A preparation method of deformed superalloy wide thin strip

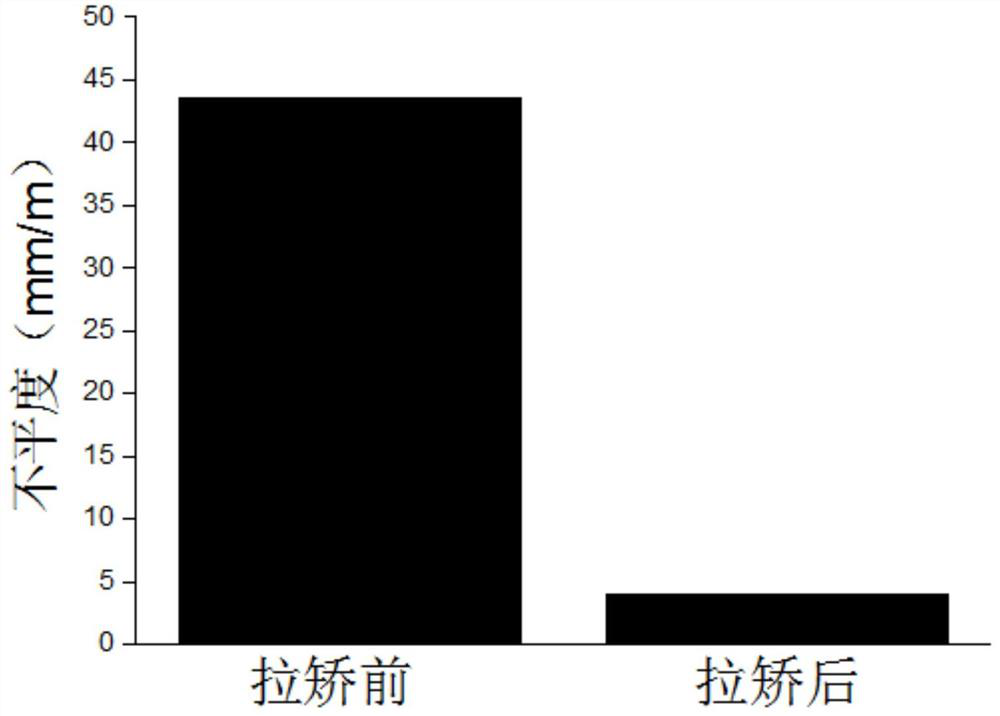

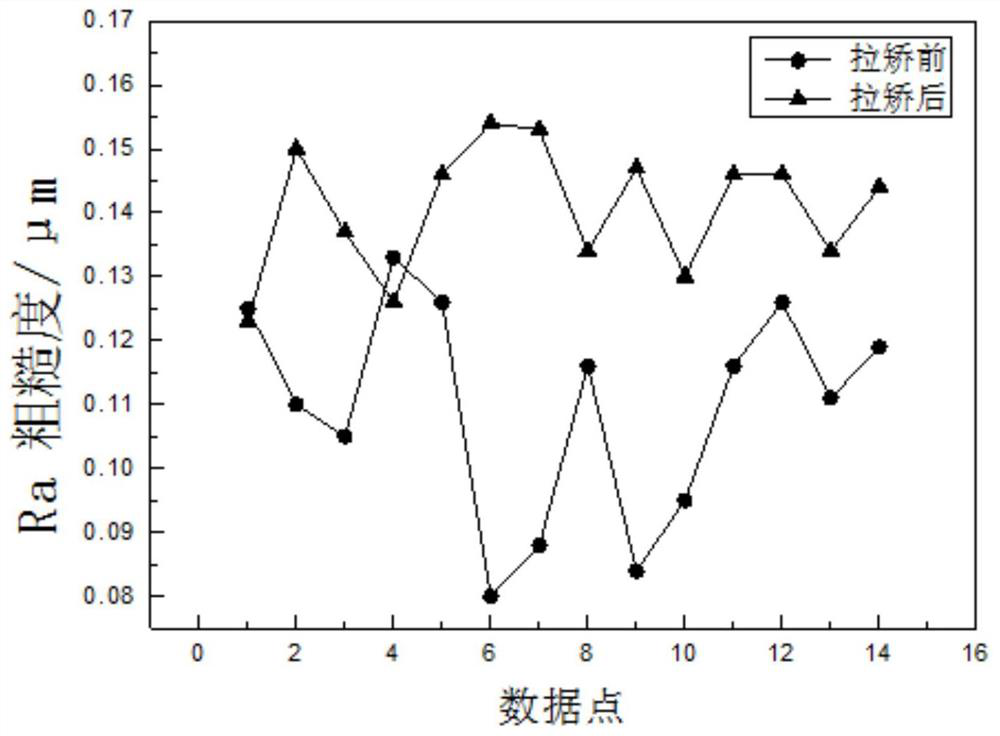

A deformed superalloy, wide-width technology, which is applied in the field of preparation of deformed superalloy wide and thin strips, can solve the problems of coiling and rolling of wide-width cold-rolled strips, microstructure, performance, plate thickness, shape and surface quality, production Problems such as equipment, technical level, product quality gap, equipment and technical capabilities cannot be reached, etc., to achieve the effect of improving process plasticity and forming ability, high product quality, and improving flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

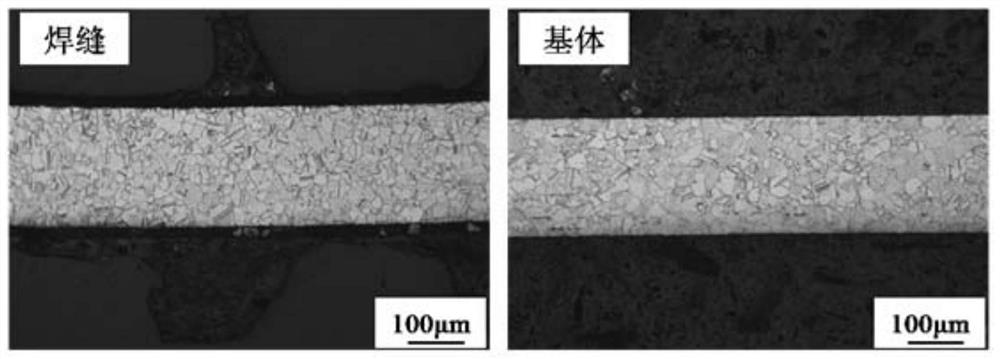

[0048] Several sheets of deformed superalloy GH4169 with a thickness of 1.5mm, a width of 620mm and a length of 2500mm were butted by plasma arc welding and welded into rolls. The welding voltage was 30V, the welding current was 200A, and the welding speed was 20 m / h. , Control the plasma gas consumption to 350 liters / hour.

[0049] The sheets welded into coils are warmly rolled and billeted on the warm rolling unit, and the warm rolling temperature is controlled to be 450 °C, and the warm rolling is carried out according to 3 rolling passes. 22%, the rolling speed is controlled at 10 m / min per pass, the rolling force is controlled at 600 KN per pass, and the initial strip with a thickness of 0.7 mm is rolled.

[0050] Put the 0.7mm thick initial strip in H 2 SO 4 Pickling is carried out in the pickling tank with HCl to remove the surface oxidation color. The 0.7mm thick initial strip after pickling is softened and annealed in a continuous bright annealing furnace in a hydr...

Embodiment 2

[0055] Several sheets of deformed superalloy GH4738 with a thickness of 2.0mm, a width of 630mm and a length of 2800mm were butted by plasma arc welding and welded into rolls. The welding voltage was 40V, the welding current was 250A, and the welding speed was 25 m / h. , Control the plasma gas consumption to 370 liters / hour.

[0056] The sheets welded into coils are warmly rolled and billeted on the warm rolling unit, and the warm rolling temperature is controlled to be 430 ° C, and the warm rolling is carried out according to 3 rolling passes, and the control pass deformations are 25%, 26.7%, 27%, the rolling speed is controlled at 12 m / min per pass, the rolling force is controlled at 500 KN per pass, and the initial strip with a thickness of 0.8 mm is rolled. Put the 0.8mm thick initial strip in H 2 SO 4 Pickling is carried out in the pickling tank with HCl to remove the surface oxidation color.

[0057] The 0.8mm thick initial strip after pickling was softened and anneale...

Embodiment 3

[0062] Several sheets of deformed superalloy GH3536 with a thickness of 1.8mm, a width of 610mm and a length of 2300mm were butted by plasma arc welding and welded into rolls with a welding voltage of 20V, a welding current of 300A and a welding speed of 30m / h , Control the plasma gas consumption to 400 liters / hour.

[0063] The sheets welded into coils are warmly rolled and billeted on the warm rolling unit, and the warm rolling temperature is controlled to 500 ° C, and the warm rolling is carried out according to 3 rolling passes, and the control pass deformations are 25%, 25.9%, 25%, the rolling speed is controlled at 15 m / min per pass, the rolling force is controlled at 700 KN per pass, and the initial strip with a thickness of 0.75 mm is rolled. Put the 0.75mm thick initial strip in H 2 SO 4 Pickling is carried out in the pickling tank with HCl to remove the surface oxidation color.

[0064]The 0.75mm thick initial strip after pickling was softened and annealed in a co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com