goaf, applied in the direction of sampling devices, etc., can solve the problems of inability to obtain in-situ slurry, low sampling success rate, insufficient sampling depth, etc., and achieve simple structure, high sampling success rate, and rapid installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0037] The invention provides an on-site sampling device for slurry during goaf filling and a use method.

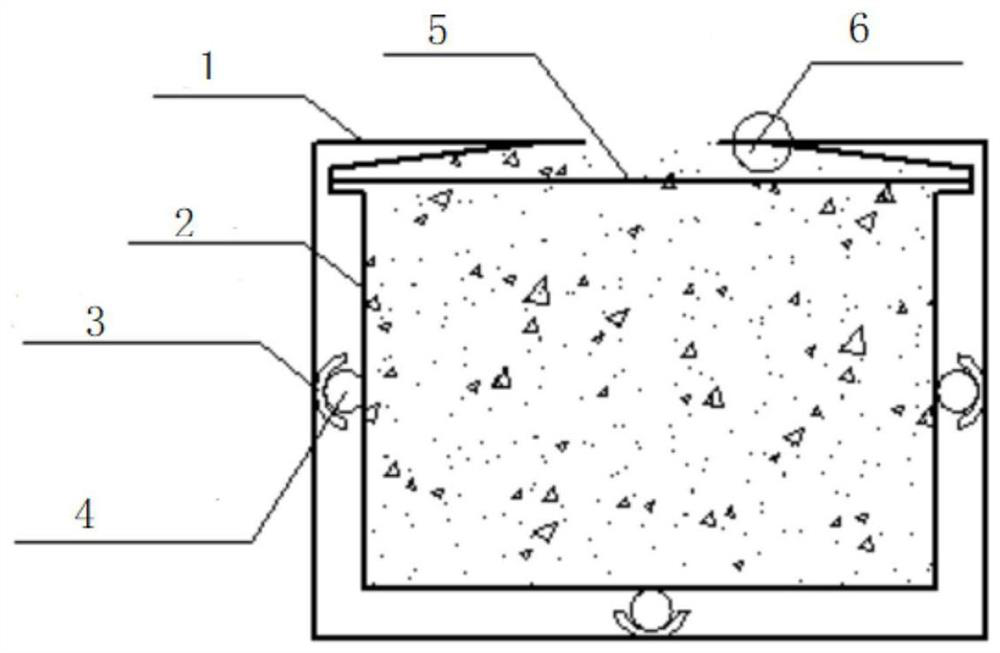

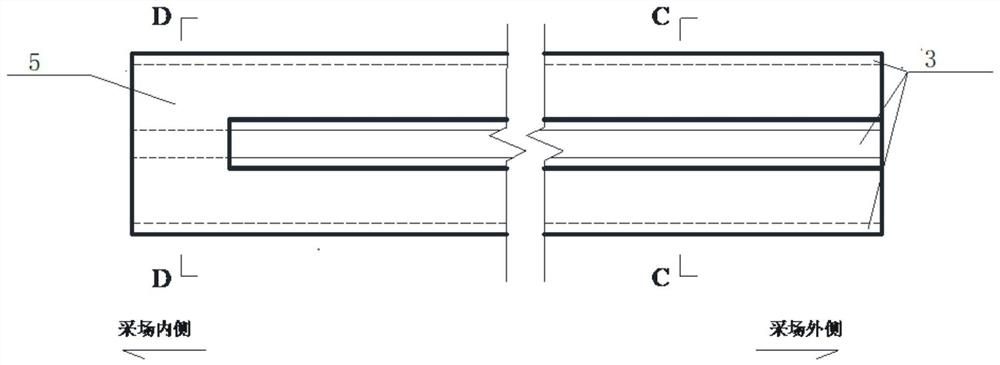

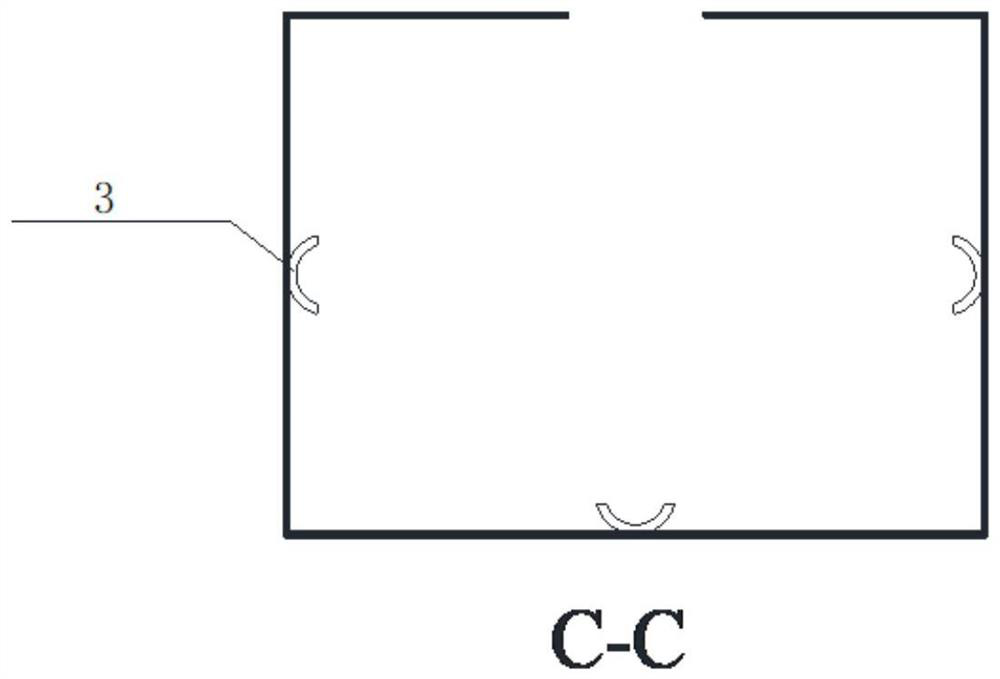

[0038] like figure 1 and Figure 8As shown, the device includes an outer casing 1, an inner casing 2, a cover plate 5 and an L-shaped steel plate bracket 12, the outer casing 1 is provided with an outer casing guide rail 3, and the inner casing 2 is provided with an inner casing slide rail 4 and a chute 10. The slide rail 4 of the inner casing is aligned with the guide rail 3 of the outer casing, so that the inner casing 2 is inserted into the outer casing 1, the cover plate 5 is inserted into the chute 10, and the outer casing 1 is fixed by a pair of L-shaped steel plate brackets 12 and the bottom plate with expansion bolts 13 fixed.

[0039] l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com