Organic/inorganic nano-composite gel plugging agent and oil-based drilling fluid

An oil-based drilling fluid and inorganic nanotechnology, applied in the field of oil-based drilling fluid, can solve problems such as wellbore instability and achieve good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

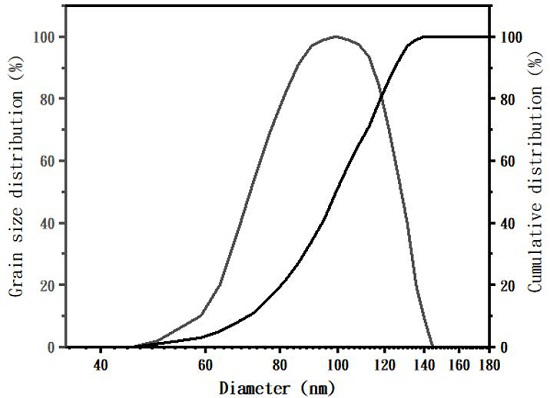

[0028] Preparation of poly(butyl oleate-co-N-isopropylacrylamide-co-stilbene)-zirconia nanocomposite gel: Take an appropriate amount of nano-zirconia powder and dry it at 60°C for 6 hours, then put it in a desiccator spare. Weigh 2.62g of dried nano zirconia sample, pour it into 15ml of toluene, and ultrasonically disperse for 40min to disperse the nano zirconia in the solution. Continue to add 10ml of 10% silane coupling agent KH-570 to it, and sonicate for 10min. Then pour the resulting liquid into a flask and react at 70°C for 30min. Cool to room temperature, centrifuge for 20 minutes, and then ultrasonically disperse for 10 minutes. Suction filtration and washing to obtain modified nano zirconia. The modified product of nano-zirconia was dispersed with 90ml of ethanol / water dispersion, 6g of butyl oleate, 2.4g of N-isopropylacrylamide and 2.4g of stilbene were added, and 0.1g of crosslinking agent divinylbenzene was added. Keep stirring quickly, and pass nitrogen gas a...

Embodiment 2

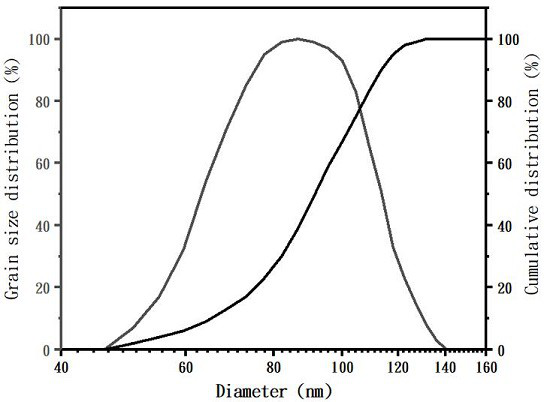

[0030] Preparation of poly(butyl oleate-co-N-isopropylacrylamide-co-stilbene)-zirconia nanocomposite gel: Take an appropriate amount of nano-zirconia powder and dry it at 70°C for 7 hours, then put it in a desiccator spare. Weigh 3.54g of dried nano zirconia sample, pour it into 20ml of toluene, and ultrasonically disperse for 40min to disperse the nano zirconia in the solution. Continue to add 15ml of 10% silane coupling agent KH-570 to it, and sonicate for 20min. Then pour the resulting liquid into a flask and react at 80°C for 40min. Cool to room temperature, centrifuge for 30 minutes, and then ultrasonically disperse for 20 minutes. Suction filtration and washing to obtain modified nano zirconia. Disperse the modified product of nano-zirconia with 110ml ethanol / water dispersion liquid, add 6.5g butyl oleate, 3.25g N-isopropylacrylamide and 4.87g stilbene, crosslinking agent divinylbenzene 0.44g , maintain rapid stirring, and pass nitrogen gas under the condition of 60°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com