Automatic welding machine for ultrafiltration membrane pipe fitting tee joint

A technology of automatic welding machine and pipe fitting tee, applied in the field of ultrafiltration water treatment, can solve problems such as high cost and unsightly appearance, and achieve the effects of reducing production cost, improving automation, and improving hot-melt welding efficiency and welding accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

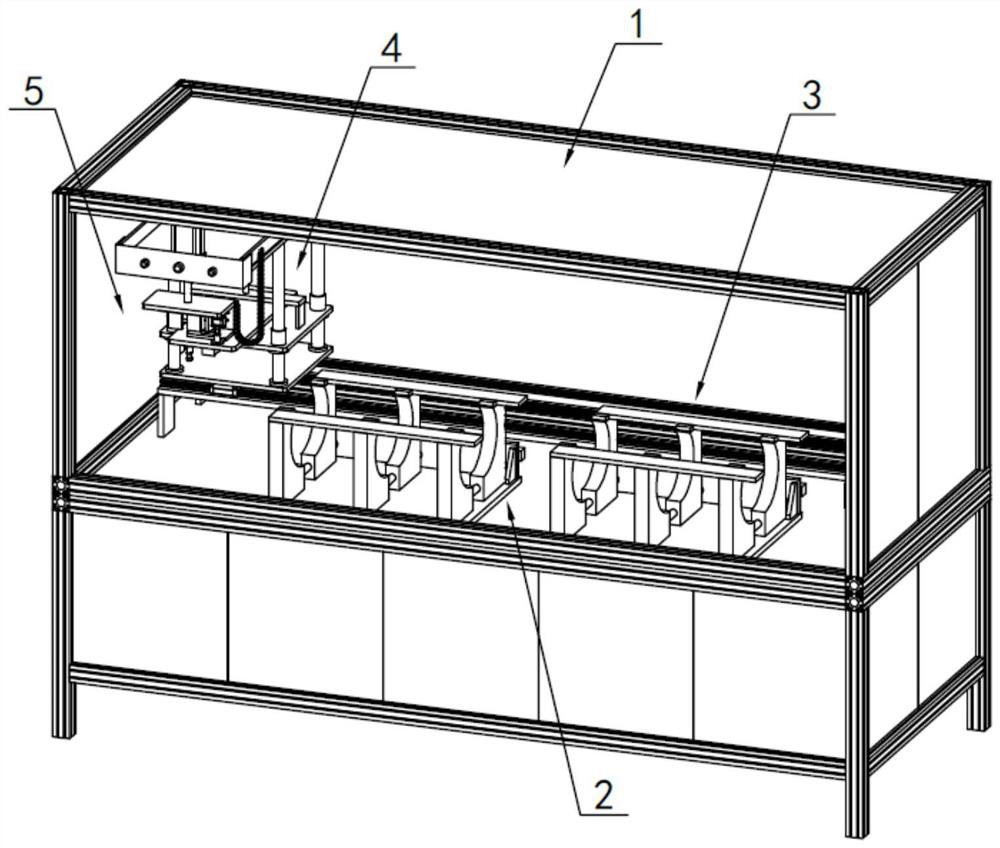

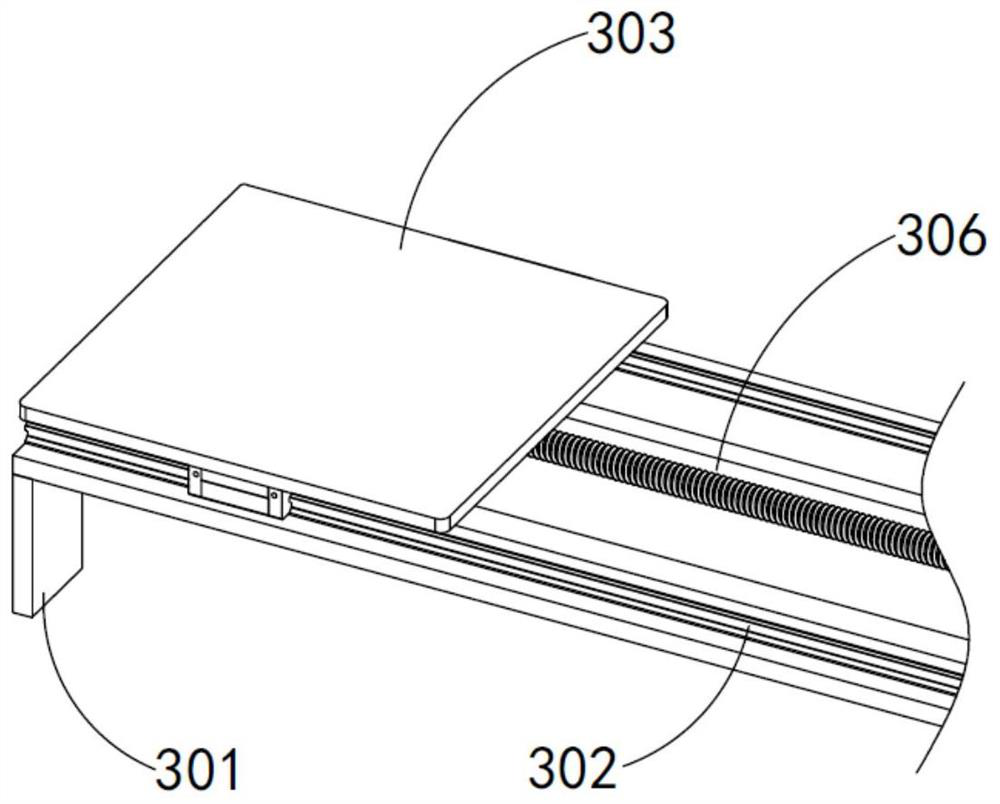

[0035] Such as Figure 1 to Figure 12 As shown, a kind of ultrafiltration membrane pipe fitting tee automatic welding machine includes the first fixing mechanism 2 arranged on the frame 1, and the first fixing mechanism 2 is used to fasten and limit the ultrafiltration outer tube 6, The rear side of the first fixing mechanism 2 is provided with a translation mechanism 3, and a hot-melt mechanism 4 is slidably arranged on the translation mechanism 3, and a matching second fixing mechanism 5 is also arranged on the said hot-melt mechanism 4, so that The second fixing mechanism 5 is used to clamp and fix the curved surface tee 7, the hot-melt mechanism 4 includes a first hot-melt assembly 401 and a second hot-melt assembly 402, and the first hot-melt assembly 401 and the second hot-melt assembly The hot-melt assembly 402 performs hot-melt treatment on the interface 601 of the ultrafiltration outer tube 6 and the arc-shaped port 701 of the curved surface tee 7 respectively, and th...

Embodiment 2

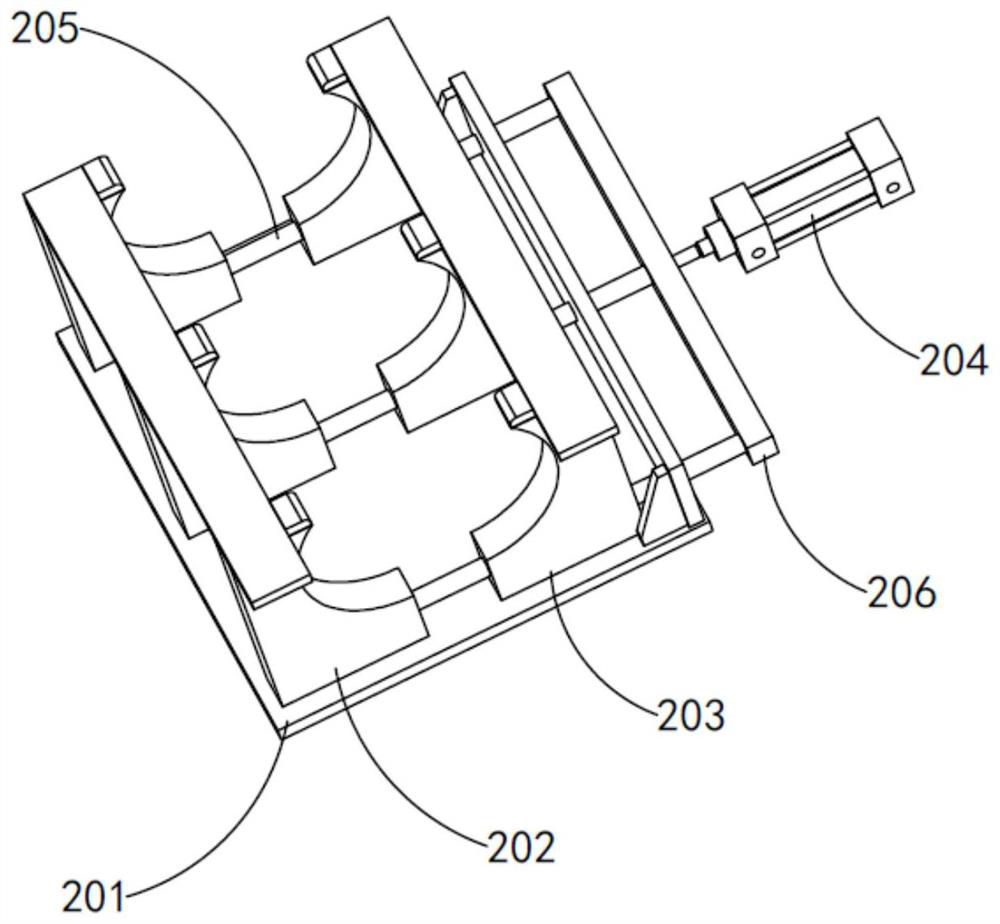

[0048] Such as figure 2 As shown, the parts that are the same as or corresponding to those in the first embodiment adopt the reference numerals corresponding to the first embodiment. For the sake of simplicity, only the differences from the first embodiment are described below; the differences between the second embodiment and the first embodiment The difference is that: the fastener a202 and the fastener b203 in the first fixing mechanism 2 are equipped with aluminum bushings to fasten and clamp outer tubes with different outer diameters.

[0049] The working process is as follows:

[0050] The operator first puts the ultrafiltration outer tube 6 on the first fixing mechanism 2, and then controls the cylinder a204 to push the push rod a205 to make the fastener b203 move closer to the fastener a202 to fasten and hold the ultrafiltration outer tube 6. After the fastening of the pipe 6 is completed, the operator places the curved surface tee 7 between the clamping block a504 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com