Head heating structure of soybean milk machine

A technology of heating structure and soybean milk machine, which is applied to heating devices, cooking utensils, household appliances, etc., can solve the problems of low safety guarantee, increased cost, complex structure, etc., and achieve the effects of simplifying structure, eliminating burns, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

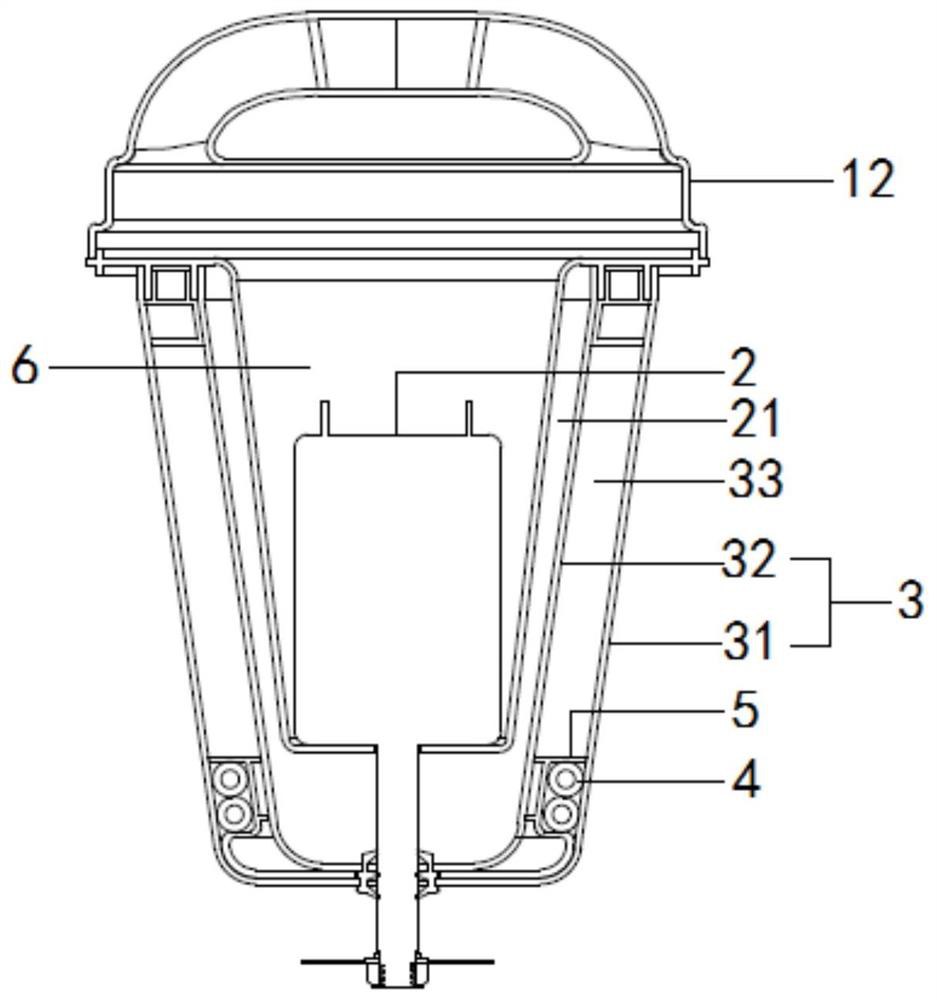

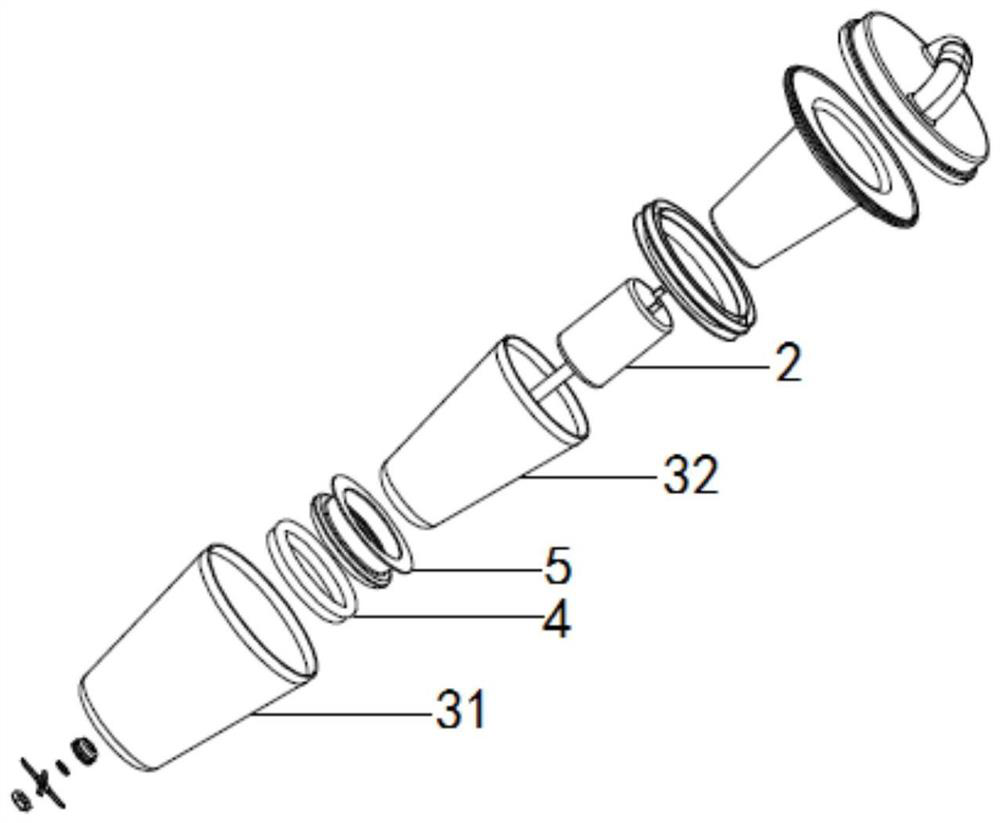

[0026] see Figure 1 to Figure 5 , this embodiment provides a head heating structure of a soybean milk machine, wherein the soybean milk machine includes a cup body 1 and a head assembly, the head assembly is detachably installed in the cup body 1, and the head assembly includes a head body 2, The double-layer protection mechanism 3 and the heating tube 4 , the double-layer protection mechanism 3 is detachably set on the machine head body 2 , and the heating tube 4 is fixedly installed in the interlayer 33 of the double-layer protection mechanism 3 .

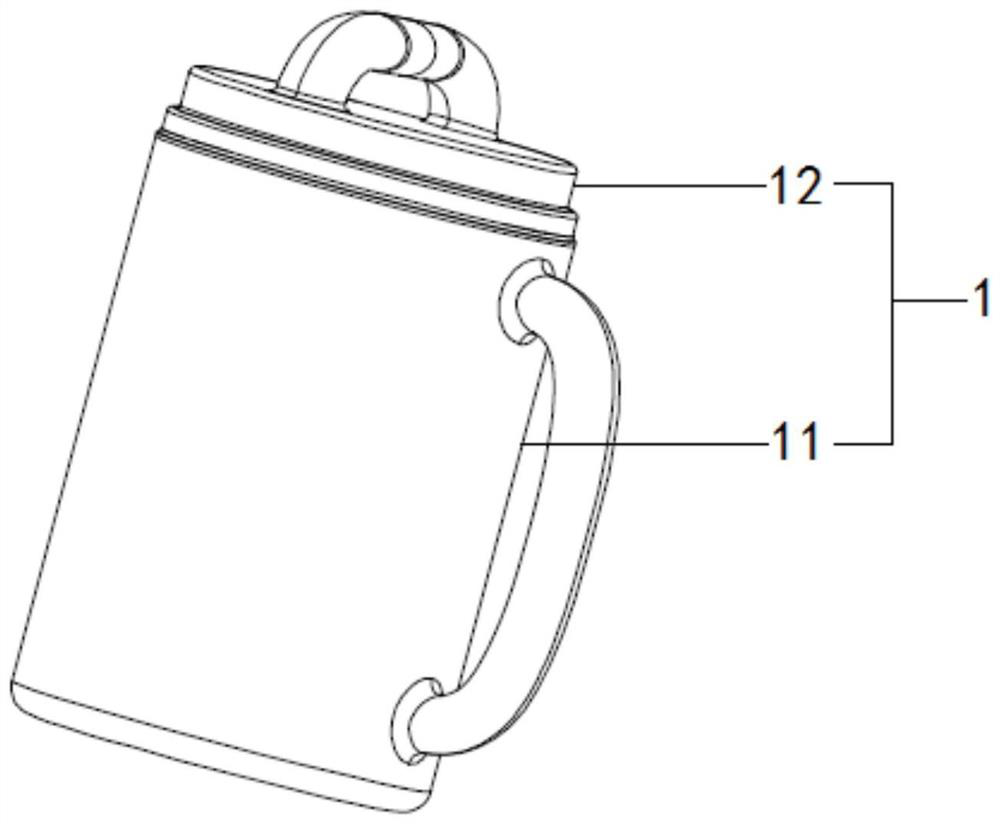

[0027] continue to see Figure 1 to Figure 5 , the cup body 1 includes a cup body 11 and a cup cover 12, the cup cover 12 is detachably installed on the cup body 11, the head assembly is fixedly installed on the cup cover 12, the double-layer protection mechanism 3 includes a stainless steel outer cover 31 and a stainless steel inner cover 32. An interlayer 31 is formed between the stainless steel outer cover 31 and the stainle...

Embodiment 2

[0032] see Figure 1 to Figure 5 , the figure shows a head heating structure of a soymilk machine provided by Embodiment 2 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: the soymilk machine includes The cup body 1 and the machine head assembly, the machine head assembly is detachably installed in the cup body 1, the machine head assembly includes the machine head body 2, the double-layer protection mechanism 3 and the heating tube 4, the double-layer protection mechanism 3 is detachably set in the On the machine head body 2, and the heating tube 4 is fixedly installed in the interlayer 33 of the double-layer protection mechanism 3. The double-layer protection mechanism 3 includes a stainless steel outer cover 31 and a stainless steel inner cover 32. The stainless steel outer cover 31 is evenly opened with multiple heat exchange channels The heat exchange channel has two...

Embodiment 3

[0034] see Figure 1 to Figure 5 , the figure shows a head heating structure of a soymilk machine provided by Embodiment 3 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: the soymilk machine includes The cup body 1 and the machine head assembly, the machine head assembly is detachably installed in the cup body 1, the machine head assembly includes the machine head body 2, the double-layer protection mechanism 3 and the heating tube 4, the double-layer protection mechanism 3 is detachably set in the On the machine head body 2, and the heating tube 4 is fixedly installed in the interlayer 33 of the double-layer protection mechanism 3, the machine head body 2 is located in the built-in cavity 6, and the cup cover 12 is provided with a vent connected to the built-in cavity 6, The built-in cavity 6 is also electrically connected with a heat dissipation component. The heat dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com