Efficient comprehensive winnowing equipment with intelligent cleaning function

A kind of air separation equipment and high-efficiency technology, which is used in solid separation, separation of solids from solids by air flow, separation of dispersed particles, etc. It can solve problems such as poor economy, increase equipment investment, and increase the area of production lines to avoid problems. The effect of frequent shutdown and reducing labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In the process of realizing this application, the inventor found that: at present, the domestic environmental protection is becoming more and more strict, and the dust control on the construction site is also getting higher and higher, so most of the wind selections gradually start to take dust reduction measures or use dust removal equipment, but the use of dust removal equipment The cost is high, so it is urgent to find a more economical dust control method that can meet the dust control requirements of most usage scenarios. Based on this, the inventor has developed the present application.

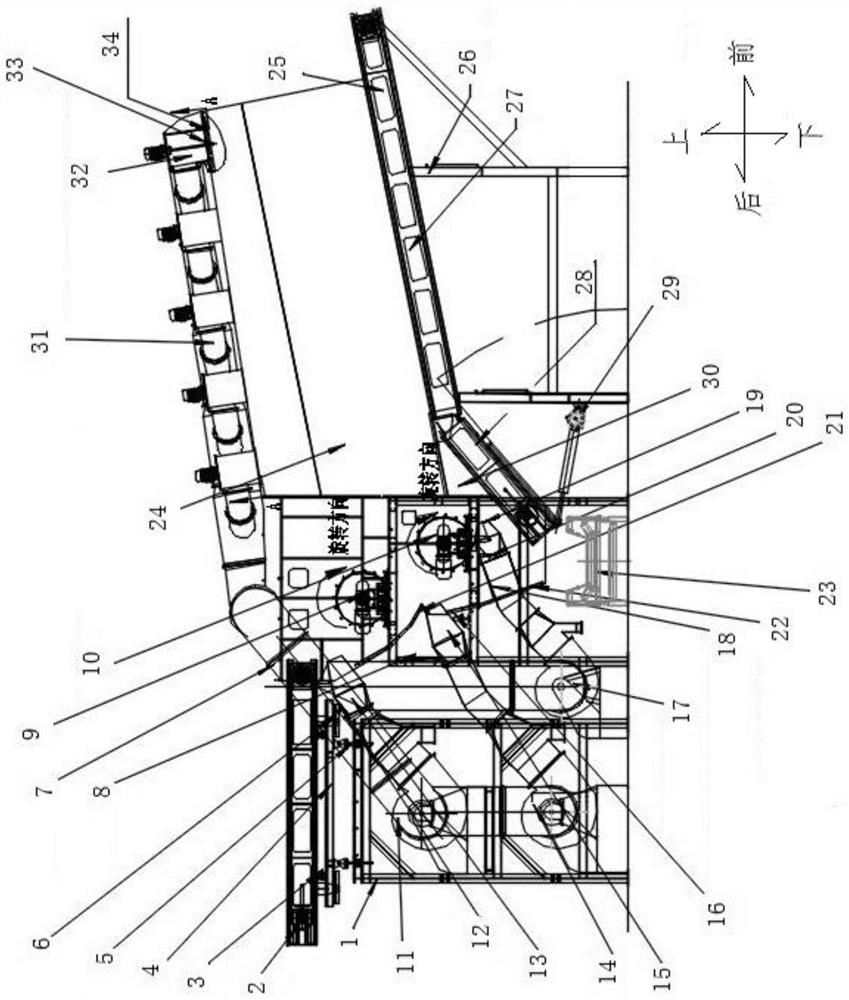

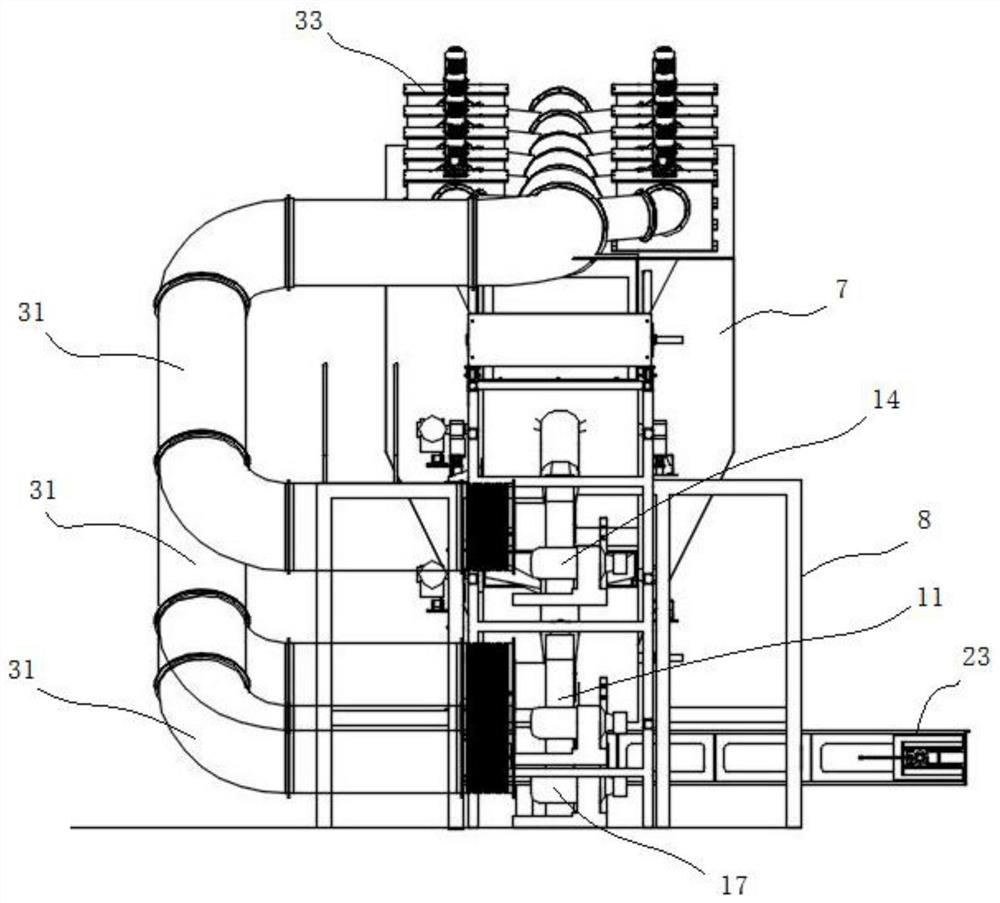

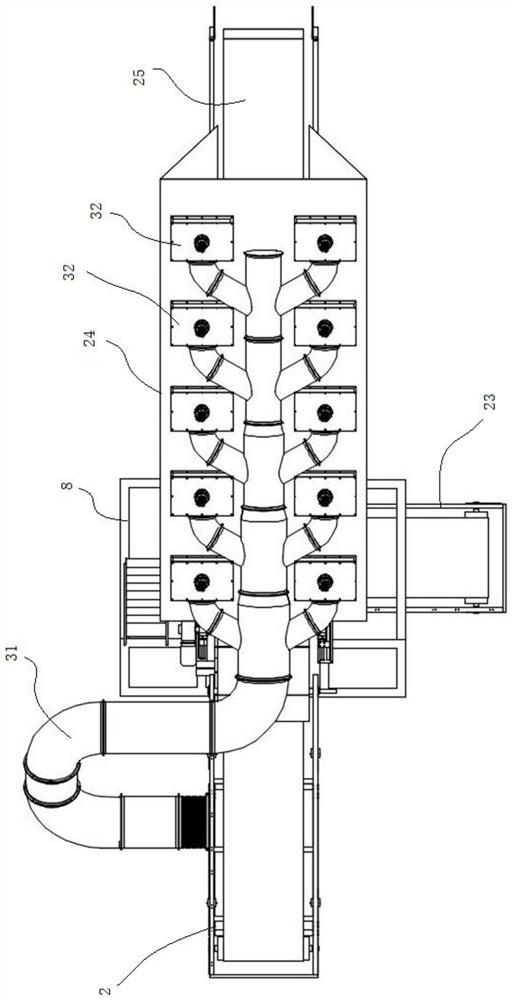

[0043] figure 1 It is a schematic front view of an efficient comprehensive winnowing equipment with intelligent cleaning function according to an embodiment of the present application. figure 2 yes figure 1 The schematic side view of the high-efficiency comprehensive winnowing equipment shown. image 3 yes figure 1 The schematic top view of the high-efficiency comprehensive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com