Alum feeding device for sewage treatment tank

A technology of sewage treatment tank and feeding device, which is applied in water/sewage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. It can solve the problems of large blind area for feeding and close water area where the device cannot be placed. , to achieve the effect of strong practicability, simple and exquisite structure, and avoid casting blind spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

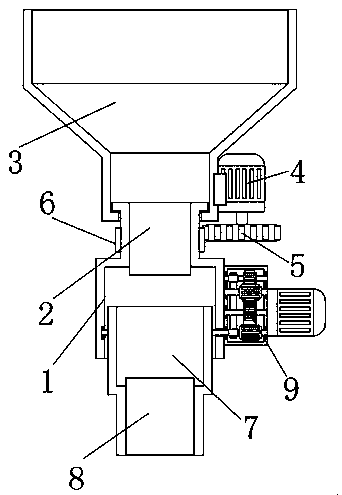

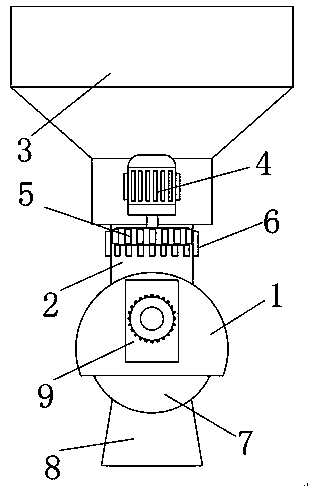

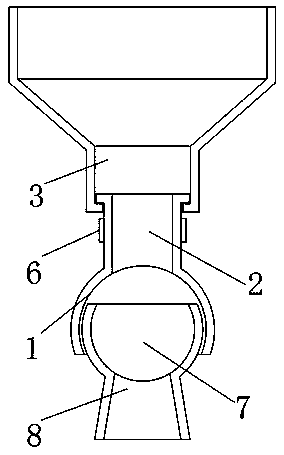

Image

Examples

Embodiment 1

[0023] Embodiment one: power mechanism 9 comprises casing 91, second motor 92, running wheel 93, second gear 94, the 3rd gear 95, second gear 96 and second gear 97, and the right side of casing 91 is equipped with second Motor 92, and the drive shaft of the second motor 92 extends to the inside of the casing 91 and is welded with a runner 93, and the left end of the central axis of the runner 93 is connected with the inner wall of the casing 91 by an embedded bearing, and the top of the runner 93 is provided with a second Gear 94, the third gear 95 is arranged below the running wheel 93, and the second gear 96 is meshed above the second gear 94. The two ends of the running wheel 93, the second gear 94 and the third gear 95 all pass through the inner wall of the casing 91 The inner bearing is connected, the central shaft of the second gear 96 is connected with the central shaft of the third gear 95 through a belt and a pulley, and the left end of the central shaft of the third g...

Embodiment 2

[0024] Embodiment 2: The first motor 4 starts to drive the first gear 5 to rotate, and the first gear 6 drives the feed opening 2 to rotate, so that the outer cylinder 1 and the inner cylinder 7 are rotated, and the alum in the storage cylinder 3 passes through the outlet When the feed port 8 is spilled, the alum rotates through the discharge port 8 to generate centrifugal force, which further improves the range of delivery of the device, and cooperates with the front and rear offset of the discharge port 8 to control the water area in a circular area below the device. Blind spots are placed evenly, with strong practicability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com