Multi-section oxygen generation ball for organic pollutant treatment

An organic pollutant, multi-stage technology, applied in water pollutants, water/sewage treatment, biological treatment devices, etc., can solve the problems of small scope of action, poor effect, inability to supplement dissolved oxygen, etc. The effect of the effect, the effect of improving the scope of delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

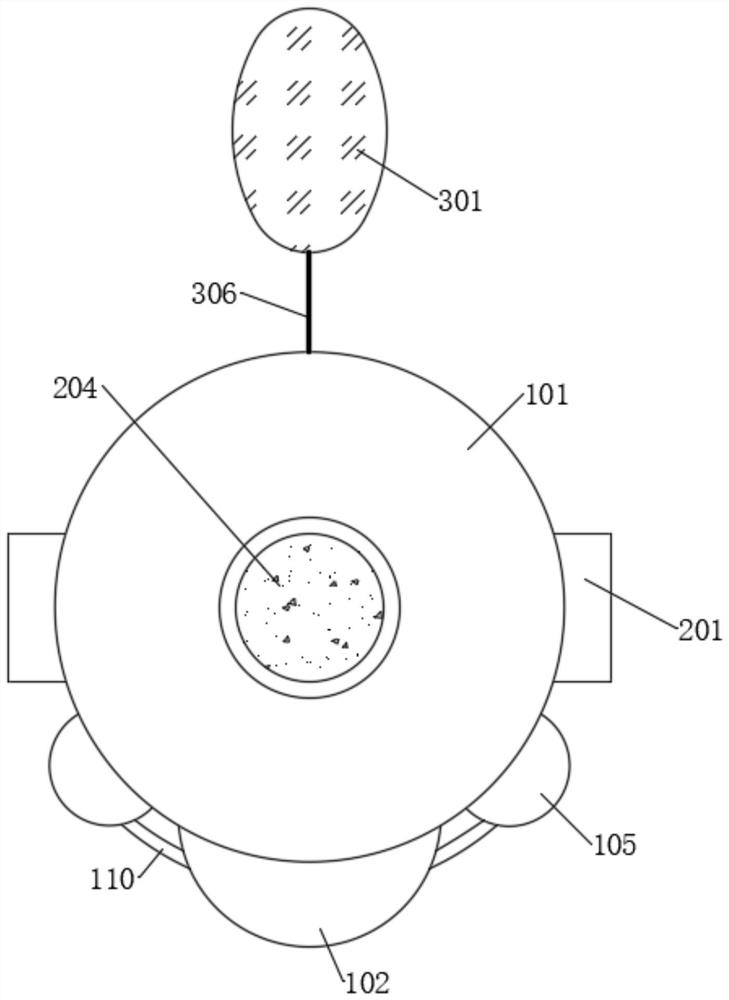

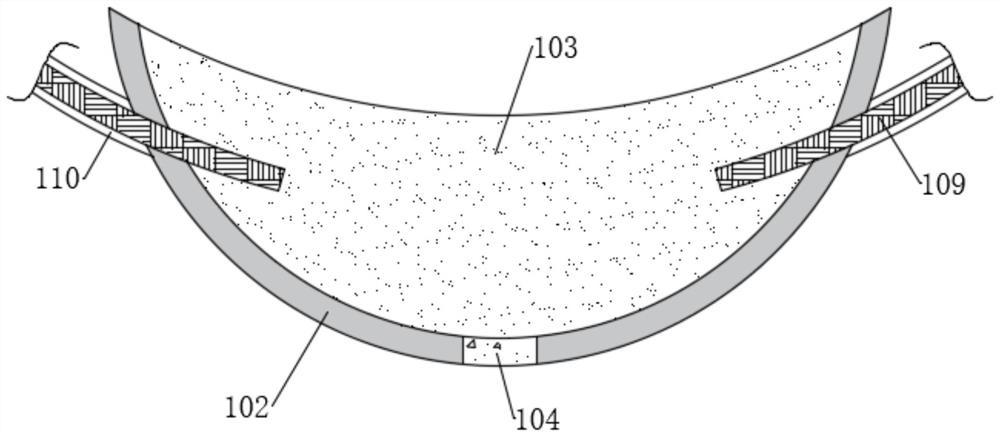

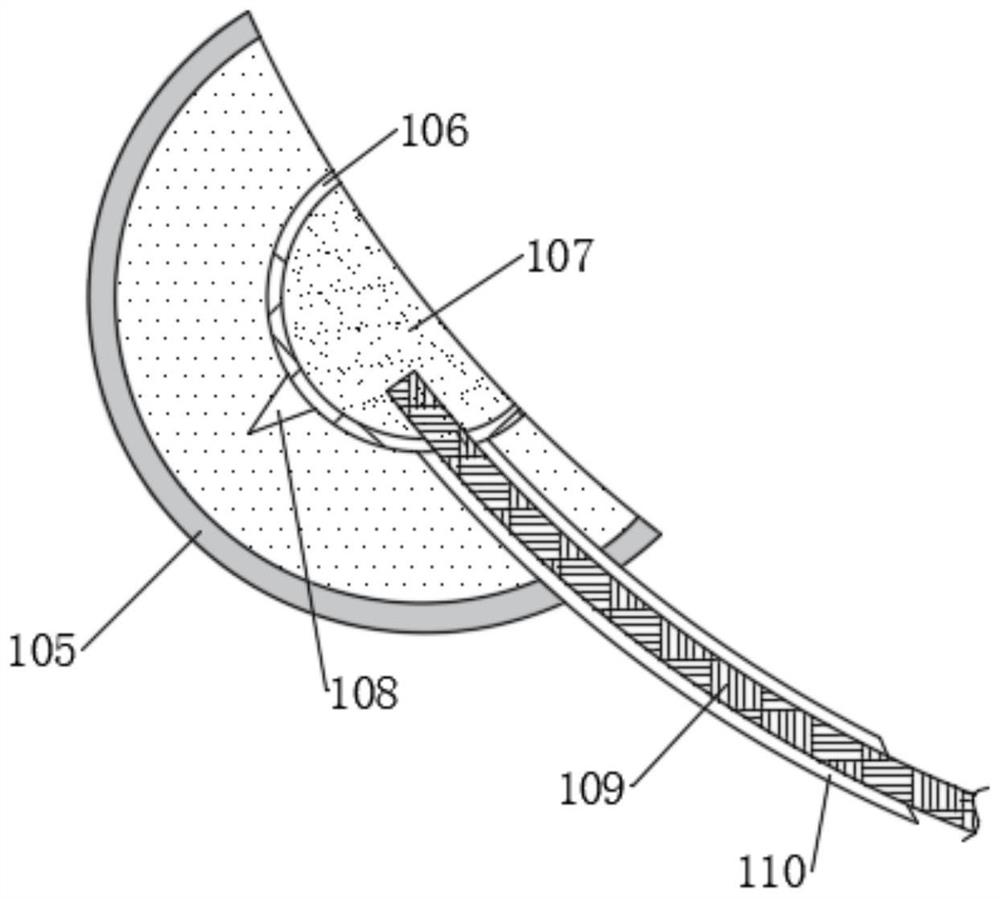

[0035] see Figure 1-3 and Figure 7 , a multi-stage oxygen-making sphere for organic pollutant treatment, comprising a central main sphere 101, the bottom end of the central main sphere 101 is fixedly connected with a hemispherical shallow discharge shell 102, and the shallow release The shell 102 is filled with an oxygen generator 103 for the shallow layer, and the bottom end of the oxygen generator 103 for the shallow layer is provided with a release hole, and a water-soluble plugging block matching it is sealed in the release hole 104, the central main sphere 101 is filled with hydrogen gas, the inflatable control buoyancy bag 105 is filled with hydrogen gas, and the water-soluble plugging block 104 is made of water-soluble environmental protection materials, such as Figure 7 As shown, under the action of the hydrogen in the central main sphere 101 and the inflatable control buoyancy bag 105, combined with the buoyancy of water, the oxygen-making ball can float on the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com