Linear Fresnel type high-temperature and high-pressure heat collecting tube

A linear Fresnel, high temperature and high pressure technology, used in solar collectors, solar collectors using working fluid, solar thermal energy, etc., can solve the defects of glass tube and stainless steel tube sealing ring, glass tube and stainless steel tube shaft To solve the problems of different expansion amount, etc., to achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

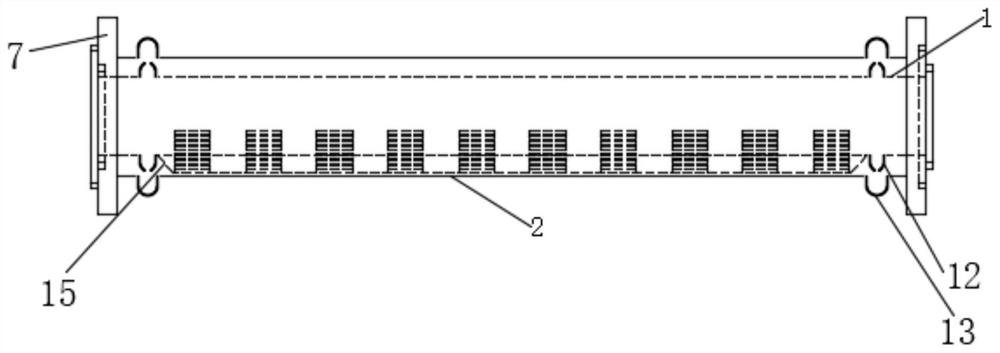

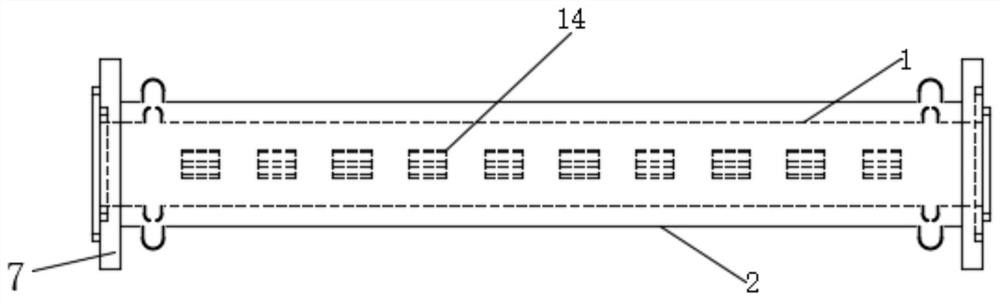

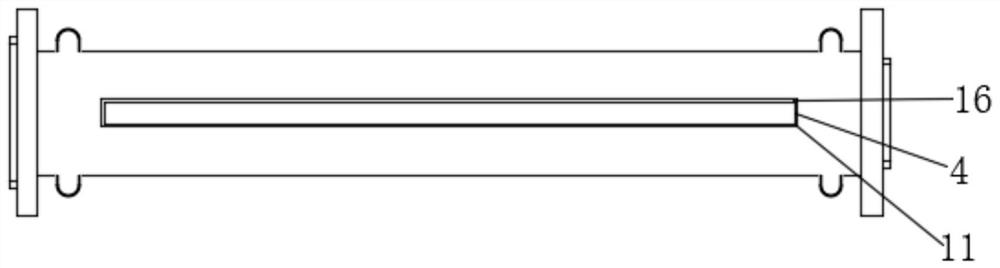

[0025] Such as Figure 1-4 As shown, a linear Fresnel type high-temperature and high-pressure heat collecting tube according to the present invention includes an inner tube 1 and an outer tube 2, and the two ends of the inner tube 1 and the outer tube 2 are fixedly connected by a flange 7, and the inner tube 1 and the outer tube 2 are fixedly connected by a flange 7. One side of the tube 1 is fixedly connected with an inner tube special-shaped cavity 3, the two ends of the inner tube 1 are provided with an inner tube expansion joint 12, the inner tube 1 is provided with a special-shaped cavity shrinkage port 15, and the outer tube 2 is provided with an outer tube Expansion joint 13, the lower part of the special-shaped cavity 3 of the inner tube is fixedly connected with a cooling plate 5, the cooling plate 5 is fixedly connected with a cooling fin 6, the outer tube 2 is provided with a card slot 11, through the glass sheet 4, The filling seal 16, the filling seal mounting gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com