Intelligent feeding and discharging carrying system

A handling system and intelligent technology, applied in the direction of general control system, control/regulation system, comprehensive factory control, etc., to achieve the effect of saving handling costs, ensuring effectiveness and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

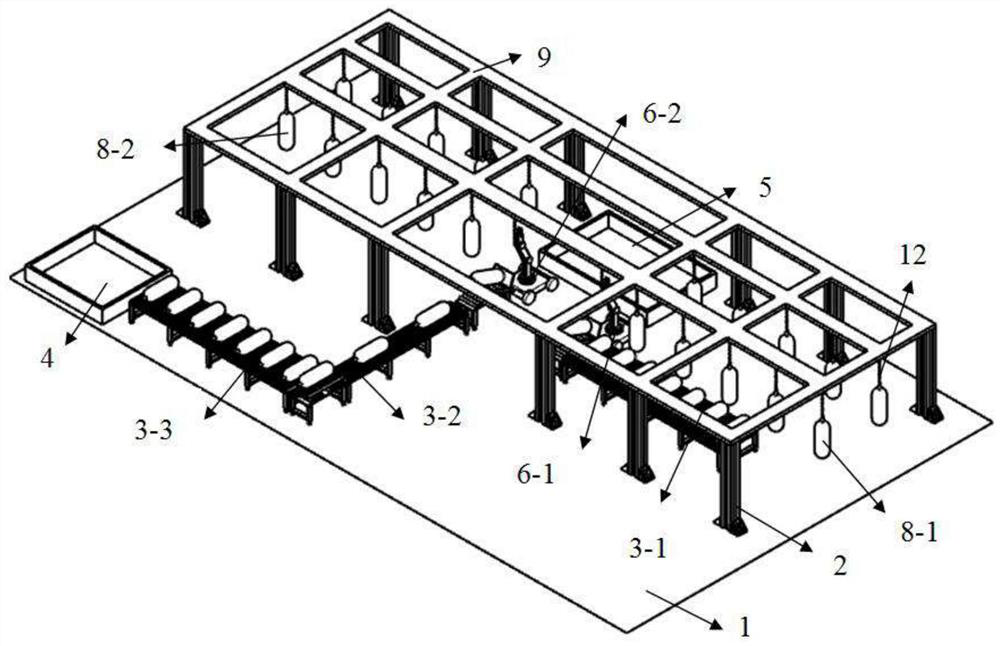

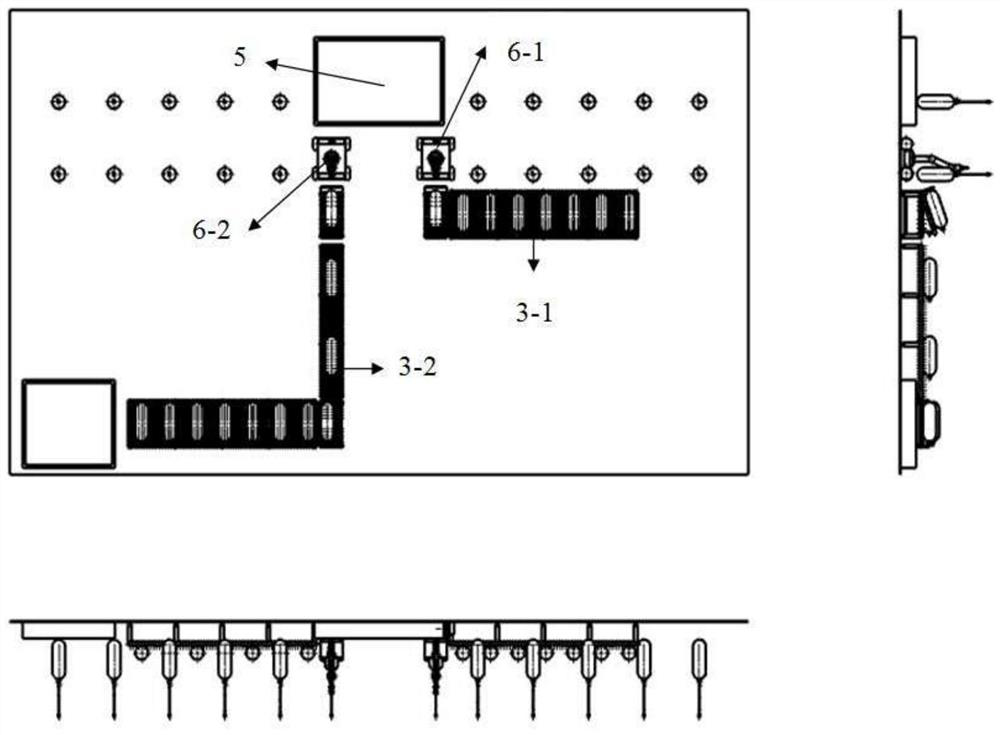

[0040] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

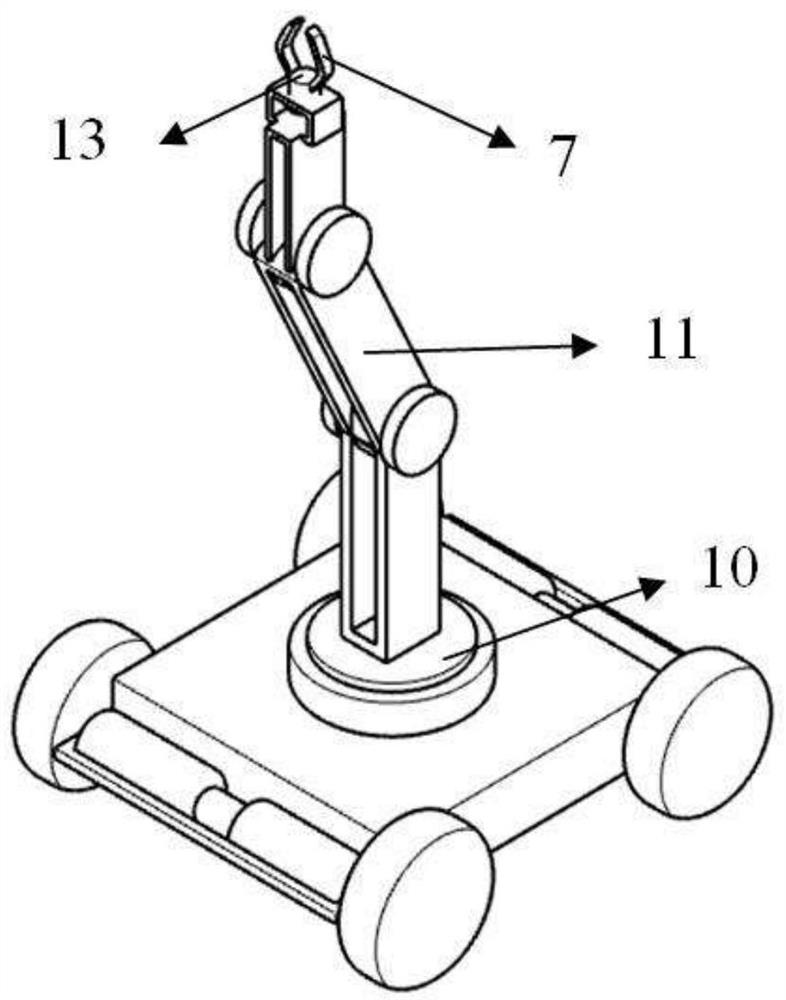

[0041] Such as figure 1As shown, the present invention is an intelligent loading and unloading system, including a frame 2, the frame 2 is fixedly installed on the ground 1, a support structure 9 is installed on the upper surface of the frame 2, and the support structure 9 A transmission mechanism is installed below the transmission mechanism, and rope hooks 12 are installed below the transmission mechanism, and the rope hooks 12 are evenly arranged according to a certain distance, and unsprayed and dried gas tanks are hung below the rope hooks 12. 8-1 and the gas tank 8-2 that has been sprayed and dried, and the gas tank 8-1 that has not been sprayed and dried is delivered to At the first intelligent mobile robot 6-1, the first intelligent mobile robot 6-1 hangs the rope hook on the round hole of the unsprayed and dried gas tank after judging...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com