Prefabricated concrete building block forming manufacturing machine and manufacturing method

A concrete and block technology, applied in the field of concrete prefabricated block forming machinery and production, can solve the problems of poor exhaust effect, ratio error of raw material mixing, easy adhesion on the inner wall of the tank, etc., and achieve the purpose of improving the service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to achieve the technical means of the present invention, creative features, to achieve the purpose and effect is easy to understand understanding of the present invention will be further explained.

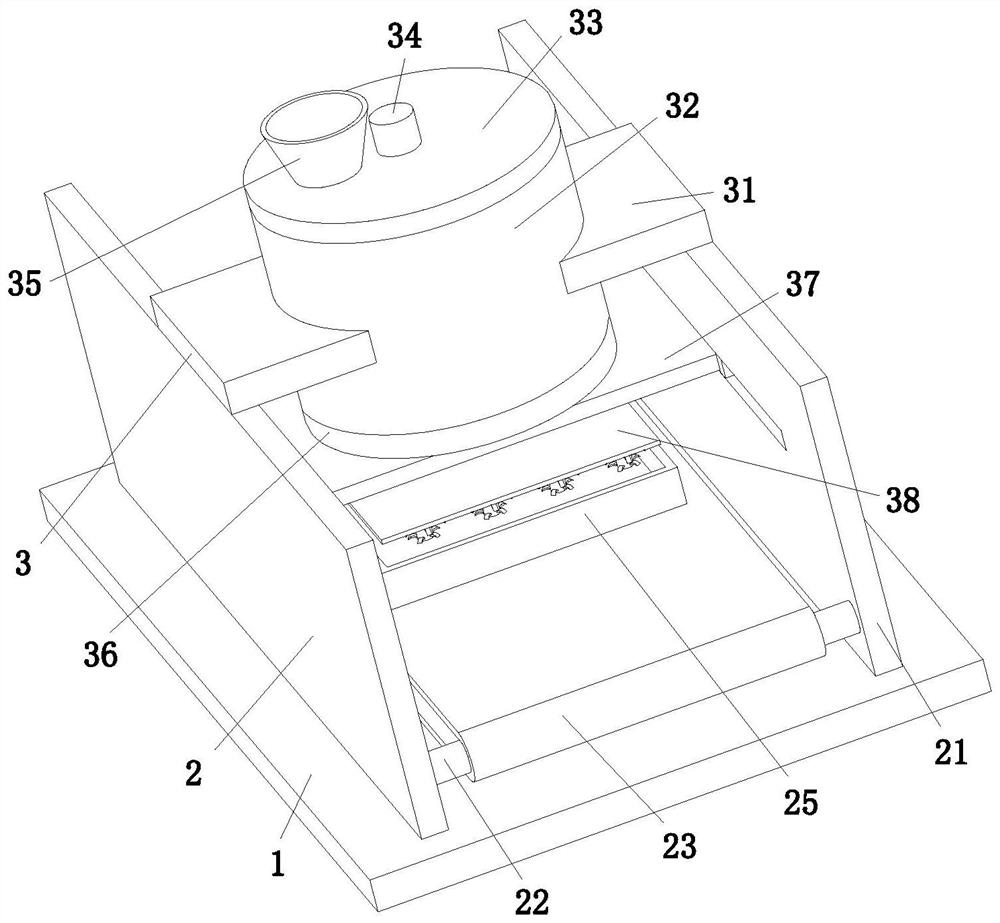

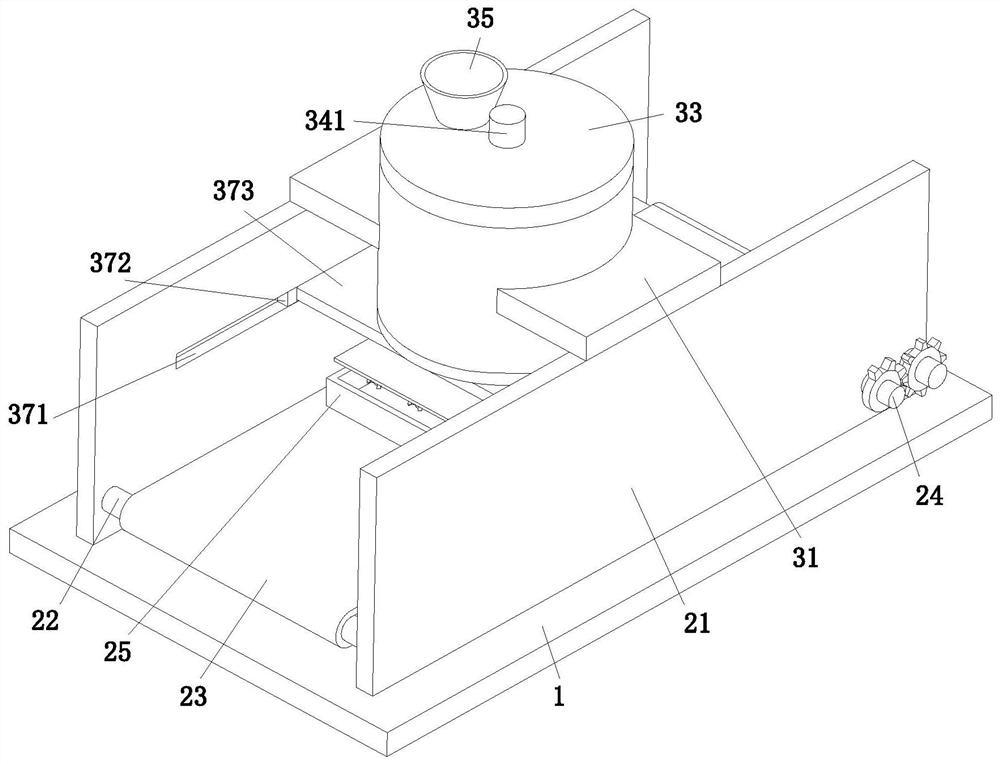

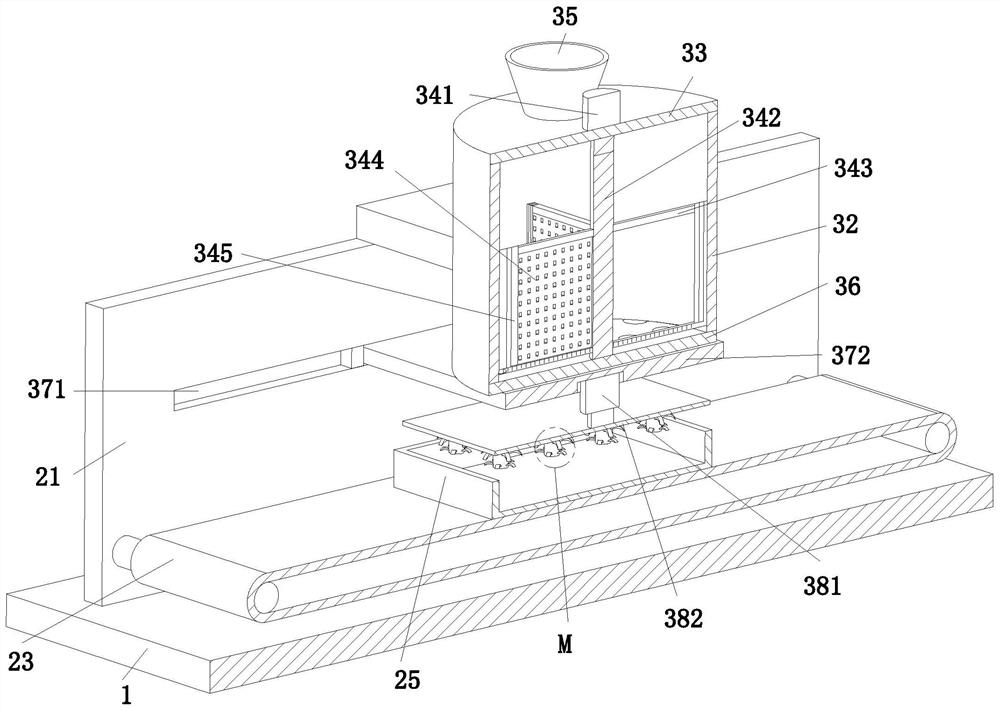

[0039] See figure 1 , figure 2 with Figure 4 A prefabricated concrete block molding machine production, including stage 1, the fixing device 2 and the mobile device 3, the table top 1 is provided with a fixing device 2, the mobile device 3 is provided on the fixing means;

[0040] See figure 1 withfigure 2 Said fixing means comprises a fixed structure 2 plate 21, rotation shaft 22, a transmission belt 23, the turret 24 and forming box 25, the end face of the right and left sides symmetrical on table 1 fixed plate 21 is attached to a fixed structure, two plate fixing structure is provided symmetrically with a rotary shaft 22 is rotated, the rotation shaft 22 is connected via two transmission belt 23 drives, wherein one end of a rotary shaft 22 through a fixing structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com