Light homogenizing type processing technology for color steel plate

A processing technology and light uniform technology, applied in the direction of pretreatment surface, coating, surface coating liquid device, etc., to achieve the effect of improving the uniformity and improving the quality of the paint film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

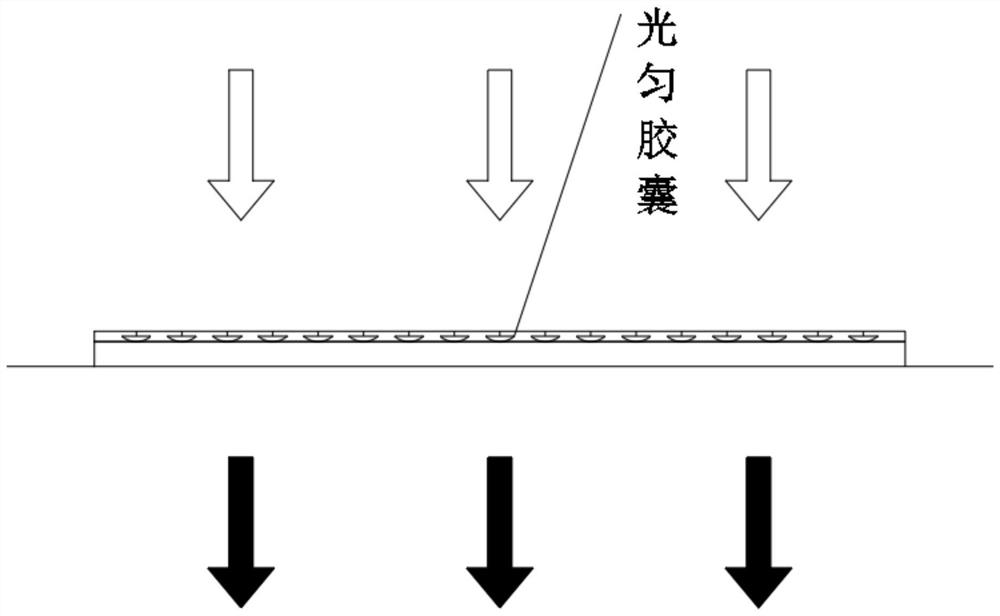

[0047] see figure 1 , a color steel plate light uniform processing technology, comprising the following steps:

[0048] S1. Clean the raw steel plate with a degreasing solution, then rinse the surface of the raw steel plate with clean water and dry until there is no moisture;

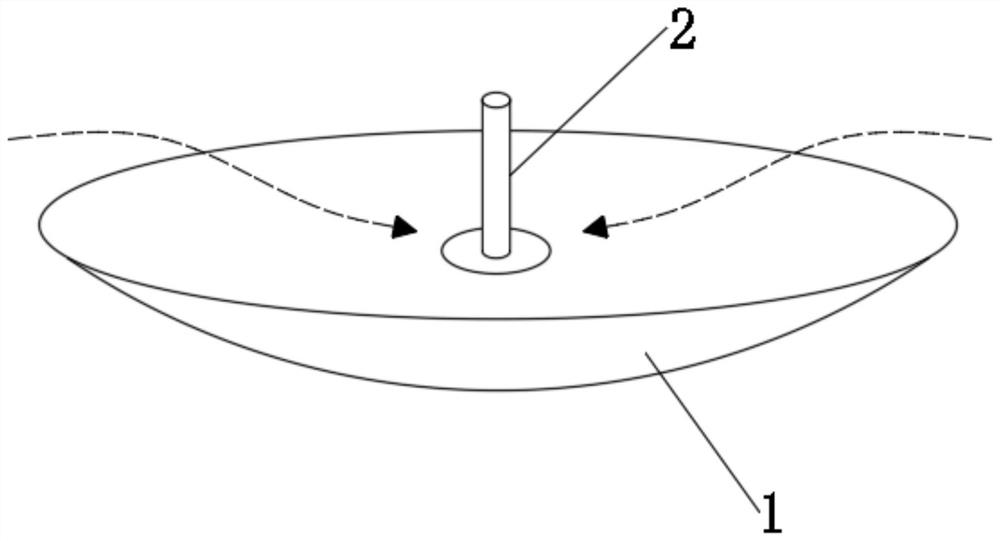

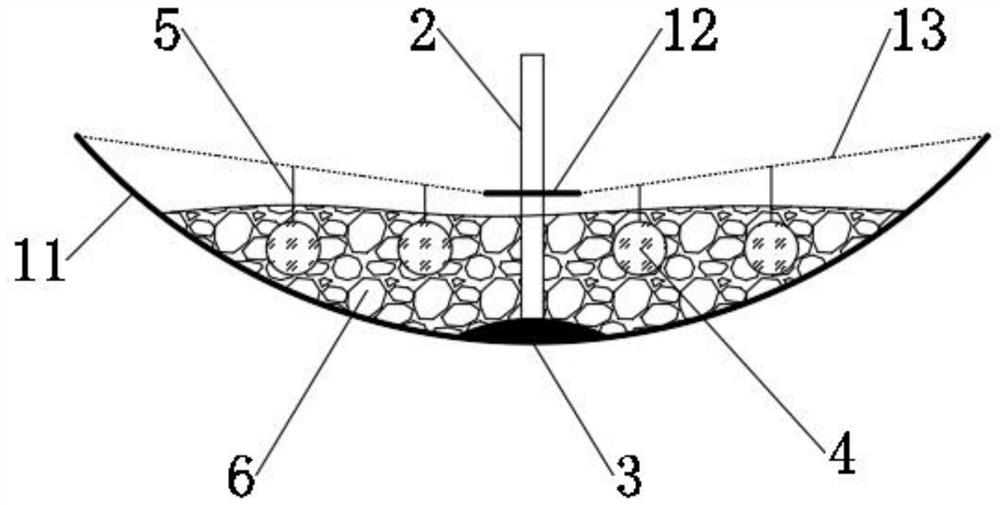

[0049] S2. Corona treatment is performed on the raw steel plate to form multiple pits on the surface, and a plurality of smooth capsules are evenly placed on the surface of the raw steel plate;

[0050] S3. Apply a magnetic field on the back of the raw steel plate to adsorb and position the light-uniform capsule, and then prepare the paint and spray it on the surface of the raw steel plate;

[0051] S4. The paint is irradiated with strong light, and the light-uniform capsule independently perceives the sunken area of the paint, and expands to replenish the material to ensure that the thickness of the paint is uniform;

[0052] S5. After the paint is cured, the surface of the paint film is washed wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com