Soybean machining system and machining method

A processing system, soybean technology, applied in cocoa, grain processing, food science, etc., can solve problems such as being unsuitable for soybean processing operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

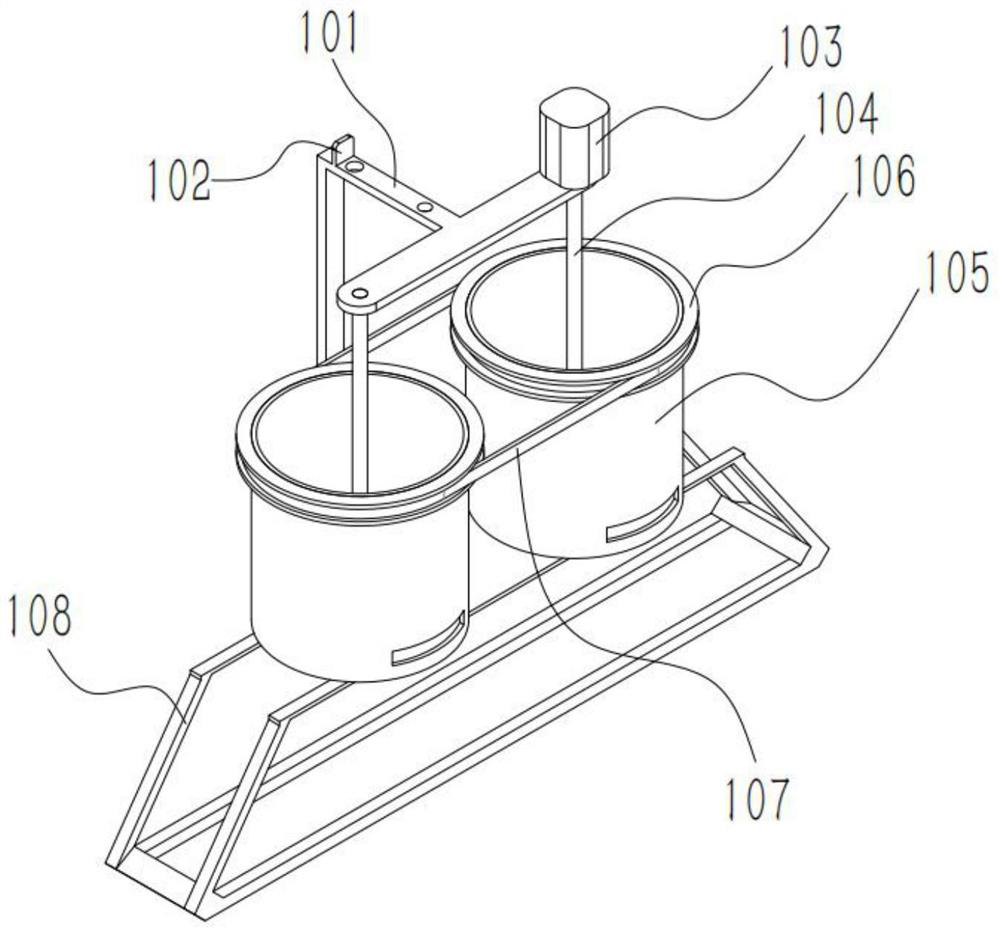

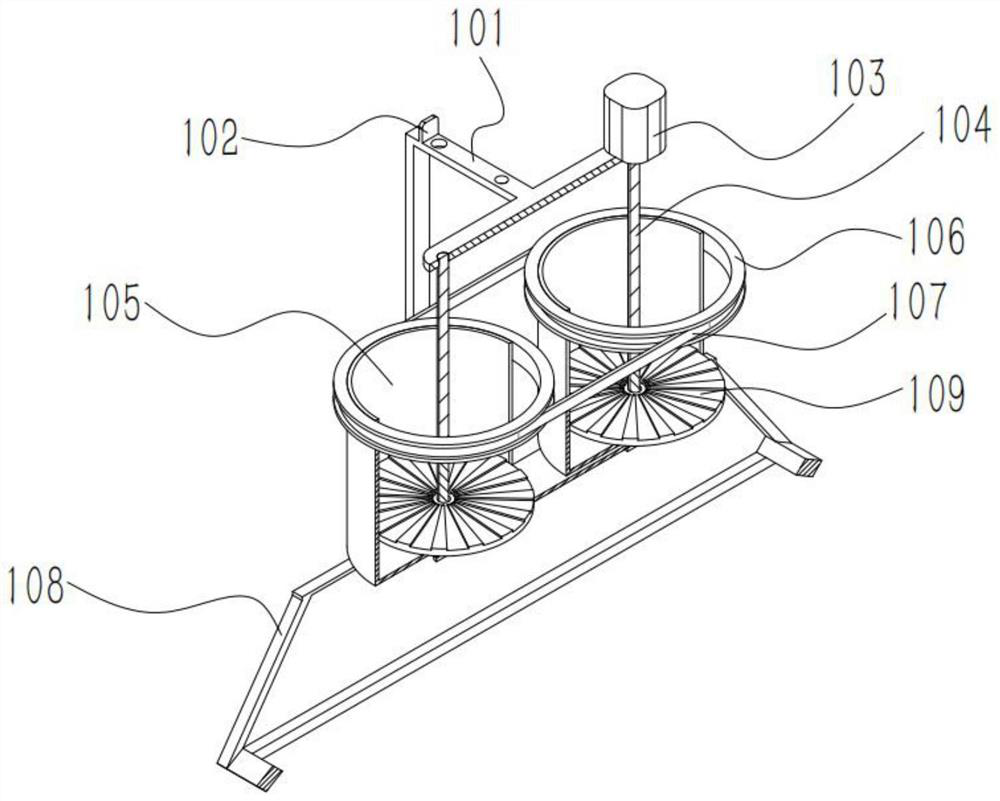

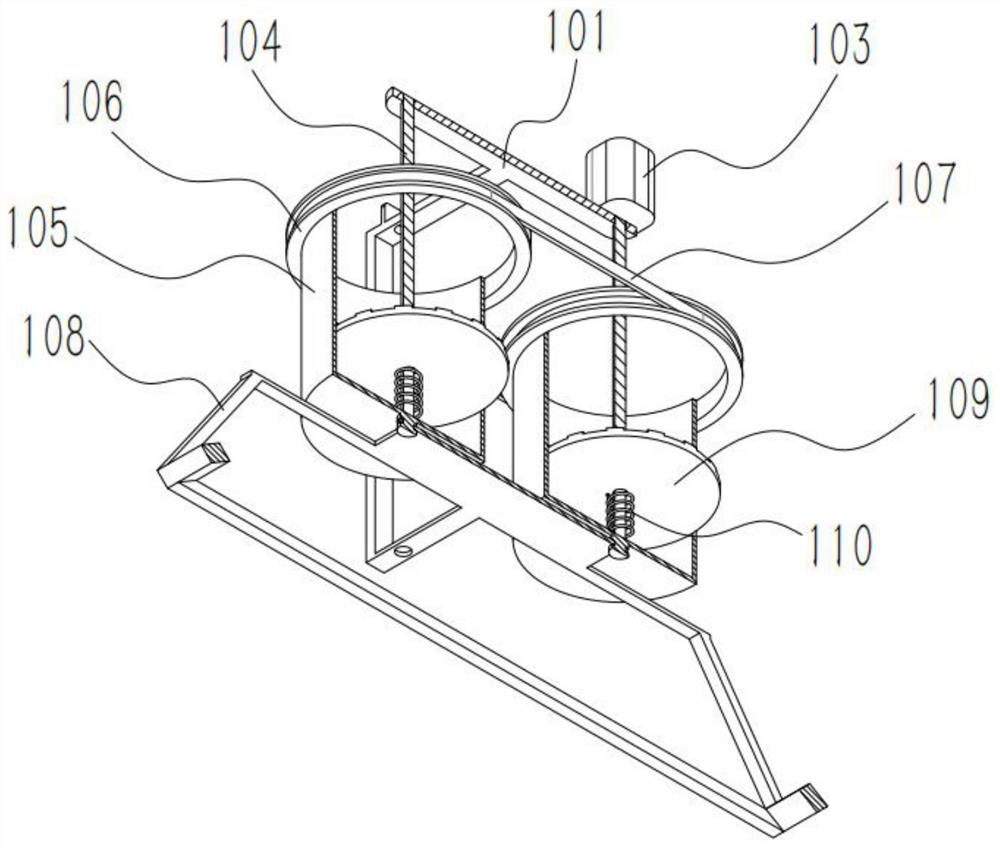

[0025] This part is based on figure 1 , 2 The work process expressed in and 3 is: the left side of the upper end of the processing frame 101 is provided with a base 102, the bottom end of the processing frame 101 is fixedly connected with an underframe 108, and the front and rear ends of the upper side of the underframe 108 are respectively rotated and connected to a processing frame. There are two barrels 105 and two rotating rods 104. The bottom ends of the two rotating rods 104 are fixedly connected to the middle parts of the two processing barrels 105 respectively. On the upper end of 104, the output shaft of motor I 103 is affixed to the rotating rod 104 located at the front end through a coupling. The two pulleys 106 are connected in transmission.

[0026] For further explanation, in order to facilitate the processing of soybeans at home, and to facilitate the mixing of milk after soybean processing, firstly, the driving motor I103 drives the rotating rod 104 to rotate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com