Automobile air conditioner ventilation device and use method thereof

A technology for ventilation devices and automobile air conditioners, which is applied in the direction of separation methods, electrostatic cleaning, air treatment equipment, etc., can solve the problems of difficult cleaning, increase the weight and installation space of ventilation and ventilation devices, and poor electrostatic dust removal effect, etc., and achieve improvement The effect of the filter effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

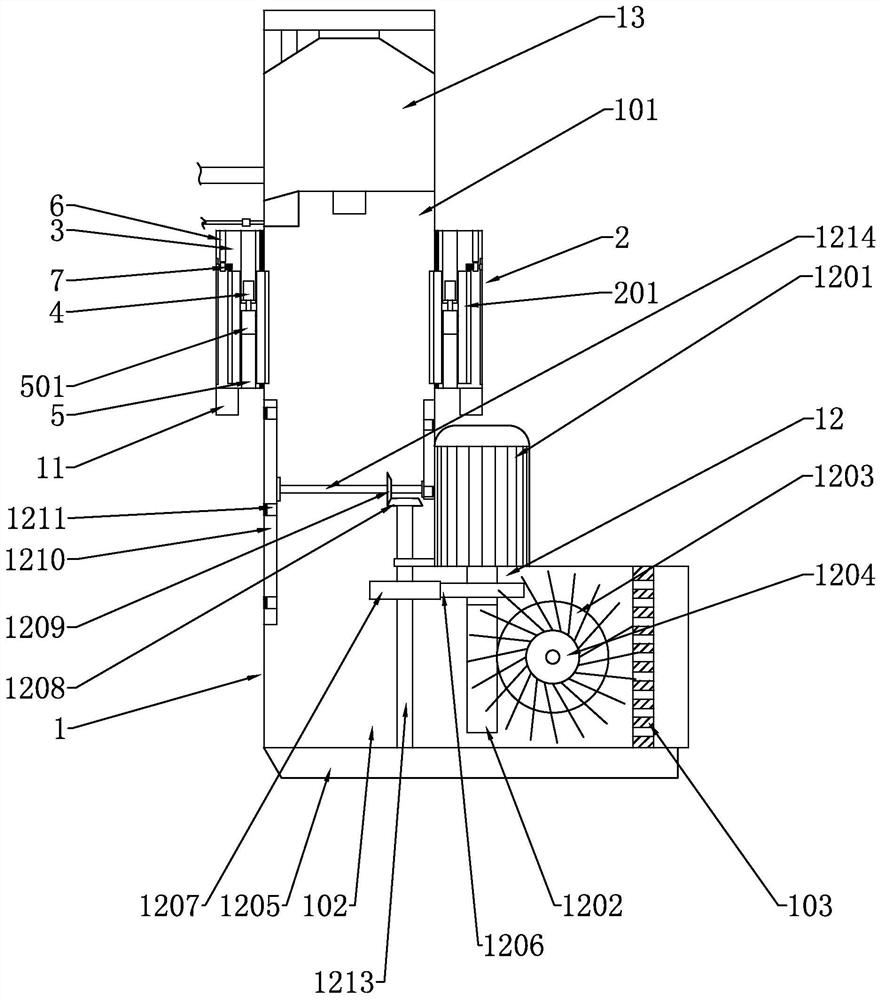

[0068] Such as Figure 1 to Figure 5 As shown, the embodiment of the present application provides an automobile air-conditioning ventilation device, which is characterized in that it includes:

[0069] Ventilation pipe 1, said ventilation pipe 1 comprises a vertical pipe 101 and a horizontal pipe 102, said horizontal pipe 102 is provided with an entrance, and said entrance is provided with a mesh plate 103;

[0070] An electrostatic precipitator 2, the electrostatic precipitator 2 includes an electrode plate 201;

[0071] Dust removal box 3;

[0072] The first rotating motor 4;

[0073] A support column 5, the upper end of the support column 5 is rotatably provided with a turning block 501;

[0074] The first telescopic cylinder 6;

[0075] Brush 7;

[0076] Wherein, the electrostatic precipitator 2 is symmetrically arranged on the inner walls of both sides of the vertical pipe 101, the dust removal box 3 is symmetrically arranged on the outer walls of both sides of the v...

Embodiment 2

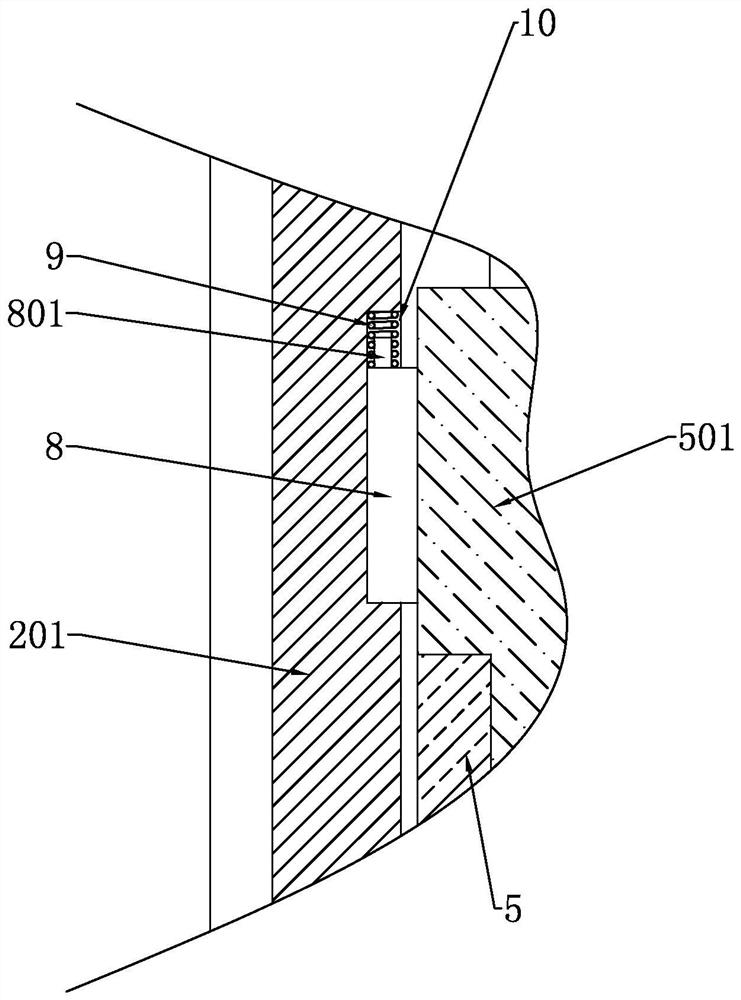

[0079] In this embodiment, in addition to including the structural features of the foregoing embodiments, it further includes:

[0080] A connection block 8, the upper surface of the connection block 8 is provided with a contact 801;

[0081] spring 9;

[0082] connection slot 10;

[0083] controller;

[0084] The first dust collecting box 11;

[0085] Wherein, the connecting block 8 is fixedly arranged on the side wall of the rotating block 501, the connecting groove 10 is arranged on the side wall of the opposite side of the electrode plate 201 and the rotating block 501, and the connecting block 8 is slidably arranged in the connecting groove In 10, the spring 9 is sleeved on the contact 801, one end of the spring 9 is connected to the upper surface of the connection block 8, and the other end is connected to the upper inner wall of the connection groove 10, and the contact 801 is connected to the controller electrical connected, the controller is electrically connected...

Embodiment 3

[0088] In this embodiment, in addition to including the structural features of the foregoing embodiments, it further includes:

[0089] Pipe wall dust removal mechanism 12;

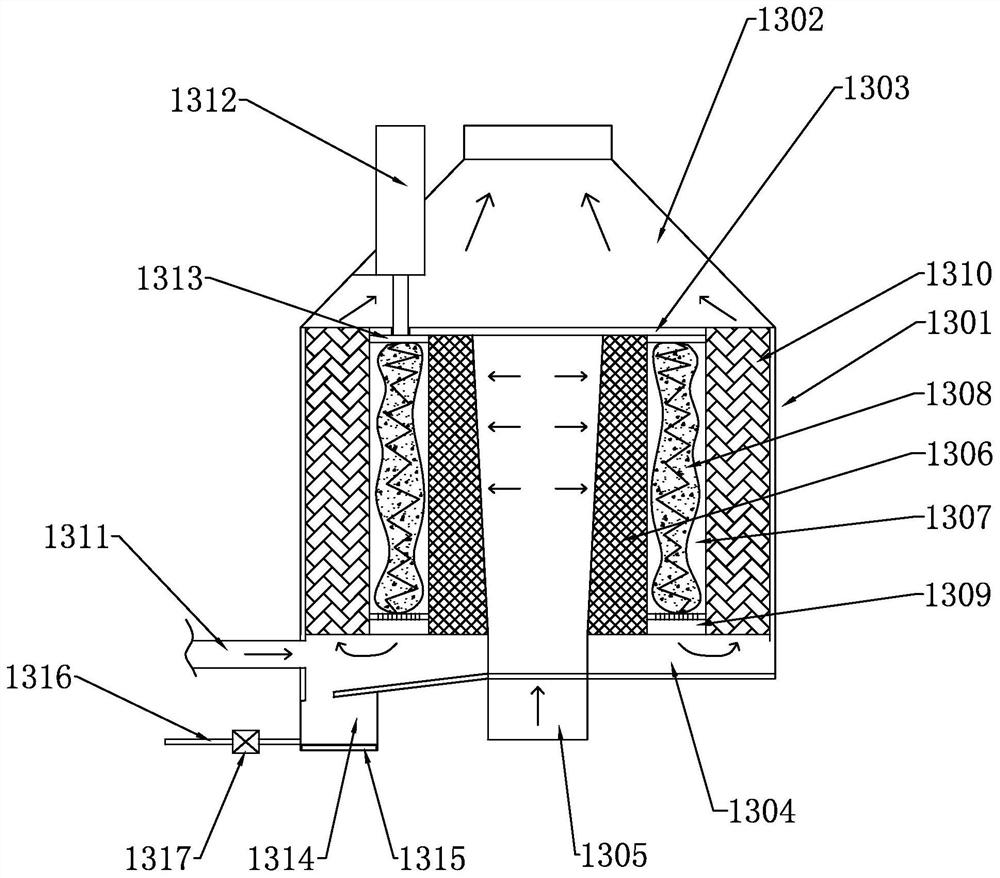

[0090] filter mechanism 13;

[0091] Wherein, the pipe wall dust removal mechanism 12 is arranged in the ventilation pipe 1 and is located between the electrostatic dust removal mechanism 2 and the entrance of the ventilation pipe 1, and the pipe wall dust removal mechanism 12 is used to clean up the dust attached to the wall of the ventilation pipe 1, so The filter mechanism 13 is arranged in the vertical pipe 101 of the ventilation pipe 1 and above the electrostatic precipitator 2, and the filter mechanism 13 is used to further filter the air.

[0092] In the embodiment of the present application, the above-mentioned automobile air-conditioning ventilation device is adopted. During use, the pipe wall dust removal mechanism can clean up the dust on the pipe wall between the entrance of the horizontal pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com