Woven bag double-sided film laminating equipment

A double-sided lamination and woven bag technology, applied in the field of machinery and equipment, can solve problems such as difficulty in film rolling, film offset, and impact on product quality, and achieve the effects of slowing down the contact area, facilitating processing and disassembly, and slowing down wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

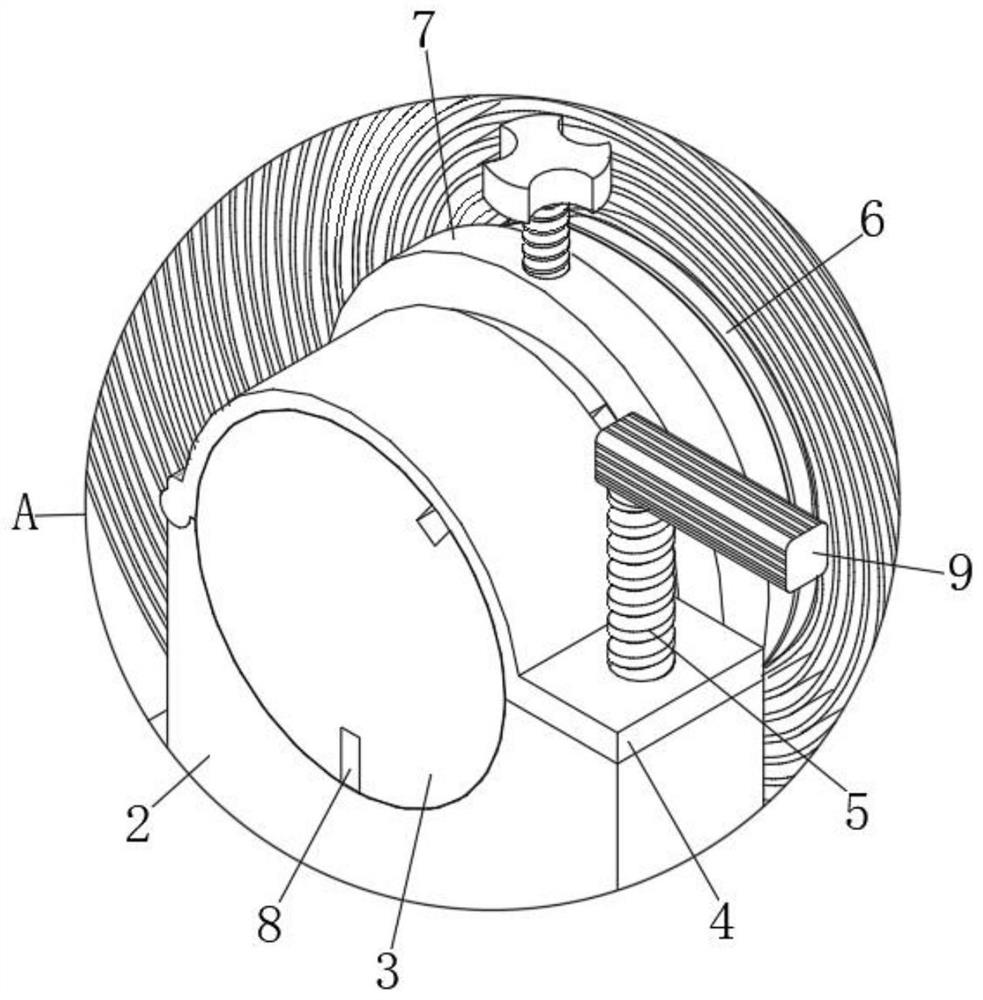

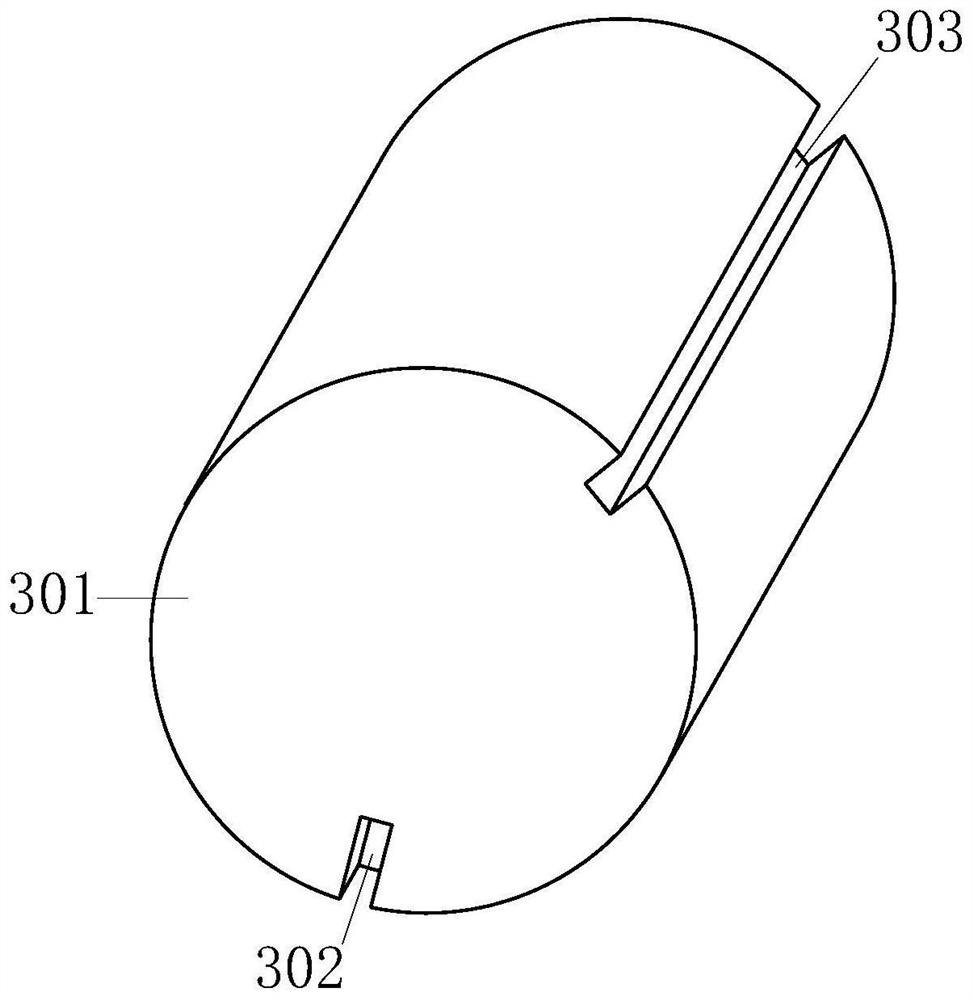

[0026] As a specific embodiment of the present invention, the installation shaft 3 includes a shaft body 301 disposed on the inner wall of the placement groove, and the surface of the shaft body 301 is respectively provided with a limiting groove 302 and a slide groove 303 .

[0027] The inner wall of the placement groove is fixedly connected with the limiting block 8 , and the limiting block 8 is adapted to the limiting groove 302 .

[0028] The top end of the screw rod 5 is fixedly connected with a handle 9, and the surface of the handle 9 is provided with anti-slip lines.

[0029] Concretely, when in use, align the limit groove 302 with the limit block 8, put the installation shaft 3 into the placement groove, then turn the clamp 4, and then turn the handle 9, the handle 9 drives the screw rod 5 to rotate and move downward to make The hoop 4 is fixed on the support base 2, and then the installation shaft 3 is fixed, preventing the installation shaft 3 from shaking during wo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap