Container ship cargo hold channel structure

A channel structure, container ship technology, applied in the direction of part of the hull, hull, ship construction, etc., can solve the problems of difficult maintenance and containment, the bilge water cannot be discharged smoothly, etc., to improve damage stability and ship safety. , to avoid corrosion, to eliminate the effect of unfavorable factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment one (comparative example):

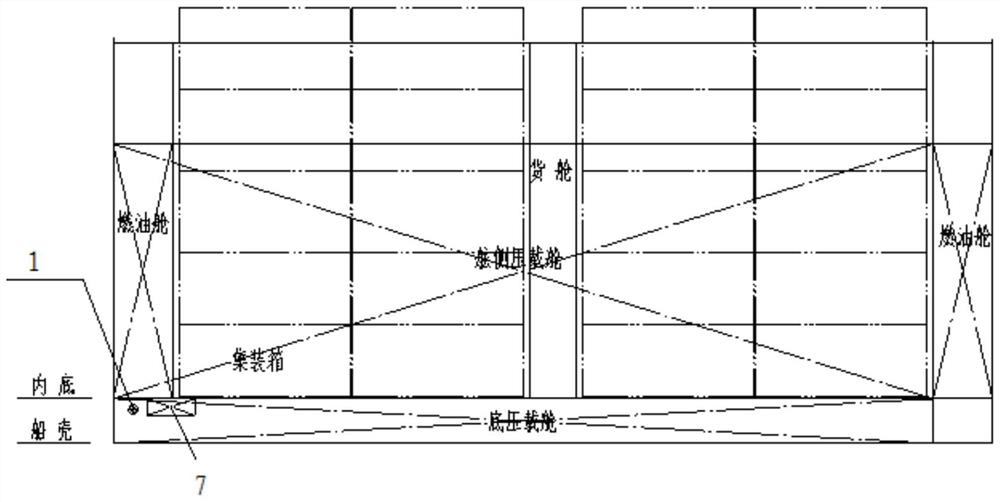

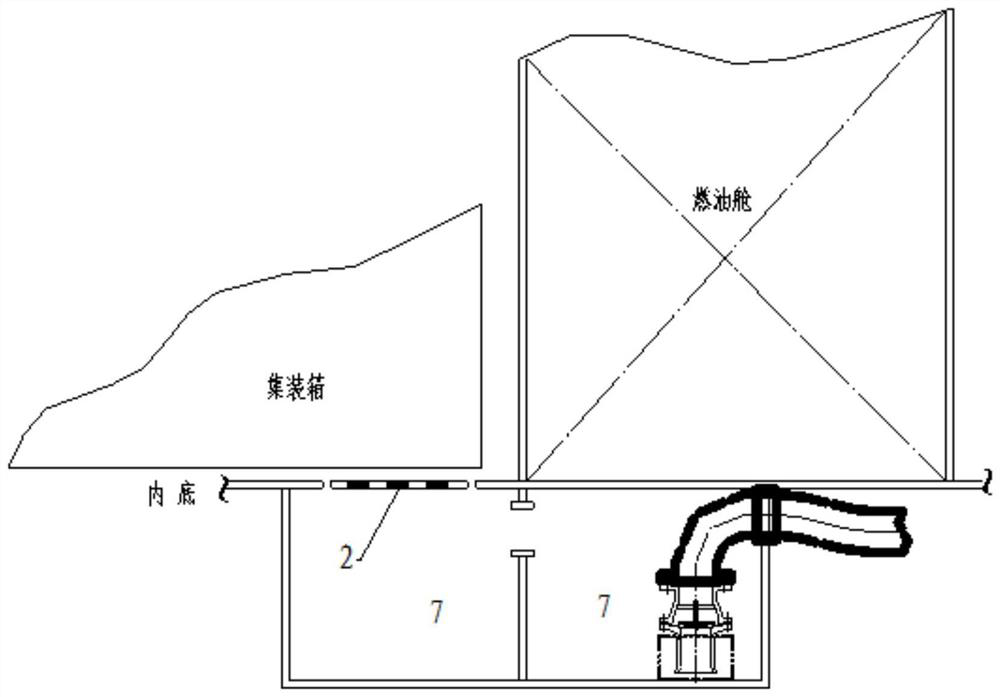

[0026] The transverse bulkhead adjacent to the cargo tank of the existing container fuel tank extends upward from the inner bottom to the main deck. A part of the sewage well is located in the cargo tank, and a part is located below the fuel tank and is covered by the fuel tank. If there are containers in the hold, the container will cover the sewage well in the hold area. Such as figure 1 , 2 shown.

[0027] Since the ballast branch pipe of the side ballast tank is connected to the ballast main pipe located in the inner bottom pipe of the ship, it needs to pass through the bottom ballast tank horizontally, such as image 3 shown.

[0028] Conventional arrangements do not provide this access for the crew, and the portion of the mesh panel where the bilge well has leaking holes is covered by the container, while the remaining structure of the bilge well is covered above by the fuel tank. Two sewage wells are usually arranged h...

Embodiment 2

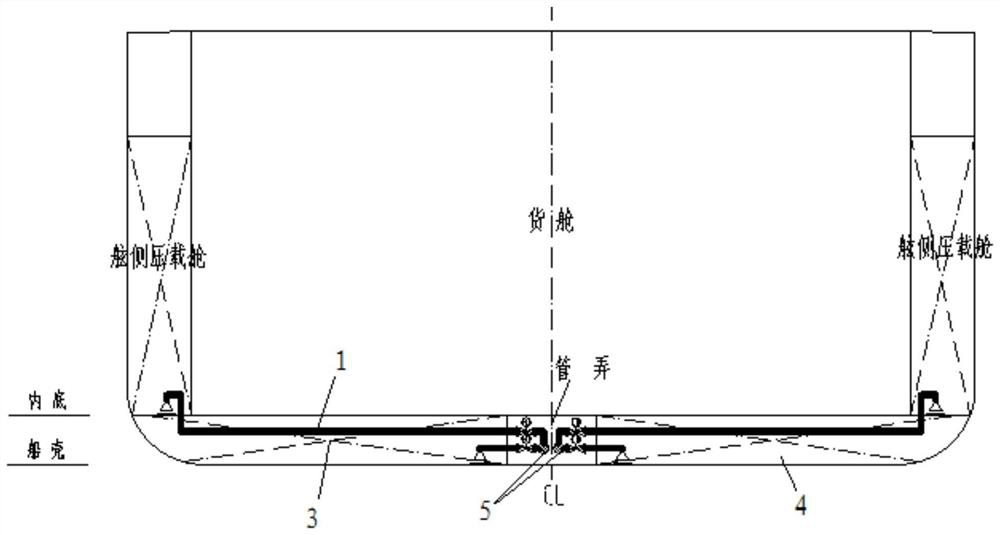

[0031] see Figure 4-6 , a container ship cargo hold channel structure, the fuel tank is arranged adjacent to the front and rear directions of the cargo tank, and a sewage well 7 is respectively provided on the lateral sides in the inner bottom area of the hull below the junction of the fuel tank and the cargo tank. The edge of the bottom side is sunken inward, and an inspection passage 8 is formed along the transverse direction of the hull, and the inspection passage 8 is located directly above the sewage wells 7 on both sides of the hull laterally; The inspection passage 8 is arranged along the inspection passage 8 and finally accesses the side ballast tank.

[0032] The width, depth and height of the maintenance access can be adjusted according to the actual layout and regulatory requirements, and the direction and quantity of side ballast branch pipes can be adjusted according to the actual compartment division.

[0033] see Figure 5 , The bottom of the maintenance ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com