Dust removal device for fused quartz crushing

A dust removal device, fused silica technology, applied in the use of liquid separation agent, grain treatment, dispersed particle separation, etc., can solve the problems of easy dust drifting out again, poor dust removal effect, etc., to achieve good dust removal effect, convenient collection and utilization, The effect of preventing re-scattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

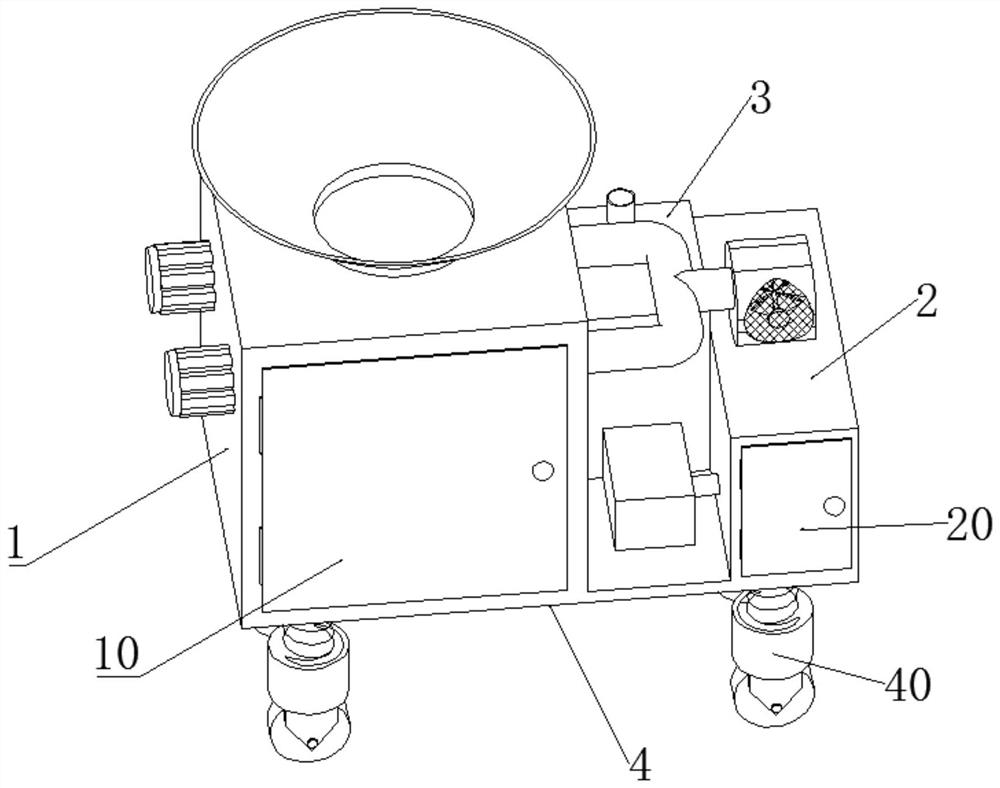

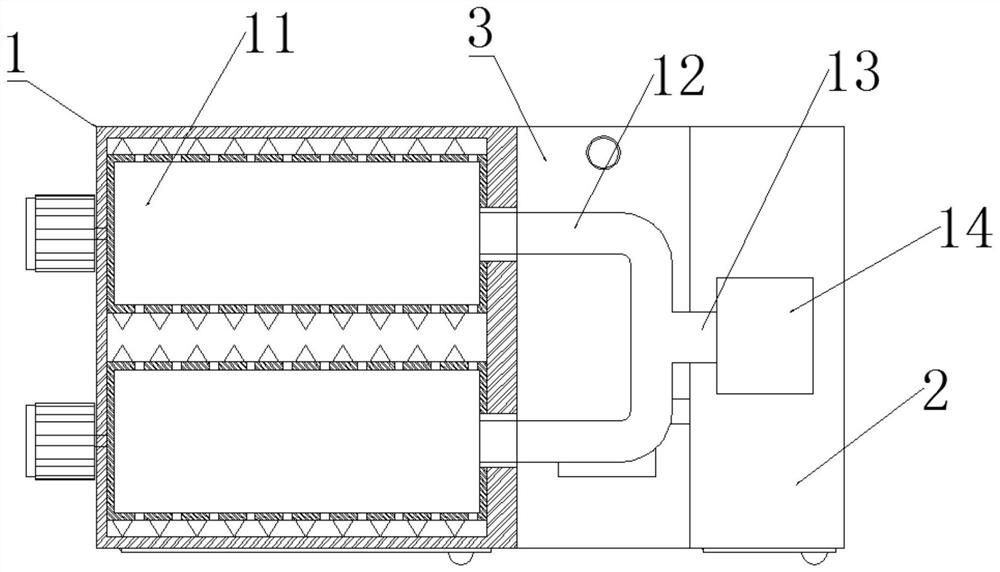

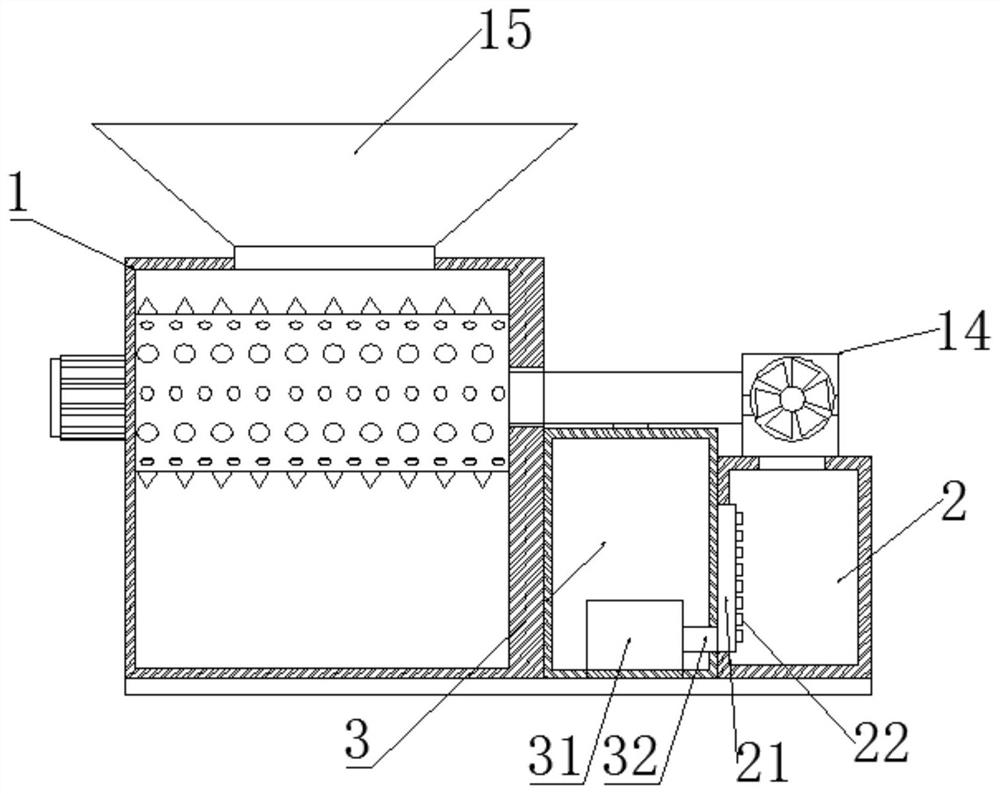

[0022] A dust removal device for crushing fused silica, in order to solve the problem that the dust removal effect of the current dust removal device for crushing fused silica is not good and the dust is easy to float out again, as a preferred embodiment, as figure 1 , figure 2 , image 3 and Figure 4 As shown, it includes a crushing box 1. Two crushing rollers 11 are installed in the interior of the crushing box 1. Two motors 111 are arranged on the outer wall of the crushing box 1. The output shaft of the motor 111 is connected to the crushing roller 11 through a coupling, and is output by the motor 111. The shaft drives the crushing roller 11 to rotate, and the two crushing rollers 11 rotate to crush the quartz. The outer wall of the crushing roller 11 is provided with a plurality of openings 112, and the end of the crushing roller 11 is connected with a gas pipe 12 through a bearing. A three-way pipe 13 is provided, and the end of the three-way pipe 13 is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com