Building door and window on-site airtight performance detection device

A technology for building doors and windows and detection devices, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, etc. It can solve the problems of reducing detection efficiency, single function, and increasing labor intensity of staff, so as to improve detection efficiency and reduce labor intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

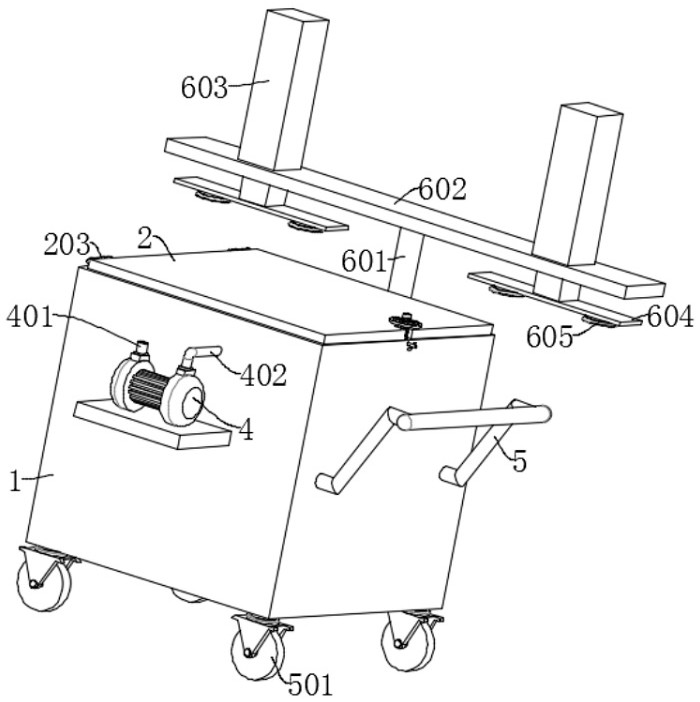

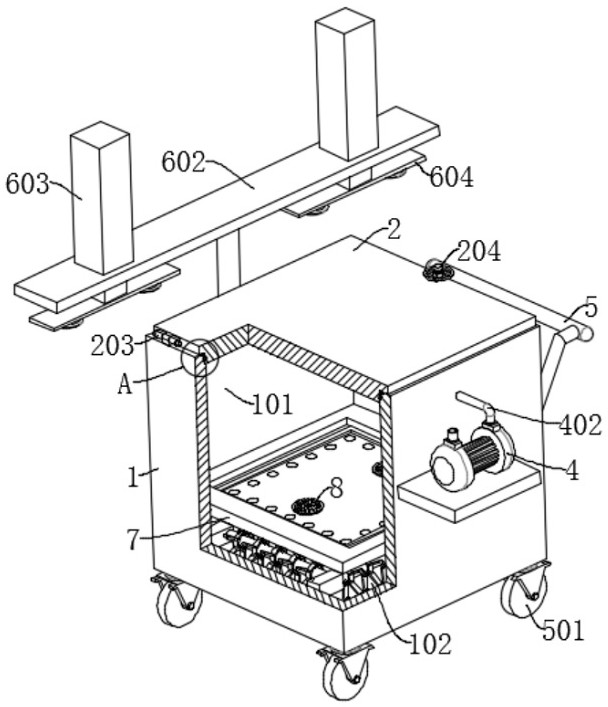

[0031] refer to Figure 1-8 , an on-site airtight performance detection device for building doors and windows, comprising a detection box 1, a sealing cover 2, the sealing cover 2 is rotatably connected to the detection box 1, and also includes: a pressurized chamber 101 arranged in the detection box 1, and increasing The bottom of the pressure chamber 101 is provided with a detection chamber 102 that can accurately detect the leaking parts of doors and windows; the motor 6 is fixedly connected to the side wall of the detection box 1, and the output end of the motor 6 is fixedly connected with a rotating shaft 1 601, which is fixed on the rotating shaft 1 601. Connected with a support plate 602, the support plate 602 is fixedly connected with a cylinder 603, the output end of the cylinder 603 is fixedly connected with a connecting plate 604, and the bottom of the connecting plate 604 is fixedly connected with a vacuum suction cup 1 605;

[0032] The hinge 203 is fixedly connec...

Embodiment 2

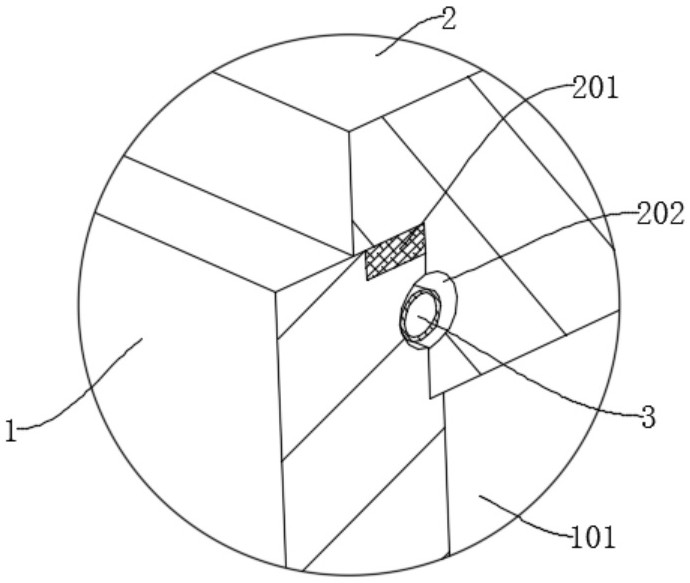

[0041] refer to figure 1 , 5 And 6, an on-site airtight performance detection device for building doors and windows, which is basically the same as Embodiment 1, furthermore, the locking part includes a screw mandrel 204 and a nut 205, the screw mandrel 204 is fixedly connected to the detection box 1, and the nut 205 Threaded connection with the screw rod 204; when the sealing cover 2 is closed, first put the nut 205 on the screw rod 204, and then turn the nut 205, at this time the nut 205 moves to the side of the detection box 1, pushing the seal on the inner side of the sealing cover 2 The pad 201 is closely attached to the top of the detection box 1, thereby improving the sealing performance of the connection between the sealing cover 2 and the detection box 1, avoiding air pressure leakage, and affecting the detection result of the wind pressure resistance of the doors and windows.

Embodiment 3

[0043] refer to Figure 4 , 7 And 8, an on-site airtight performance detection device for building doors and windows, which is basically the same as Embodiment 1, furthermore, the fixed parts include a sealing strip 702, a vacuum suction cup 28, a piston cylinder 801, an electric telescopic rod 803, and a sealing strip 702 1. Vacuum suction cup two 8 are all fixedly connected on the detection board 7, the piston cylinder 801 and the electric telescopic rod 803 are all fixedly connected on the bottom of the detection board 7, the vacuum suction cup two 8 is connected with the piston cylinder 801 through the third conduit 804, and the piston cylinder 801 There is a piston plate 802 slidingly connected inside, and the piston plate 802 is fixedly connected with the output end of the electric telescopic rod 803; when the airtightness of doors and windows is tested, the electric telescopic rod 803 is started, and the electric telescopic rod 803 drives the piston plate 802 to move aw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com