Squeezing device for blueberry processing

A blueberry and extrusion box technology, applied in the fields of application, juice extraction, food science, etc., can solve problems such as single structure, easy to block the feeding channel, and single function, so as to speed up the discharge speed, improve the squeezing effect, and improve the practicality. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

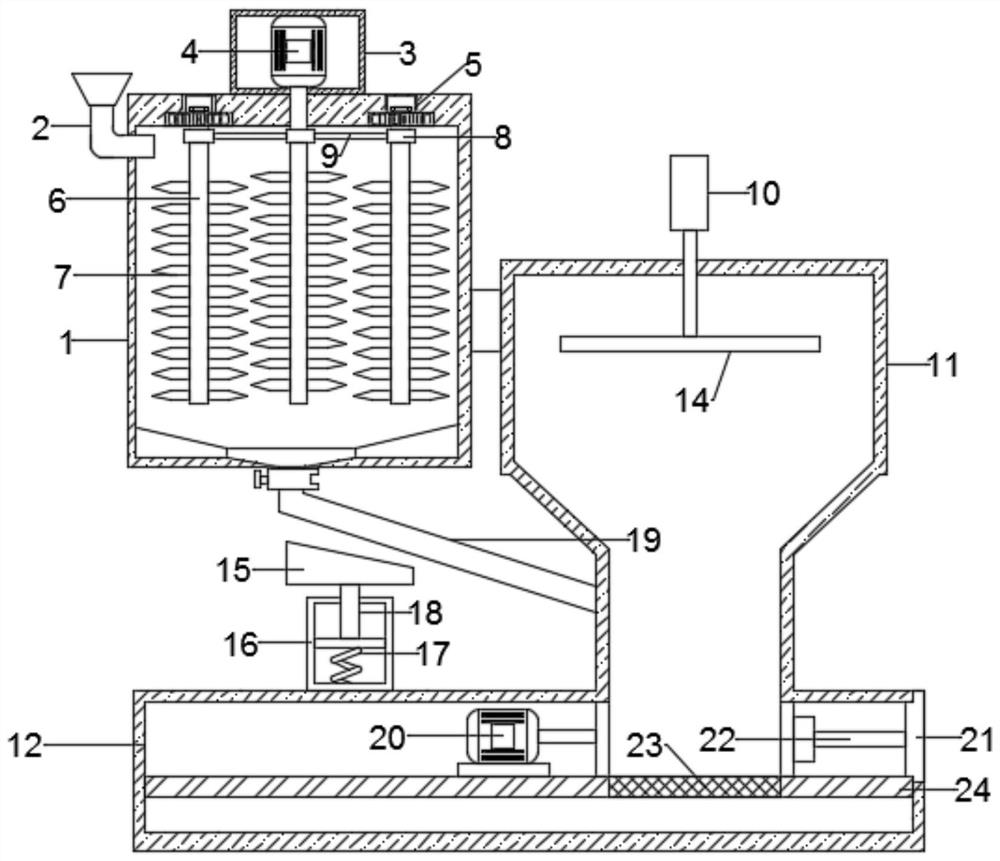

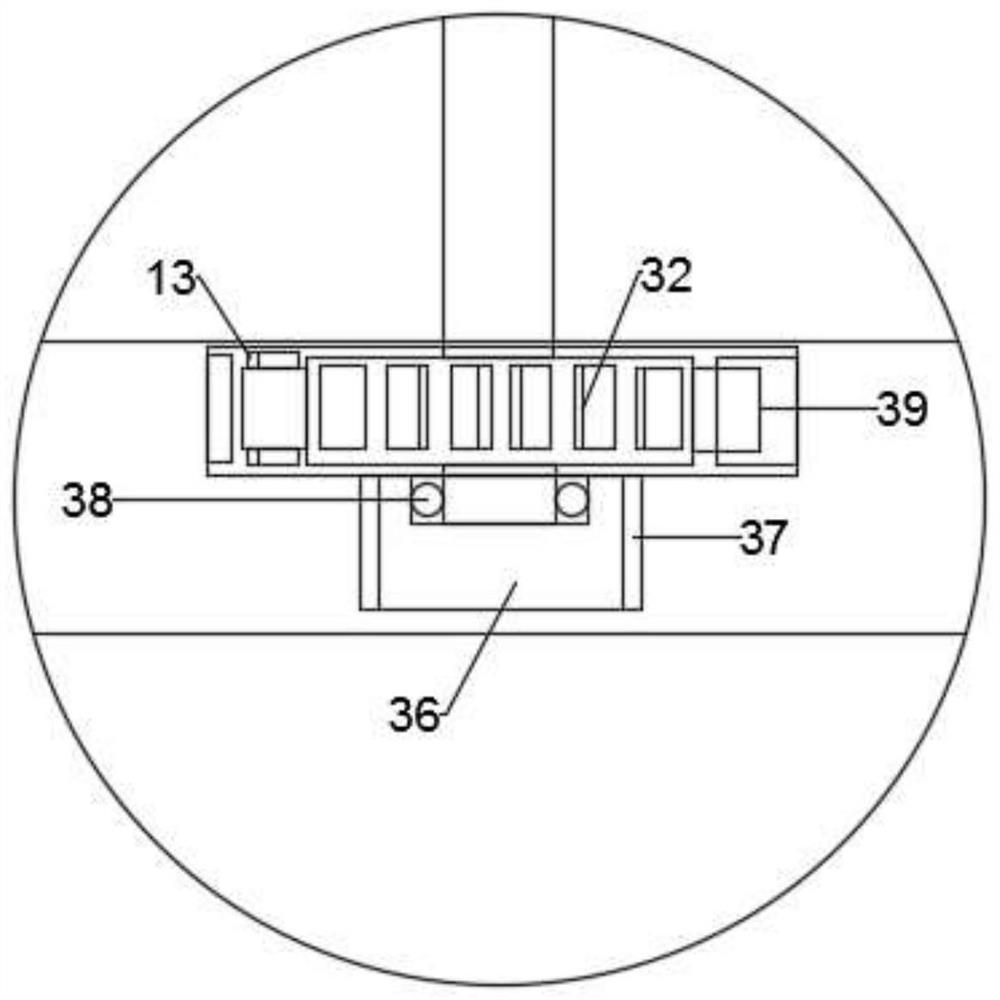

[0022] see Figure 1~2 , in an embodiment of the present invention, a blueberry processing pressing device includes a crushing box 1, a driving mechanism 5, a squeezing box 11, a squeezing mechanism, a vibrating mechanism, and a slag removal mechanism, and the crushing box 1 is provided with a driving mechanism 5. A feed hopper 2 is fixedly installed on one side of the top of the crushing box 1, a vibrating mechanism is fixedly installed under the driving mechanism 5, and an extrusion box 11 is fixedly installed on one side of the crushing box 1. An extruding mechanism is arranged in the box 11, and a storage box 12 is fixedly arranged under the extruding mechanism, and a slag removing mechanism is arranged between the storage box 12 and the extruding box 11. The blueberries are primary crushed, and the crushed blueberries are sent into the extrusion box 11, and the vibration mechanism can quickly send the crushed blueberries into the extrusion box 11, and the extrusion mechan...

Embodiment 2

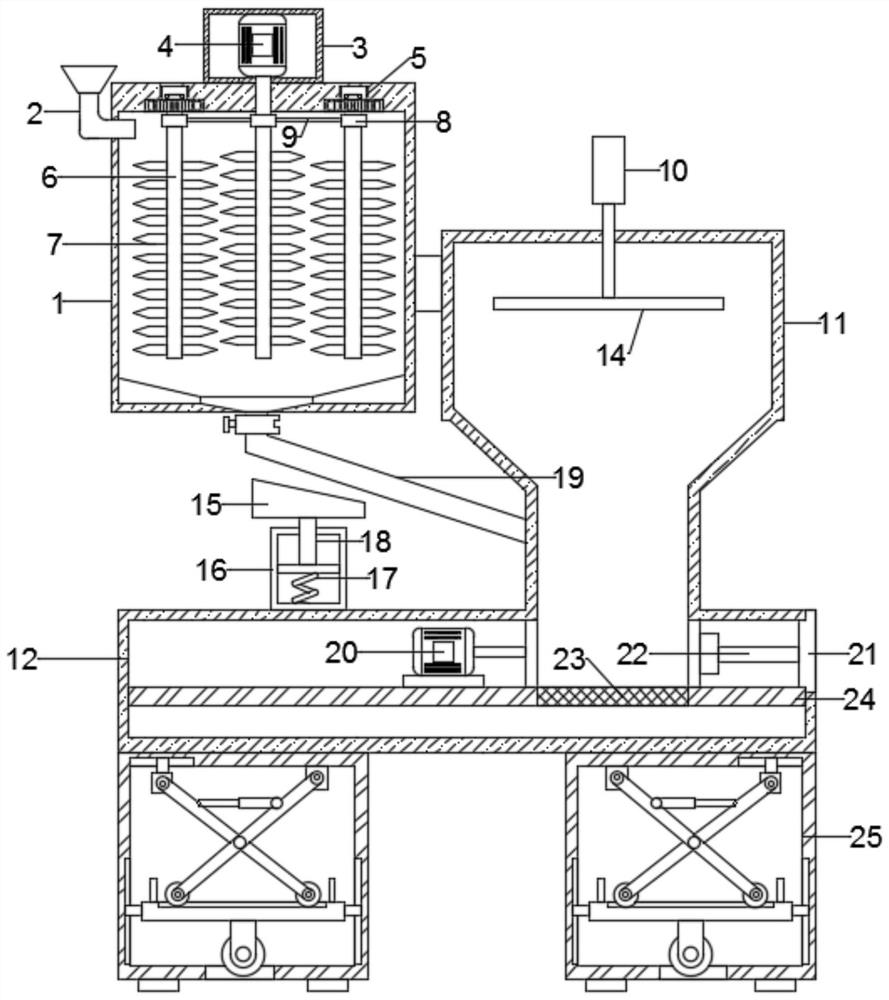

[0029] see Figure 3-4 , The difference between this embodiment and Embodiment 1 is that it also includes a limit mechanism, and the limit mechanism includes a placement cavity 25, a first chute 29, a second slider, an electric telescopic rod three 28, and a partition 31 and moving wheels 34, the lower surface of the storage box 12 is evenly distributed with a plurality of placement cavities 25, the top side of the placement cavity 25 is provided with a first chute 29, and the first chute 29 is slidingly provided with a first Two sliders, the lower surface of the second slider is fixedly provided with a fixed block 26, and the side of the top of the placement cavity 25 away from the second slider is fixedly provided with a fixed block 26, and the two fixed blocks 26 are fixed. A hinged rod 27 is hinged, and an electric telescopic rod 3 28 is hinged between the two hinged rods 27. The end of the hinged rod 27 away from the fixed block 26 is provided with a roller 35, and the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com