Fabricated double-layer corrugated steel plate composite shear wall and splicing method thereof

A corrugated steel plate and shear wall technology, applied in protective buildings/shelters, building types, buildings, etc., can solve the problems of low construction efficiency, inconvenient construction, and complicated operation, and achieve enhanced connection strength and construction efficiency. High, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

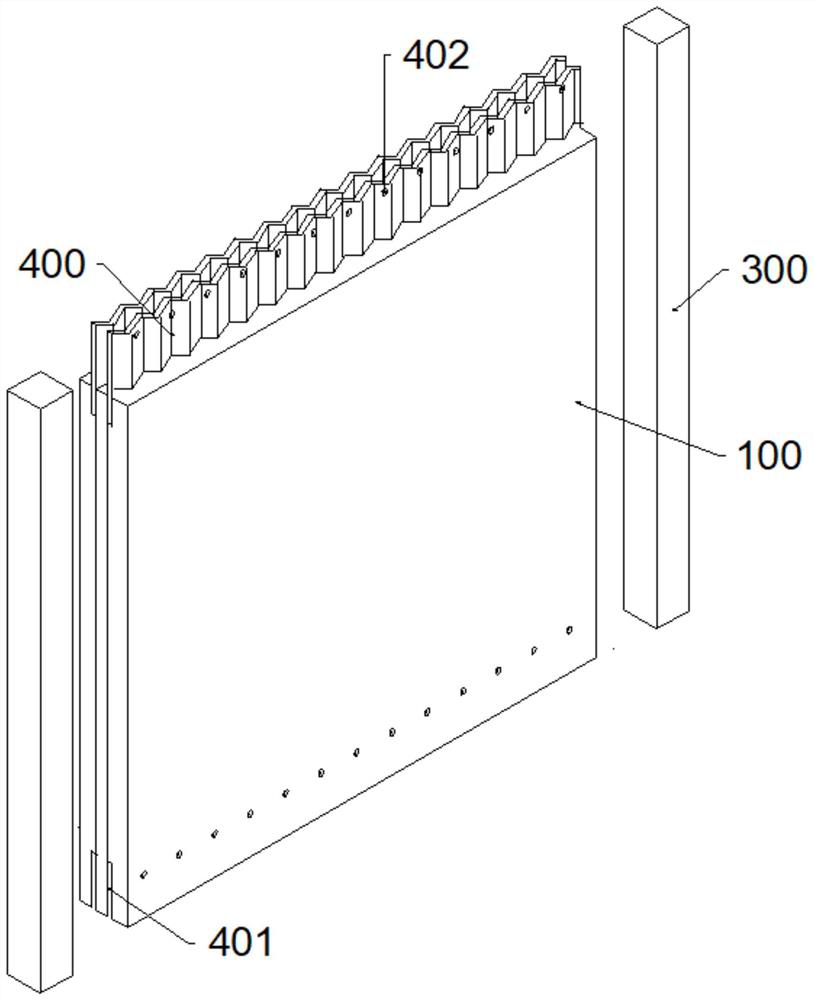

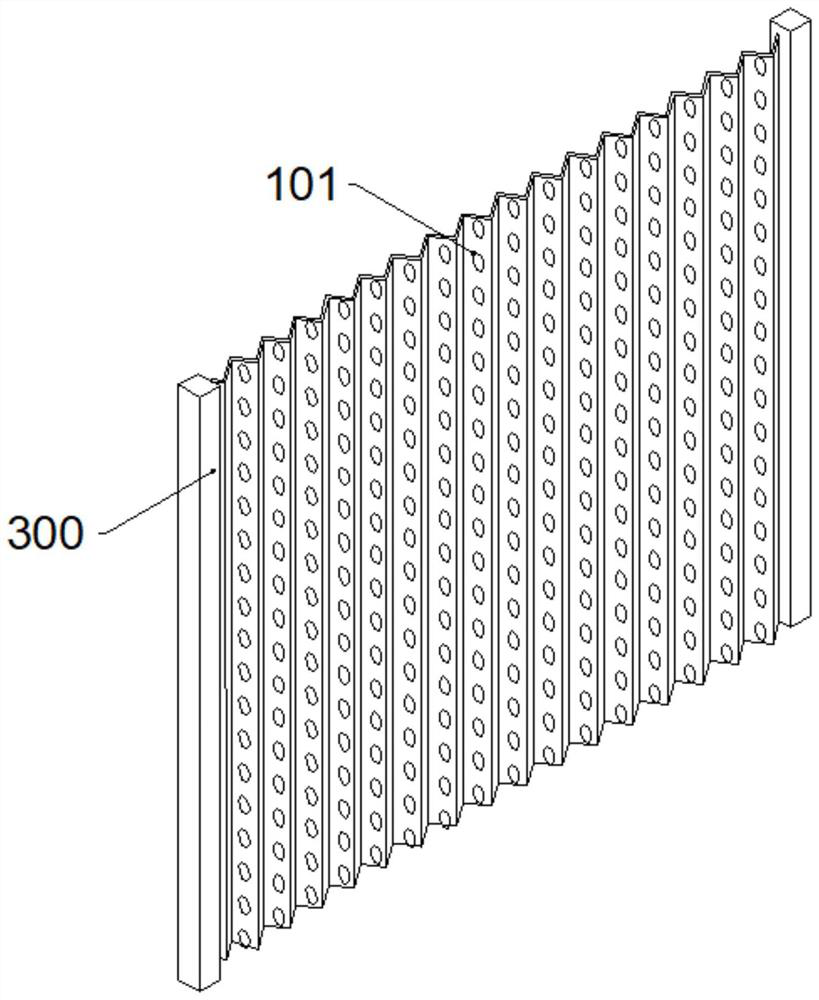

[0049] Such as Figure 1~4 An assembled double-layer corrugated steel plate composite shear wall is shown, the shear wall includes two vertical steel pipes 300 and a prefabricated shear wall 100 assembled in the two vertical steel pipes 300, the prefabricated shear wall 100 includes steel plates Mechanism 101, two groups of reinforcement mesh 102. Two groups of reinforcement meshes 102 are respectively fixedly installed on opposite side walls of the steel plate mechanism 101 . A concrete layer 103 is poured on the outside of the reinforcement mesh 102 .

[0050] The two sides of the upper end of the steel plate mechanism 101 are respectively welded and fixed with embedded inserting plates 400. The embedded inserting plates 400 are corrugated and compatible with the steel plate mechanism 101. The lower ends of the steel plate mechanism 101 are respectively provided with embedded inserting plates 400. The matching slot 401, the pre-embedded slot 400, the concrete layer 103 on ...

Embodiment 2

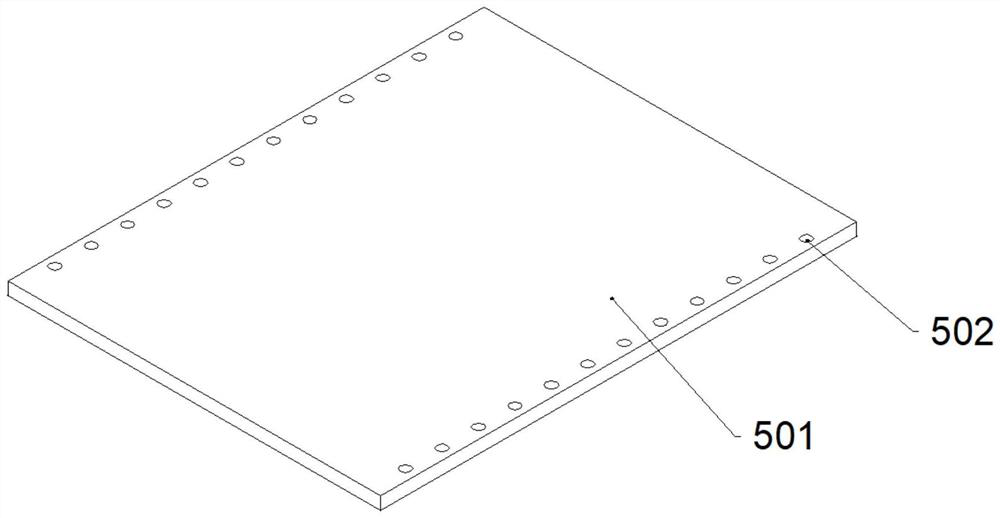

[0059] Such as Figure 5-11 An assembled double-layer corrugated steel plate composite shear wall is shown, the shear wall includes two vertical steel pipes 300 and a prefabricated shear wall 100 assembled in the two vertical steel pipes 300, the prefabricated shear wall 100 includes steel plates Mechanism 101, two groups of reinforcement mesh 102. Two groups of reinforcement meshes 102 are respectively fixedly installed on opposite side walls of the steel plate mechanism 101 . A concrete layer 103 is poured on the outside of the reinforcement mesh 102 .

[0060] The two sides of the upper end of the steel plate mechanism 101 are respectively welded and fixed with pre-embedded inserting plates 400, and the two sides of the lower end of the steel plate mechanism 101 are respectively provided with insertion slots 401 compatible with the embedded inserts 400, the embedded inserts 400 and the inserting slots 401 The concrete layer 103 on both sides and the lower end of the steel...

Embodiment 3

[0071] Such as Figures 12 to 14 An assembled double-layer corrugated steel plate composite shear wall is shown, the shear wall includes two vertical steel pipes 300 and a prefabricated shear wall 100 assembled in the two vertical steel pipes 300, the prefabricated shear wall 100 includes steel plates Mechanism 101, two groups of reinforcement mesh 102. Two groups of reinforcement meshes 102 are respectively fixedly installed on opposite side walls of the steel plate mechanism 101 . A concrete layer 103 is poured on the outside of the reinforcement mesh 102 .

[0072] The two sides of the upper end of the steel plate mechanism 101 are respectively welded and fixed with pre-embedded inserting plates 400, and the two sides of the lower end of the steel plate mechanism 101 are respectively provided with insertion slots 401 compatible with the embedded inserts 400, the embedded inserts 400 and the inserting slots 401 The concrete layer 103 on both sides and the lower end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com