Stable and firm edge sealing device for producing and processing medical non-woven fabric

An edge banding device and non-woven fabric technology, which is applied in the medical field, can solve the problems of poor firmness of elastic bandages, inability of elastic bandages, and increased number of bacterial growth in elastic bandages, so as to improve stability and firmness and reduce bacterial growth. Quantity, the effect of reducing the risk of infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

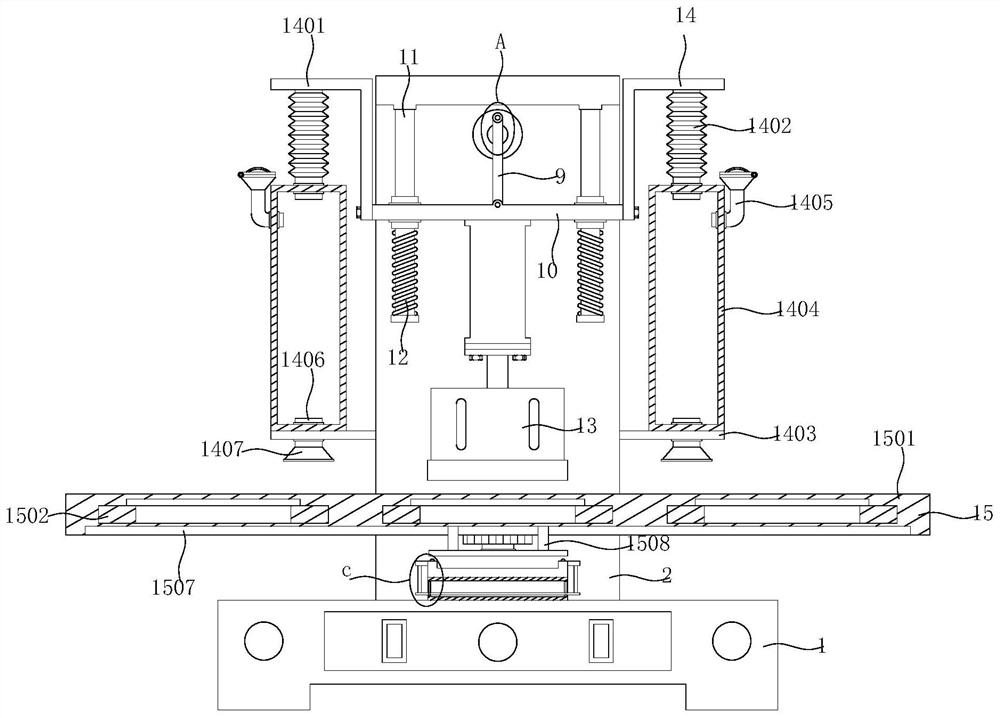

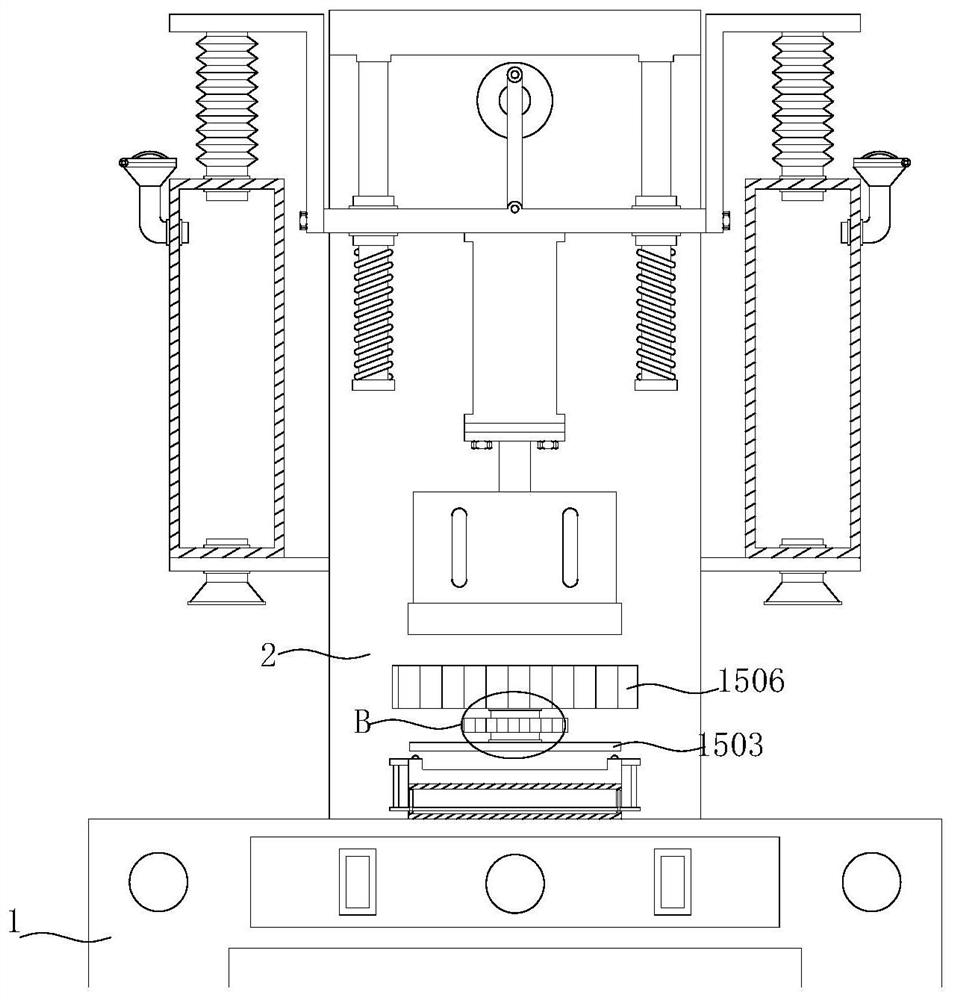

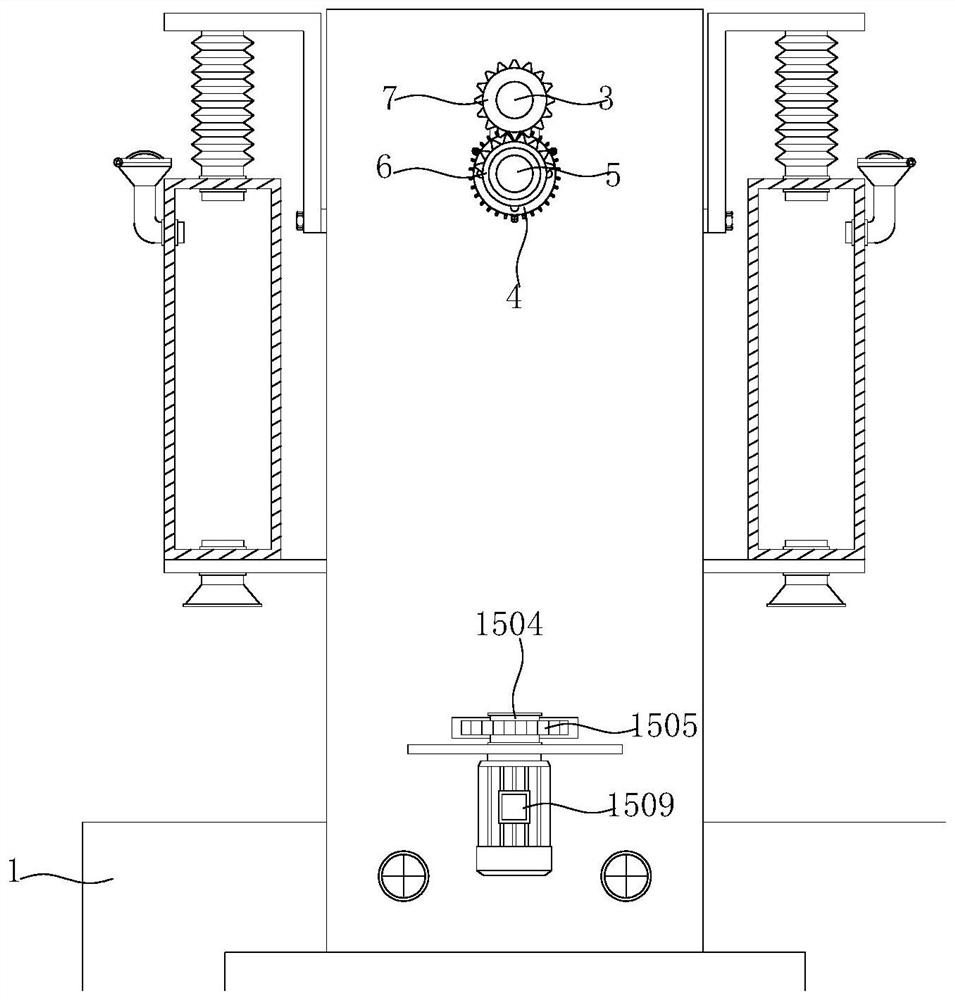

[0028] see Figure 1-8, the present invention provides a technical solution: a stable and firm edge banding device for the production and processing of medical non-woven fabrics, including an ultrasonic generator 1, a bow-shaped plate 2 is fixedly installed on the rear outer surface of the ultrasonic generator 1, and the bow-shaped The rear outer surface of the plate 2 is rotated with a long rotating rod 3, and the rear outer surface of the arched plate 2 is fixed with a DC motor 4. The output shaft of the DC motor 4 is fixedly connected with a short rotating rod 5 through a coupling, and the long rotating rod The fixed sleeve on the rod 3 is provided with a vertical tooth gear 7, the fixed sleeve on the short rotating rod 5 is provided with an incomplete gear 6, the incomplete gear 6 and the short rotating rod 5 mesh with each other, and one end of the long rotating rod 3 runs through the bow plate 2 and is fixed Connected with a turntable 8, the outer surface of the front si...

Embodiment 2

[0032] see Figure 1-8 , on the basis of Embodiment 1, the disinfection mechanism 14 includes an L-shaped plate 1401, an air pump 1402, a support plate 1403, a water storage tank 1404, an elbow 1405, a water pipe 1406 and a spray head 1407, and the outer walls of both sides of the horizontal plate 10 pass through An L-shaped plate 1401 is fixedly installed by bolts, and support plates 1403 are fixedly installed on the outer walls of both sides of the bow-shaped plate 2, and a water storage tank 1404 is fixedly installed on the top outer surface of the support plate 1403, and an air pump is fixedly connected to the top outer surface of the water storage tank 1404 1402 and the other end of the air pump 1402 extends to the inside of the water storage tank 1404, one end of the air pump 1402 is fixedly connected to the bottom outer surface of the L-shaped plate 1401, and an elbow 1405 is fixedly connected to the outer wall of the water storage tank 1404 and the elbow 1405 One end e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com