Full-automatic packaging device and method for PET packaging bags

A packaging bag, fully automatic technology, applied in the field of packaging, can solve the problems of clamping and squeezing items to be packaged, single packaging function of the device, and poor packaging effect of the device, so as to achieve the effect of improving packaging effect, improving packaging efficiency, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

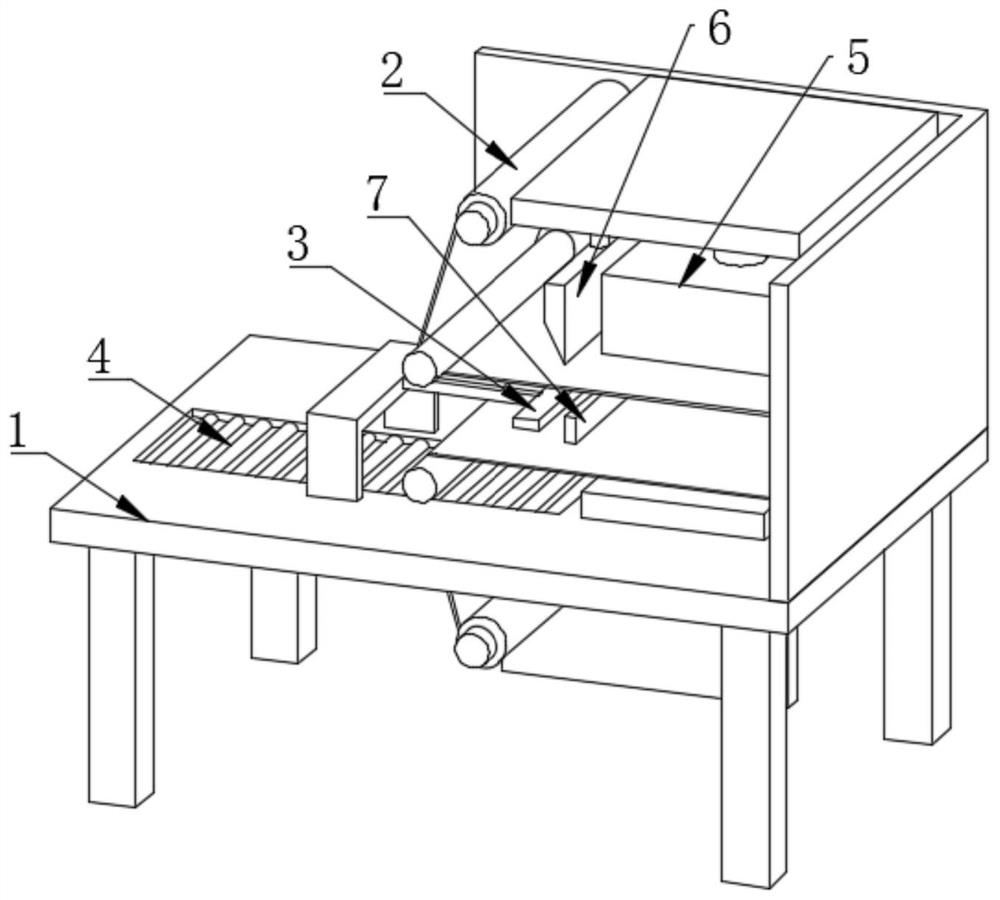

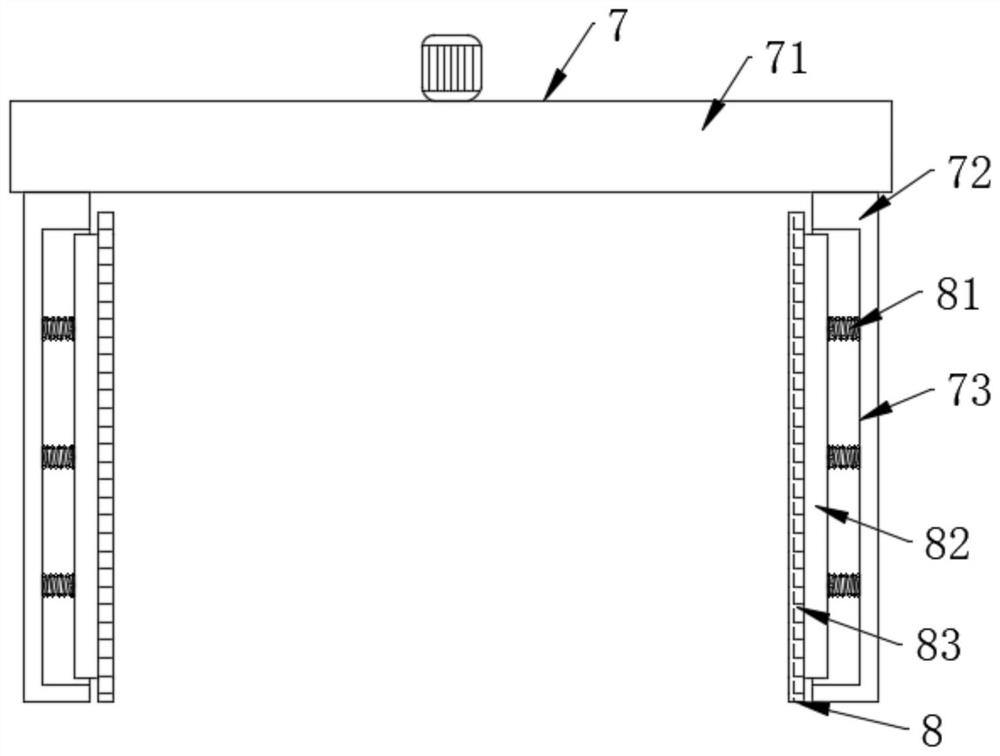

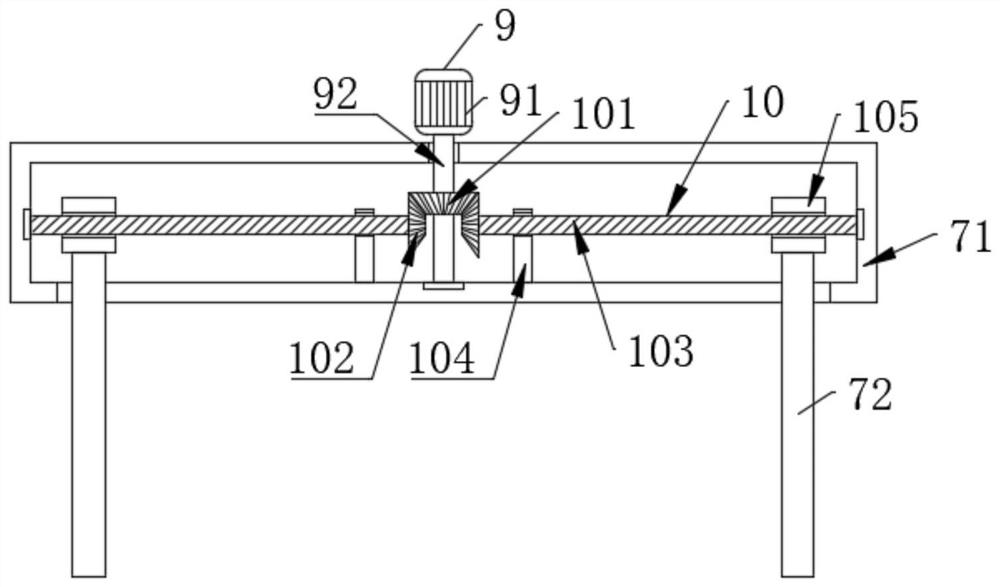

[0034] Such as Figure 1-Figure 2 As shown, the fully automatic packaging device for PET packaging bags in this embodiment includes a workbench 1, a conveying mechanism 2, a heating mechanism 3, a conveying mechanism 4, a pressing mechanism 5, and a cutting mechanism 6, and the conveying mechanism 2 is symmetrically arranged on the workbench 1 The top and bottom of the top and bottom of the workbench 1, and the conveying mechanism 2 is connected with a packaging bag, the heating mechanism 3 is movably arranged on the top surface of the workbench 1, the transmission mechanism 4 is embedded in the inner side of the workbench 1, and the transmission mechanism 4 is located at the bottom of the heating mechanism 3 , the pressing mechanism 5 and the cutting mechanism 6 are both arranged on the top of the heating mechanism 3; it also includes a clamping mechanism 7 for clamping the items to be packaged;

[0035] The clamping mechanism 7 includes a mounting plate 71 and a clamping pla...

Embodiment 2

[0054] Such as Figure 1-Figure 2 As shown, the fully automatic packaging device for PET packaging bags in this embodiment includes a workbench 1, a conveying mechanism 2, a heating mechanism 3, a conveying mechanism 4, a pressing mechanism 5, and a cutting mechanism 6, and the conveying mechanism 2 is symmetrically arranged on the workbench 1 The top and bottom of the top and bottom of the workbench 1, and the conveying mechanism 2 is connected with a packaging bag, the heating mechanism 3 is movably arranged on the top surface of the workbench 1, the transmission mechanism 4 is embedded in the inner side of the workbench 1, and the transmission mechanism 4 is located at the bottom of the heating mechanism 3 , the pressing mechanism 5 and the cutting mechanism 6 are both arranged on the top of the heating mechanism 3; it also includes a clamping mechanism 7 for clamping the items to be packaged;

[0055] The clamping mechanism 7 includes a mounting plate 71 and a clamping pla...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap