Boiler liquid level meter based on ultrasonic ranging

An ultrasonic and liquid level gauge technology, applied in the field of boiler liquid level gauges, can solve problems such as affecting boiler temperature, hidden dangers of glass-type liquid level gauges, and inaccurate liquid level reading, and achieves reduced interference, high intelligence, and increased The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

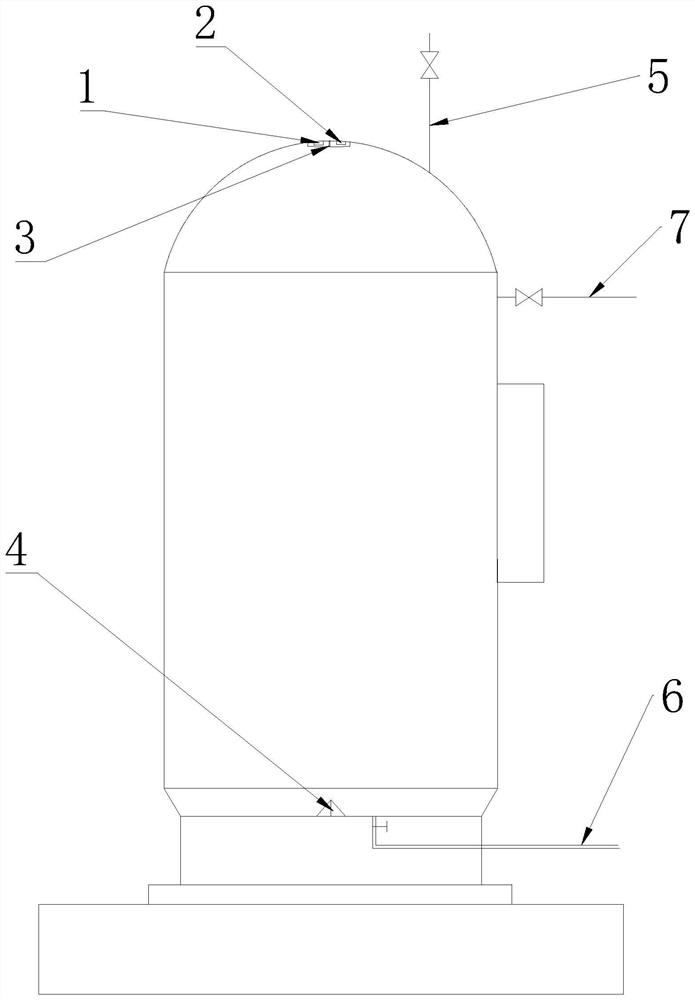

[0028] Such as figure 1 A boiler liquid level gauge based on ultrasonic ranging is shown, including a boiler body, a steam valve 5 arranged on the top of the boiler body, a blowdown valve 6 arranged at the bottom of the boiler body, and a water supply valve 7 arranged on the side of the boiler , the ultrasonic distance measuring module arranged on the top of the boiler liner, the anti-interference module 4 arranged on the bottom surface of the boiler liner, the boiler is also provided with a main control module, and the main control module is electrically connected to the ultrasonic distance measurement module.

[0029] The anti-jamming module 4 is an ultrasonic absorbing module, the ultrasonic absorbing module is a diamond-shaped protrusion, and the ultrasonic absorbing module is made of porous silicon carbide absorbing material. Porous sound absorption relies on friction between air and pores to convert sound energy into heat energy. The ultrasonic absorption module absorbs ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com