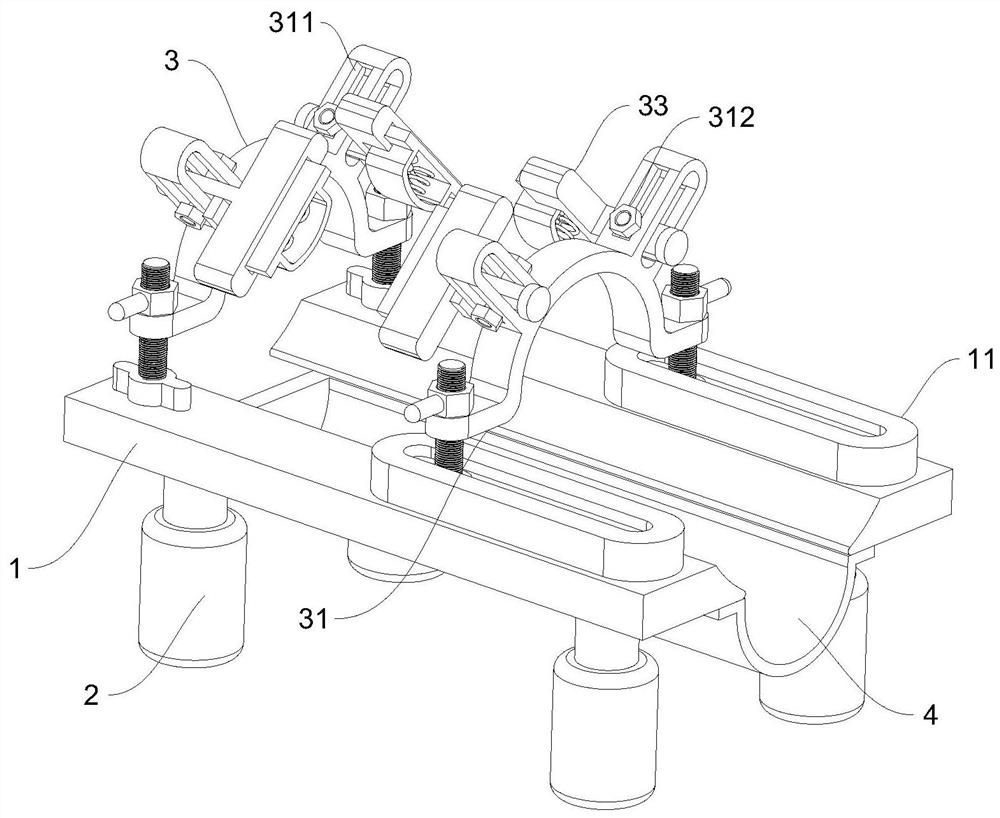

Fixing base for fixed motor maintenance

A technology of fixing base and fixing seat, applied in the manufacture of motor generators, electromechanical devices, electrical components, etc., can solve problems such as damage, affect the efficiency of motor maintenance, slow motor maintenance process, etc., and achieve the effect of enhancing applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

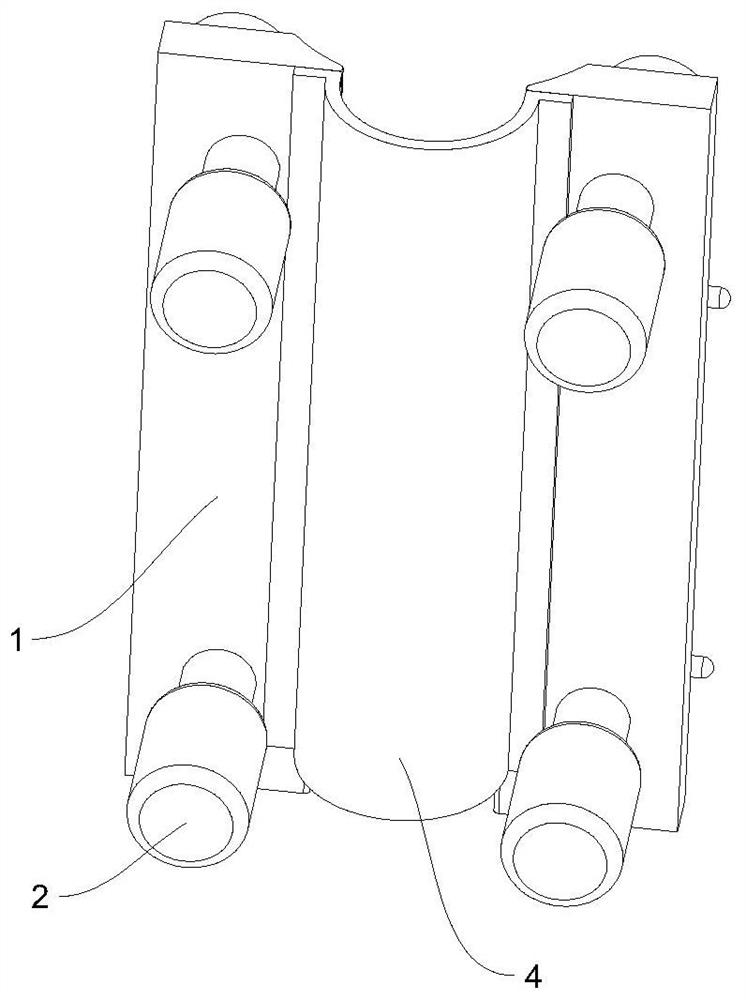

Examples

Embodiment approach

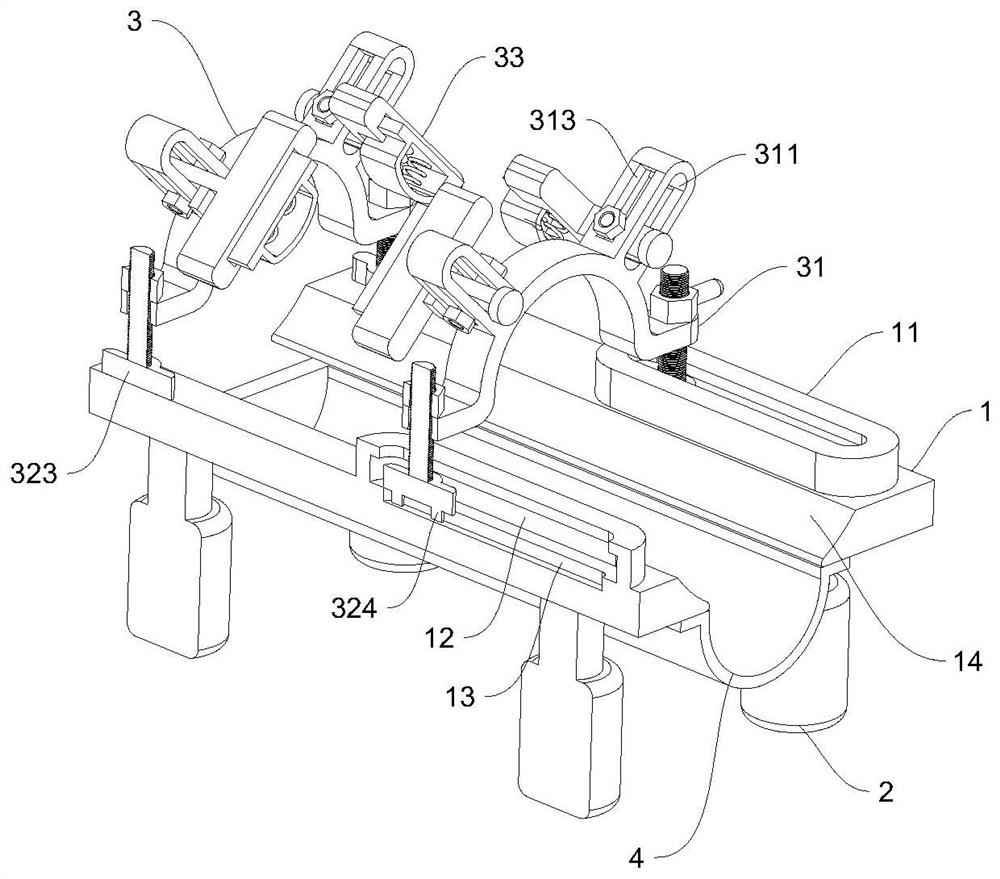

[0029] As an embodiment of the present invention, the lifting mechanism is composed of a bearing seat 321, a threaded rod 322 and a rotating handle 323; the bottom end of the threaded rod 322 is fixedly connected to the bearing seat 321; the rotating handle 323 is fixedly connected to At the top of the threaded rod 322 ; the threaded rod 322 is screwed to both ends of the support frame 31 , and the turning handle 323 is arranged above the support frame 31 .

[0030] During work, before the motor is fixed, it is necessary to manually observe the size of the motor. When facing a motor with a larger diameter, it is necessary to manually turn the handle 323 so that a relative screw rotation occurs between the threaded rod 322 and the support frame 31. The part of the support frame 31 that is screwed with the threaded rod 322 is provided with a ball nut, so when the threaded rod 322 rotates in situ, the support frame 31 can move vertically up and down relative to each other, thereby...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com