Prefabricated bay window and connecting method

A bay window and prefabricated panel technology, which is applied in the direction of construction and building construction, can solve the problems of long construction period, low efficiency, inaccurate installation position, etc., and achieve the effect of short construction period, high efficiency, and easy connection and fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

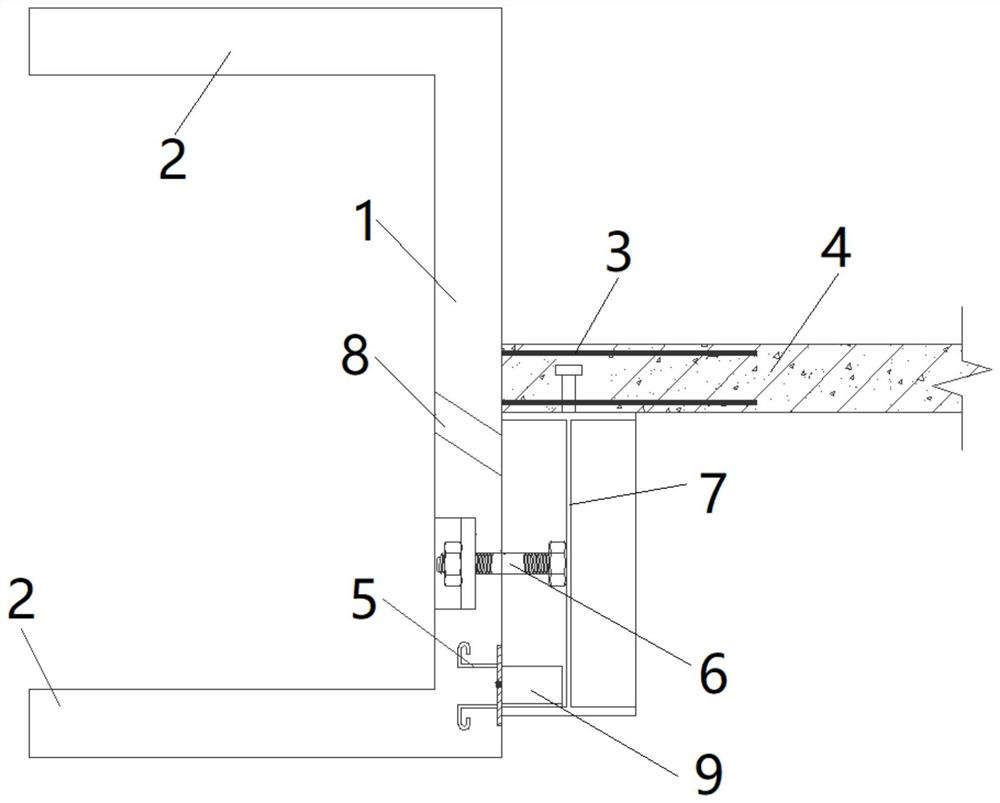

[0035] The prefabricated bay window provided in this embodiment includes: two prefabricated components arranged at intervals up and down, and a bay window space is formed between the two prefabricated components.

[0036] Such as figure 1 As shown, the prefabricated components include: a first prefabricated slab 1 and a second prefabricated slab 2 perpendicular to each other, the second prefabricated slab 2 has two parallel arrangements, and the two second prefabricated slabs 2 are spaced up and down Formed on the same side of the first prefabricated panel 1 . A plurality of first embedded parts 3 are pre-embedded in the middle of the first prefabricated panel 1, where the first embedded parts 3 are anchoring steel bars; the first embedded parts 3 have vertically protruding The protruding part on the outer surface is used to be embedded in the interior of the floor slab 4 . The first prefabricated panel 1 has a second embedded part 5 embedded along its width direction, and t...

Embodiment 2

[0040] The connection method of the prefabricated bay window provided in this embodiment includes the following steps:

[0041] S1: Before the concrete pouring of floor 4, hoist the prefabricated components of the upper floor and the prefabricated components of the lower floor to the corresponding installation positions respectively;

[0042] S2: The first embedded part 3 extends into the floor 4, and the positioning part 6 on the steel beam 7 penetrates into the positioning hole of the second prefabricated slab 2 to realize the preliminary positioning of the second prefabricated slab 2, the floor 4 and the steel beam 7 connect;

[0043] S3: between the second embedded part 5 and the steel beam 7 of the floor 4, welding is performed through the connecting block 9;

[0044] S4: pouring concrete into the grouting hole 8 to realize the pouring connection between the first prefabricated slab 1 and the steel beam 7;

[0045] S5: Co-casting the floor slab 4, the steel beam 7 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com