Continuous hydrolysis method of sulphaguanidine alkali precipitation solution

A technology for alkali precipitation and solution of sulfamidine, which is applied in the field of continuous hydrolysis of sulfamidine alkali precipitation solution, can solve the problems of expensive treatment cost, waste, utilization of substances that cannot be contained, and achieves the effect of being easy to handle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

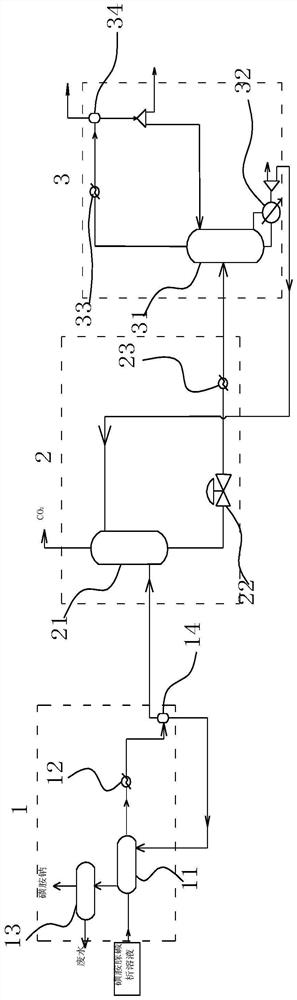

[0021] The present embodiment provides a continuous hydrolysis method of sulfamidine alkali analysis solution, adopting such as figure 1 The shown equipment is used for processing, and the equipment includes heat exchange reaction component 1, absorption component 2, rectification component 3 and so on.

[0022] The heat exchange reaction component 1 is used to heat the sulfamidine alkali solution for chemical reaction, and it includes a multi-stage heat exchanger 11 , a continuous tubular reactor 12 , a crystallizer 13 and a gas-liquid separator 14 . In the actual production process, the multistage heat exchanger 11 has a material inlet (ie, the sulfamidine alkali analysis solution inlet), a material outlet (ie, the sulfamidine alkali analysis solution outlet), a heat exchange medium inlet, and a heat exchange medium outlet; The sulfamidine alkali analysis solution is input into the heat exchanger 11 to be heated to 160-180° C. (the high-temperature liquid phase product in th...

Embodiment 2

[0033] This embodiment provides a continuous hydrolysis method of sulfamidine alkali analysis solution, which is basically the same as that in Example 1, except that in step (a), the continuous tubular reactor 12 is used under the conditions of 190 ° C and 16 barg After 6 hours of reaction, the yield of ammonia water was 92%, and the yield of sodium sulfonamide was 95%.

Embodiment 3

[0035] This embodiment provides a continuous hydrolysis method of sulfamidine alkali analysis solution, which is basically the same as that in Example 1, except that in step (a), the continuous tubular reactor 12 is used under the conditions of 210 ° C and 25 barg After reacting for 3 hours, the yield of ammonia water was 96%; the yield of sodium sulfonamide was 96%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com