Welding device for hairpin motor coil

A welding device and coil technology, applied in auxiliary devices, welding equipment, welding equipment, etc., can solve the problem of affecting product quality, difficulty in ensuring the final position of the end of the flat wire group, and difficulty in ensuring that each end of the wire moves to the required position, etc. problem, to achieve the effect that the quality is not easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present application will be further described below with reference to the accompanying drawings.

[0044] The welding apparatus of a card motor coil disclosed herein can automatically position the wire of the flat line group by mechanical structure, so that the positioning of the wire head is more accurate, thereby improving the mass of the processed partial flat line group.

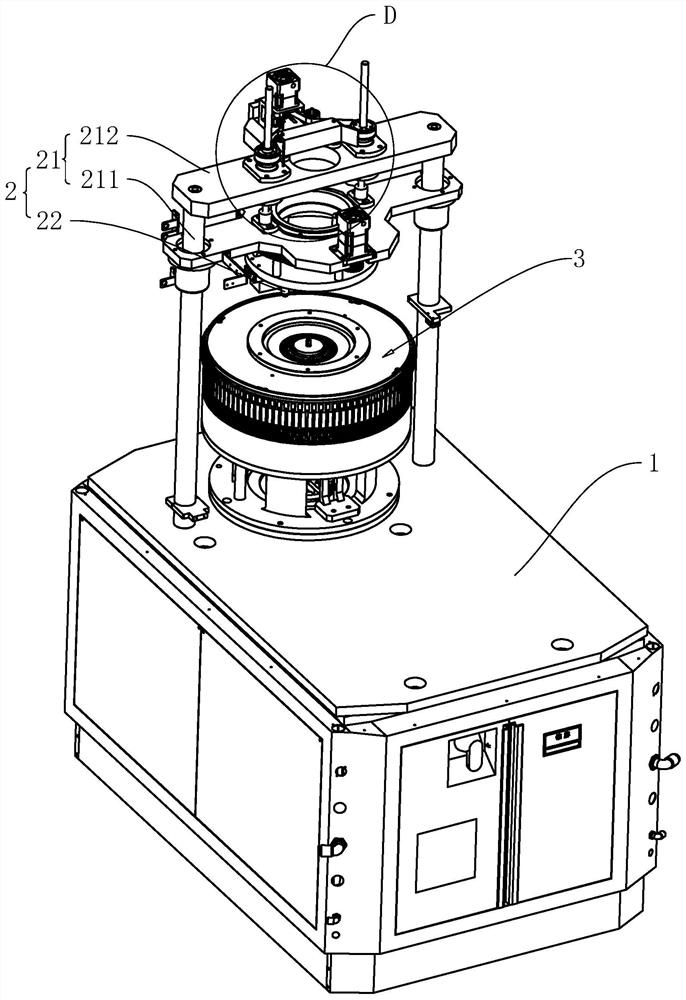

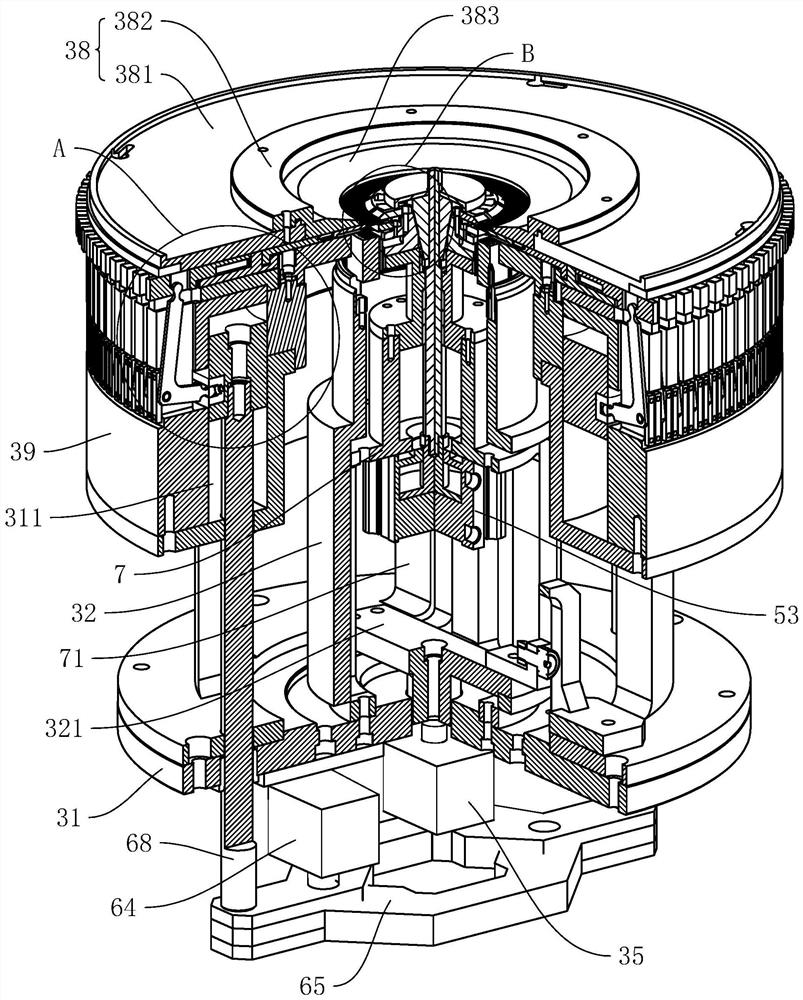

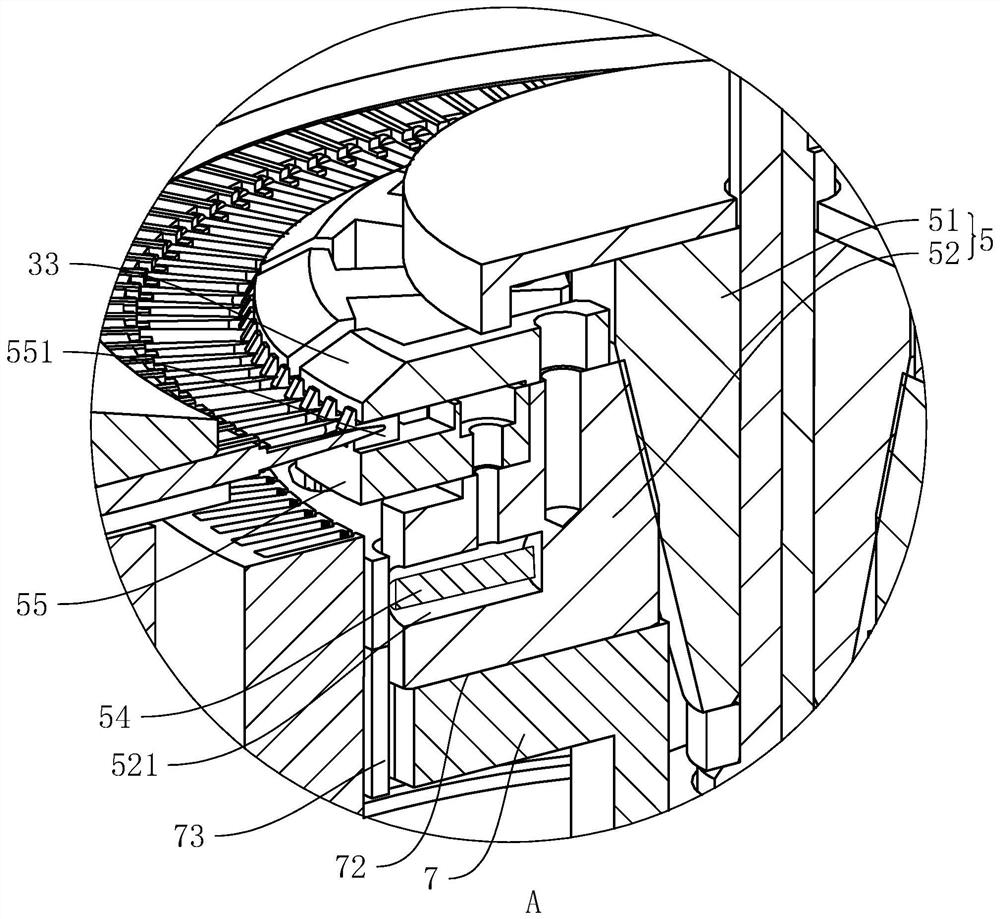

[0045] like figure 1 As shown, including the frame body 1, the welding mechanism 2 provided on the frame body 1 and a clamp 3 that positions the stator. like figure 2 with image 3 As shown, the jig 3 includes a base 31 set in a cylindrical and an upper opening, and the coaxial is disposed in the lumen of the base 31 and is used to hold a top material cover 32 of the positioning stator, and a number of internal blocks 33 of the line head of the flat line group. And several outer blocks 34. The base 31 is fixed to the end surface of the frame body 1 using a bolt, and the lower end thereof is axially...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com