Coarse and fine material screening device

A screening device and technology of thickness, applied in the field of material screening devices, can solve the problems of screening one size and inaccurate screening, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

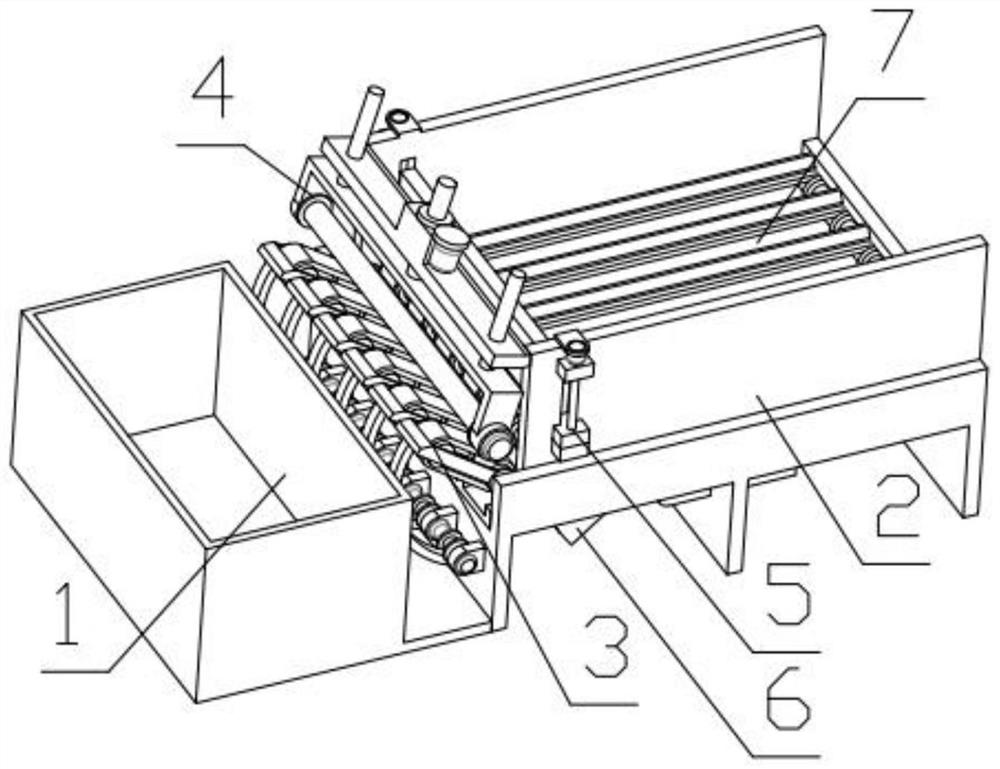

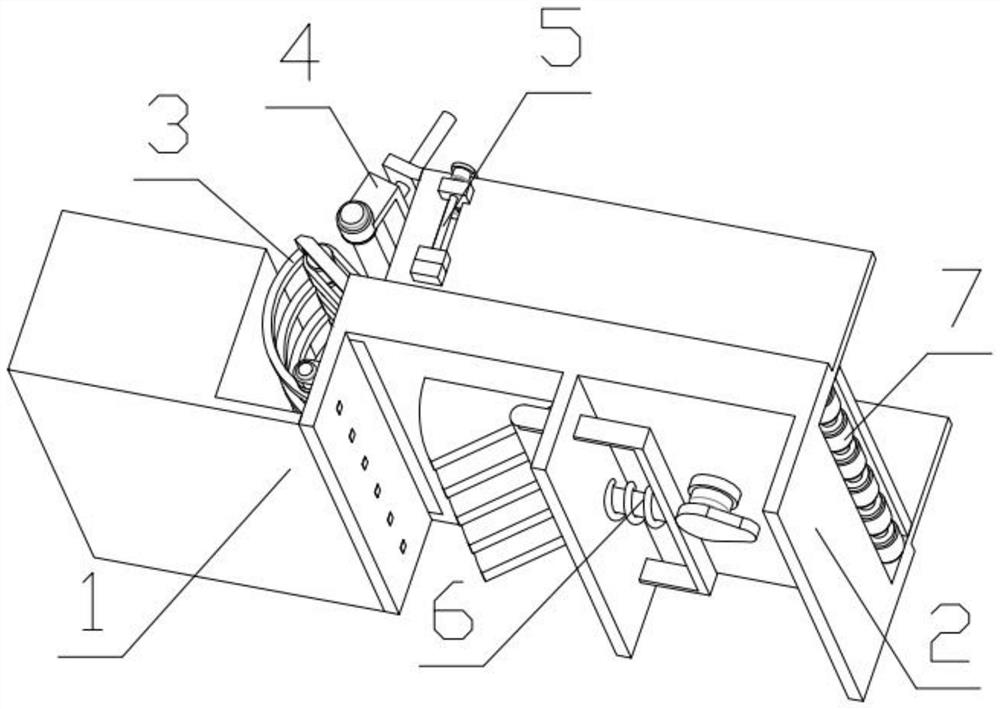

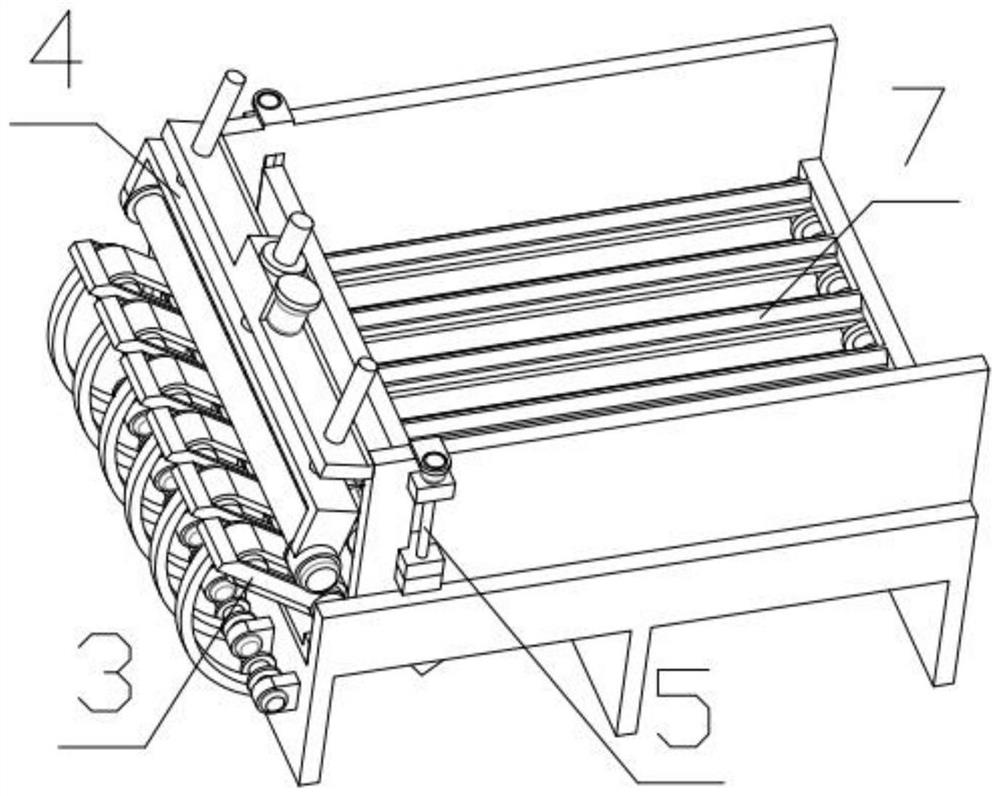

[0038] Combine below Figure 1-17 Description of this embodiment, a material coarse and fine screening device, including a box 1, a mounting frame 2, a discharge mechanism 3, an auxiliary discharge mechanism 4, a coarse and fine screening mechanism 5, a disturbing mechanism 6 and a transmission mechanism 7, the described The box 1 is fixedly installed on the installation frame 2, the discharge mechanism 3 is fixedly installed on the installation frame 2, the auxiliary discharge mechanism 4 is fixedly installed on the installation frame 2, the coarse and fine screening mechanism 5 is fixedly installed on the installation frame 2, and the installation frame A disturbing mechanism 6 is fixedly installed on the 2, and a transmission mechanism 7 is fixedly installed on the mounting frame 2, and the transmission mechanism 7 is connected with the discharge mechanism 3 in contact.

specific Embodiment approach 2

[0039] Combine below Figure 1-17 Describe this embodiment, this embodiment will further explain the first embodiment, the discharge mechanism 3 includes multiple sets of mounting frames 3-1, distance square frames 3-2, arc-shaped toothed parts 3-3, and adjustment motors 3 -4, adjusting gear 3-5, motor mounting frame 3-6, first rotating shaft 3-7, short rubber conveyor belt 3-8, second rotating shaft 3-9, multiple groups of mounting frames 3-1 are fixedly installed on the installation On the frame 2, the spacing square frame 3-2 is hinged with multiple sets of mounting brackets 3-1, and the first rotating shaft 3-7 is rotated and installed in the groove provided on the spacing square frame 3-2, and the second rotating shaft 3-7 9 Rotation is installed in the groove provided on the spacing square frame 3-2, the short rubber conveyor belt 3-8 is wound on the second rotating shaft 3-9, and the short rubber conveyor belt 3-8 is wound on the first rotating shaft 3-9 7, the spacing...

specific Embodiment approach 3

[0040] Combine below Figure 1-17 Describe this embodiment, this embodiment will further explain the first embodiment, the auxiliary discharge mechanism 4 includes an external rubber push shaft 4-1, a transmission motor 4-2, a drive frame 4-3, a limit column 4- 4. Threaded column 4-5, internal thread gear ring 4-6, lifting gear 4-7, lifting motor 4-8, fixed strip 4-9, fixed strip 4-9 is fixedly installed on the mounting frame 2, fixed The internally threaded gear ring 4-6 is installed in the groove provided on the strip 4-9, and the internally threaded gear ring 4-6 is threadedly connected with the threaded column 4-5, and the threaded column 4-5 passes through the fixed strip 4- The through hole provided on 9, the limit post 4-4 is slidably installed in the through hole provided on the fixed strip 4-9, the stop post 4-4 is fixedly installed on the drive frame 4-3, and the drive frame 4-3 A threaded column 4-5 is fixedly installed, an external rubber push shaft 4-1 is rotatab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com