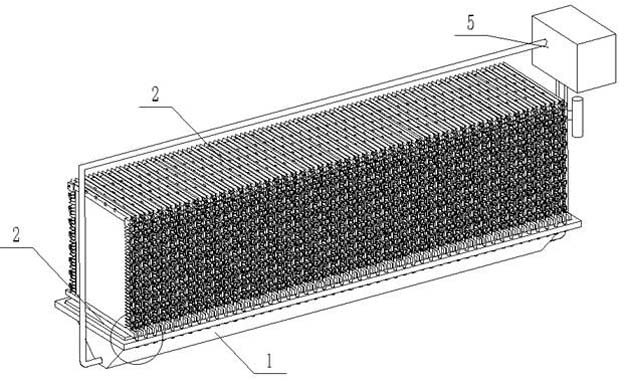

Assembled electrolytic cell diaphragm frame

An electrolytic cell and assembled technology, which is applied in the direction of diaphragm, electrolytic process, electrolytic components, etc., can solve the problems of troublesome maintenance and high maintenance cost, and achieve the effects of low maintenance cost, compact connection, and convenient installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

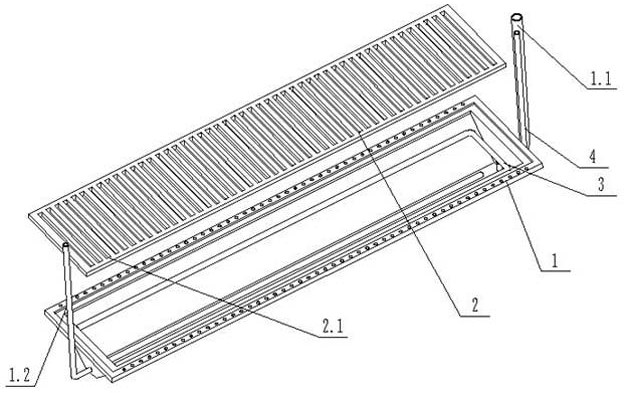

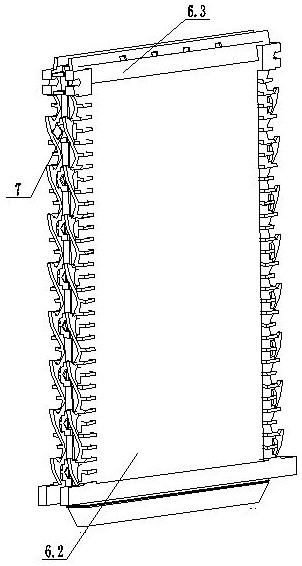

[0029] Embodiment 1: as figure 1 , 2 , 3, 4, 5, 6, and 7, an assembled electrolyzer diaphragm frame, including a bottom tank 1 with an open top, a bottom plate 2 is provided on the top of the bottom tank 1, and several The aeration pipe 3, the outside of the bottom tank 1 is provided with the aeration main pipe 4 connected with the aeration pipe 3, the cross section of the bottom tank 1 is V-shaped, the bottom tank 1 is provided with a suction main pipe 1.1 and a return main pipe 1.2, and a suction main pipe 1.1 It is connected with the return main pipe 1.2 through a filter 5 located outside the bottom tank 1. There are several sockets 2.1 arranged in parallel on the bottom plate 2. A diaphragm frame 6 is inserted into each socket 1.3, and the diaphragm frame 6 is movably connected with the bottom tank 1. And the connection is sealed, the diaphragm frame 6 includes a square inner core frame 6.1, the top plate and the bottom plate of the square inner core frame 6.1 are provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com