Titanium dioxide production microfiltration washing device and process

A washing device and titanium dioxide technology, applied in the field of titanium dioxide, can solve the problems of large manpower, material resources, waste of water resources, large water consumption, etc., and achieve the effects of improving recovery rate, uniform pore size, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

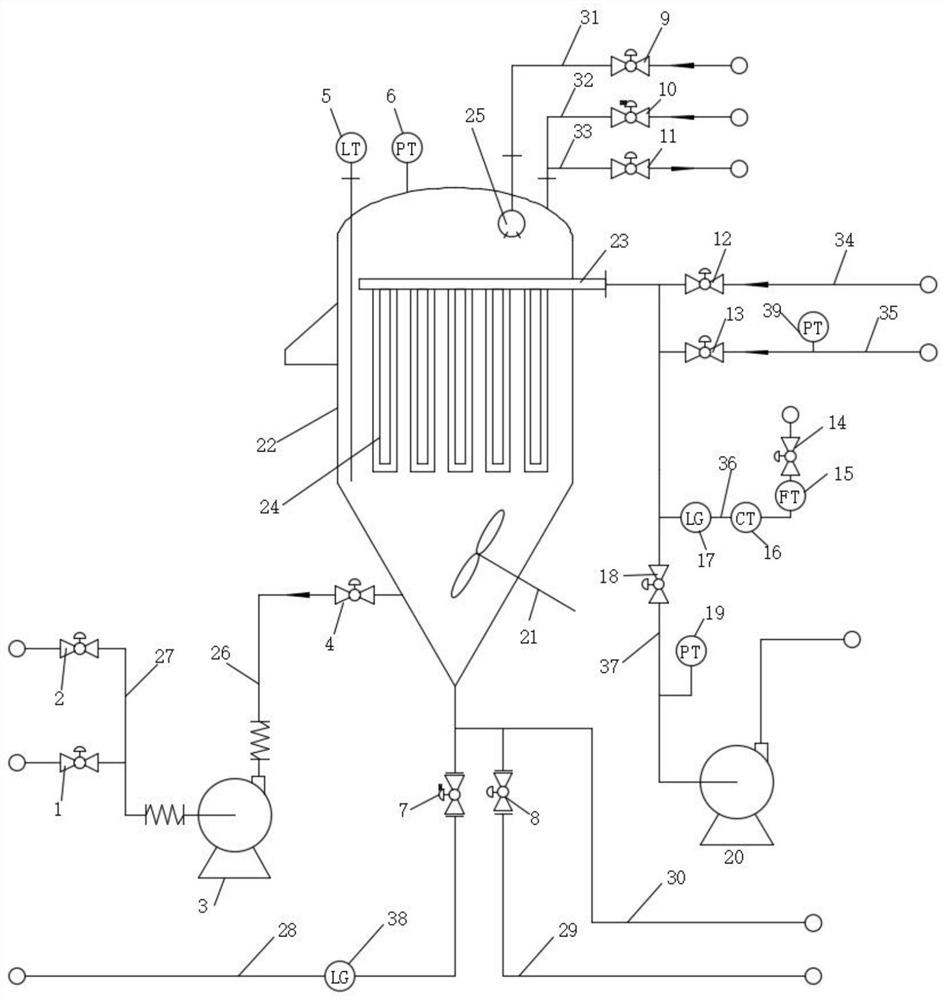

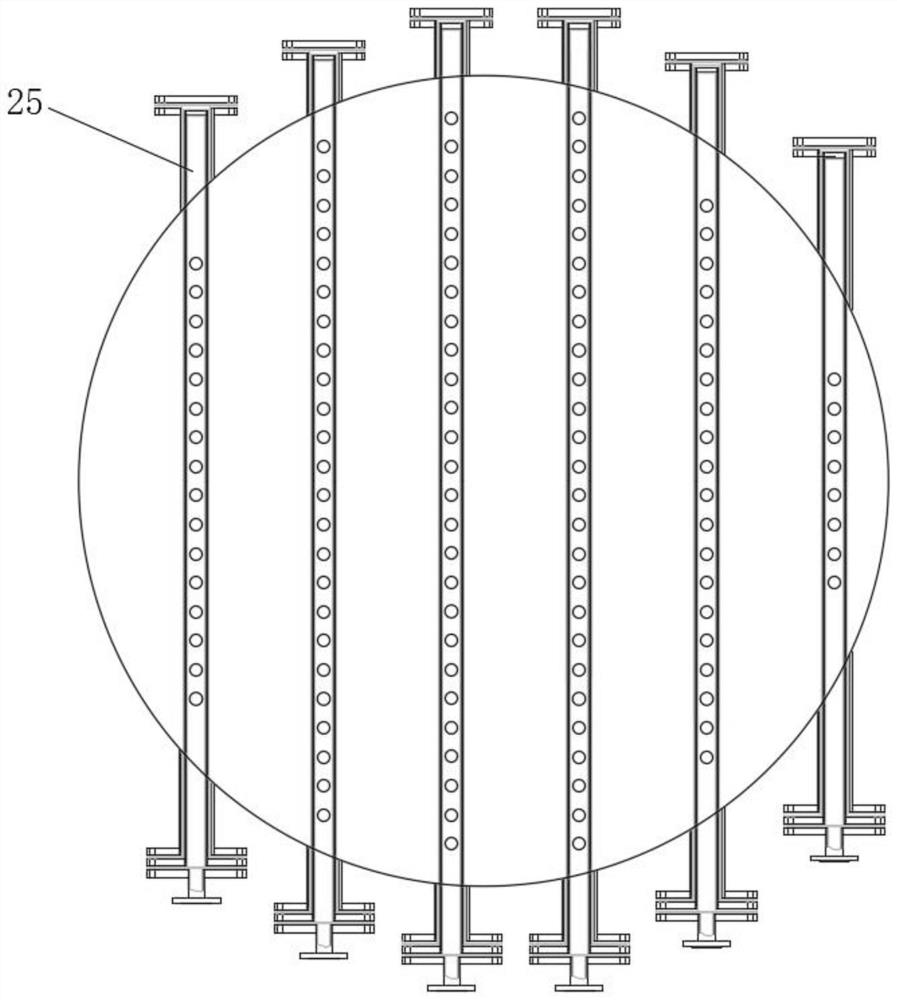

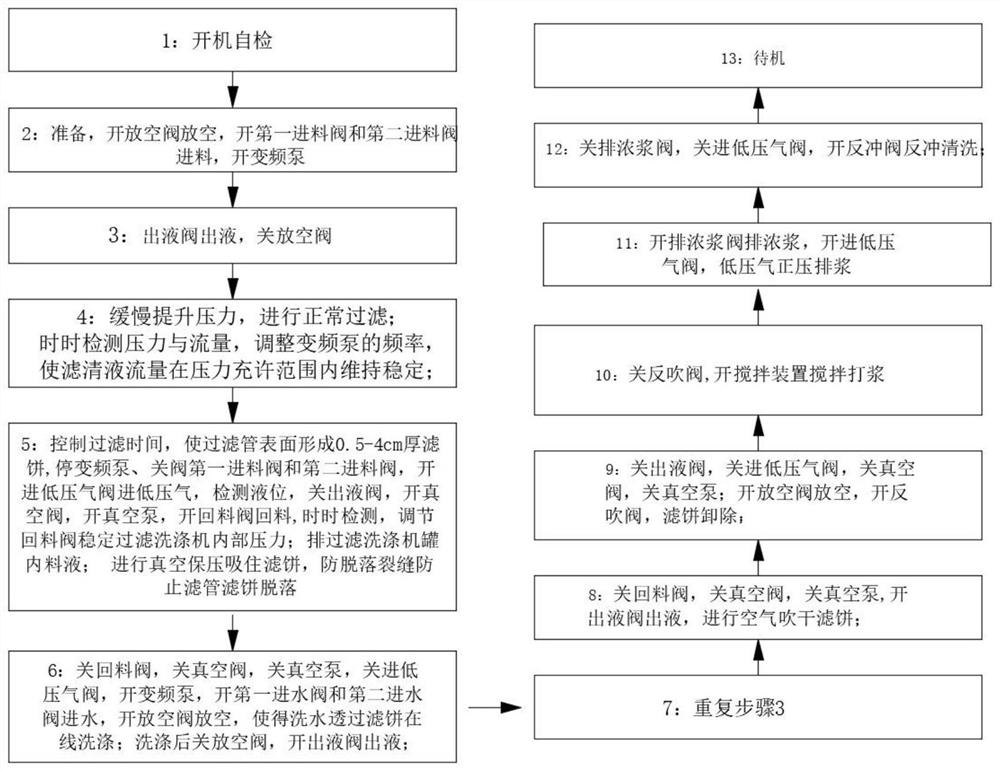

[0032] Embodiment: a kind of titanium dioxide produces microfiltration washing device, as figure 1 As shown, the filter washing machine 22 is included, and the filter washing machine 22 is provided with a row pipe 23, and the row pipe 23 is connected with a plurality of filter pipes 24; in the present embodiment, the filter pipe 24 is provided with a microporous filter medium, such as figure 2 As shown, the microporous filter medium is sintered ultra-high molecular weight polyethylene or other metal and non-metallic powders, preferably sintered ultra-high molecular weight polyethylene; the length of the microporous filter medium is 0.2-2m; the microporous The filter medium is arranged in a rectangular arrangement; the ratio of the length of the microporous filter medium to the outer diameter is less than 52.5; 100-400mm, the above parameters can be adjusted through actual production; the inside of the filter washing machine 22 is provided with a stirring device 21, and the st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com