Pure oil-free high-speed compressor based on air suspension bearing

An air suspension and compressor technology, applied in the field of compressors, can solve the problems affecting the use efficiency of compressed air, compressed air pollution, and large motor vibration, so as to improve safety and stability, improve operating efficiency, and improve service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

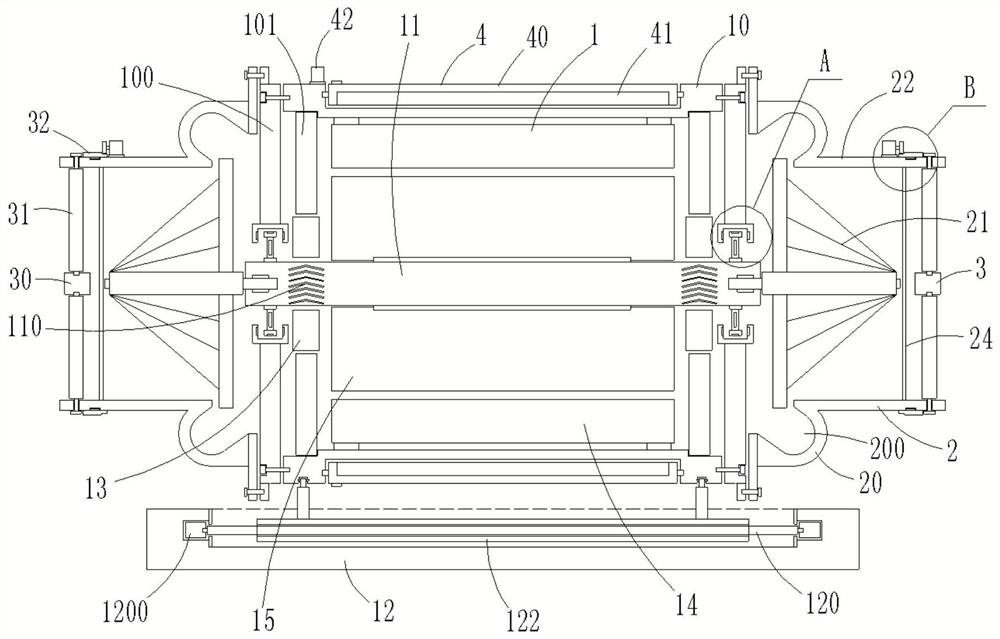

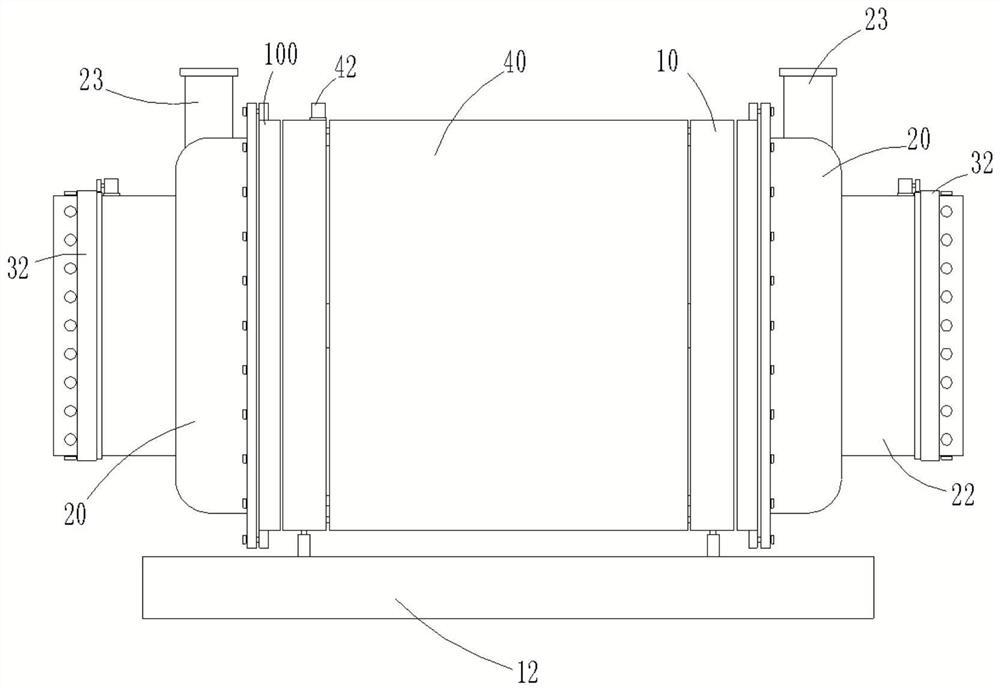

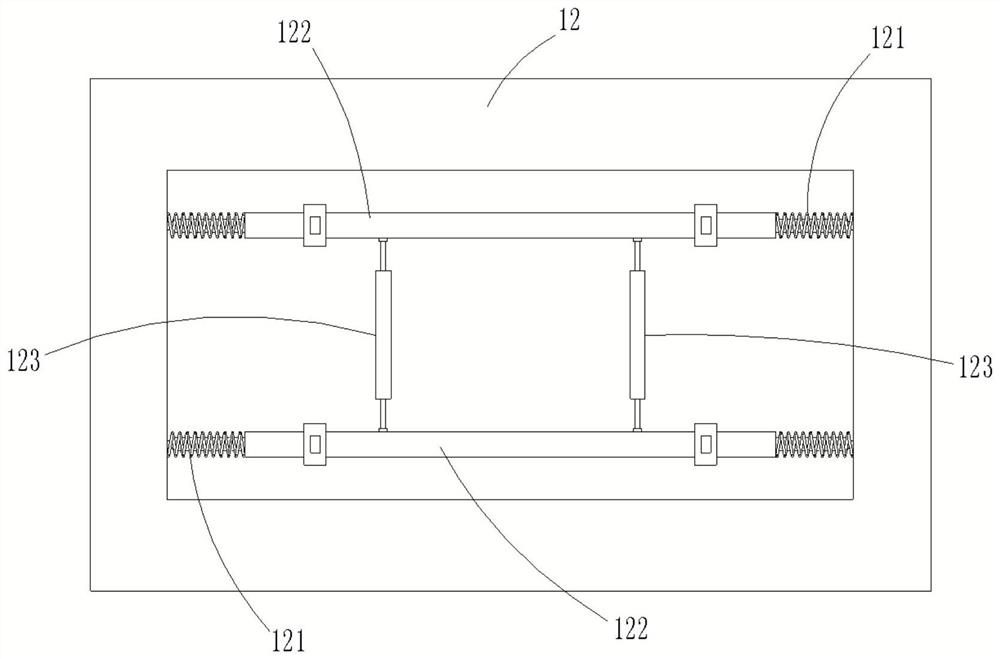

[0044] Embodiment 2: as figure 1 , 2 , 3, 4, 6, and 7 show a pure oil-free high-speed compressor based on air suspension bearings, including a motor 1, a turbine 2, a pressure regulating assembly 3, a cooling assembly 4 and a controller; the motor 1 includes a motor housing 10 and the main shaft 11, the motor casing 10 is hollowed out, the lower end of the motor casing 10 is movably connected with a base 12, the upper end of the base 12 is provided with a notch, and two sliding rods 120 are horizontally clamped inside the notch 12, and the two ends of the two sliding rods 120 The rollers 1200 are slidably connected to the inner wall of the notch, and each sliding rod 120 is sheathed with two damping springs 121 and a sliding sleeve 122, the sliding sleeve 122 is located between the two damping springs 121, and the two sliding sleeves 122 The motor housing 10 is movably connected with the two sliding sleeves 122 through the connecting plate. By setting the sliding rod 120 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com