Reliability evaluation method for performance degradation of spinning frame

A spinning frame and reliability technology, which is applied in the field of reliability evaluation for the performance degradation of the spinning frame, can solve the problems of spinning frame failure and insufficient utilization of performance degradation status information, and achieves good maintenance management, avoids risks, and improves cost. Effect of yarn quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

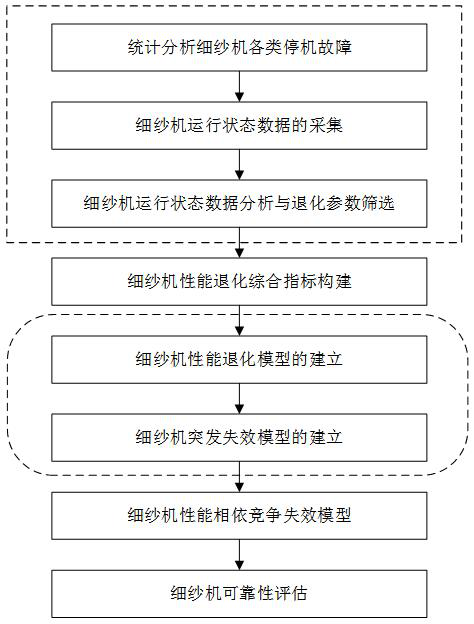

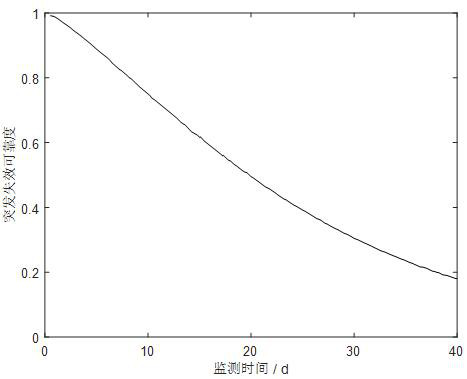

Method used

Image

Examples

Embodiment

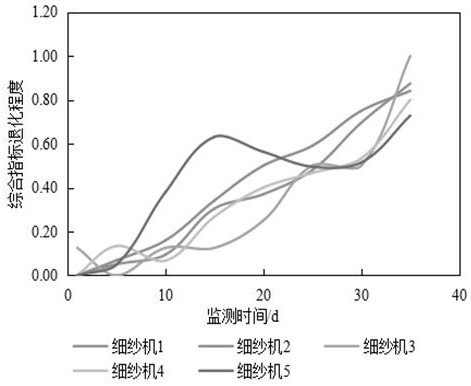

[0164] S1. Collect the fixed length, current bobbin length, current machine total weight, spindle speed, front roller speed, middle roller speed, front roller line speed, twist, total draft multiple, motor power, and rear roller speed of a textile group spinning frame. The data of 15 parameters, such as roller speed, ring diameter, ring bar ascending speed, ring bar descending speed, and ring bar step-up, have been collected for 500 hours in total.

[0165] S2. Calculated sensitivity by introducing three criteria of sensitivity, relevance and importance ,relativity , parameter importance Carry out comprehensive consideration to obtain the standard of comprehensive screening parameters .

[0166]

[0167] A total of 6 characterization parameters that can describe the degradation trajectory of the equipment are selected. These 6 parameters are spindle speed, front roller speed, front roller line speed, total draft multiple, motor power, and ring plate rising speed. On...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com