Wind turbine vane shaping device

A technology for wind power blades and trimming parts, which is applied in the field of trimming devices for wind power blades, can solve the problems of easily affecting the operation, the trimming angle cannot be adjusted, and the stability of the unit is affected, so as to achieve the effect of saving construction costs and protecting the blades.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

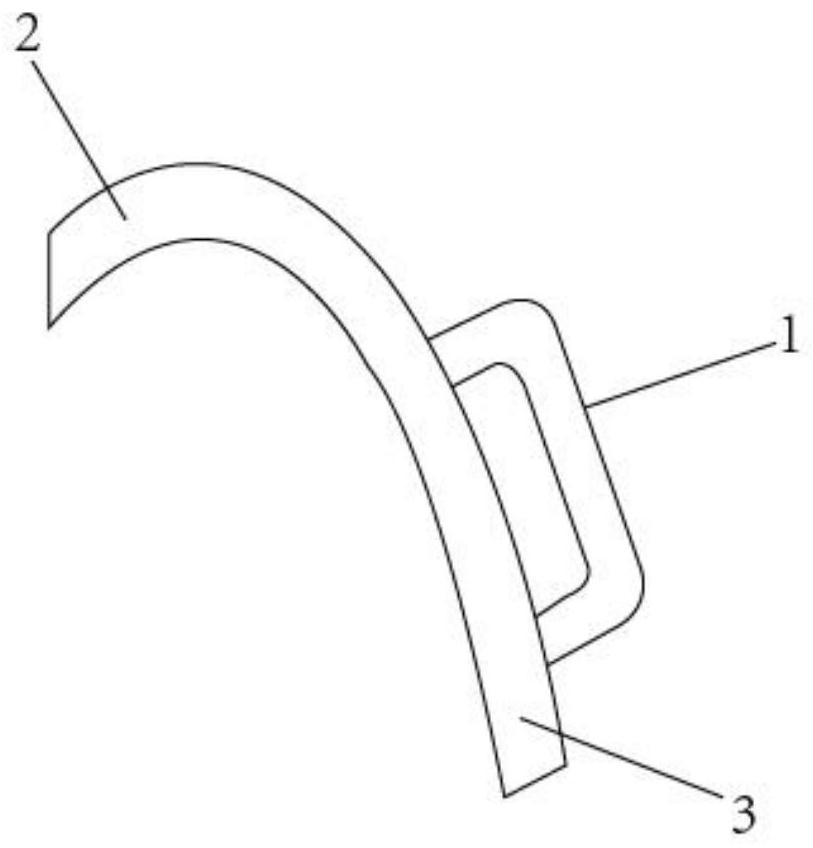

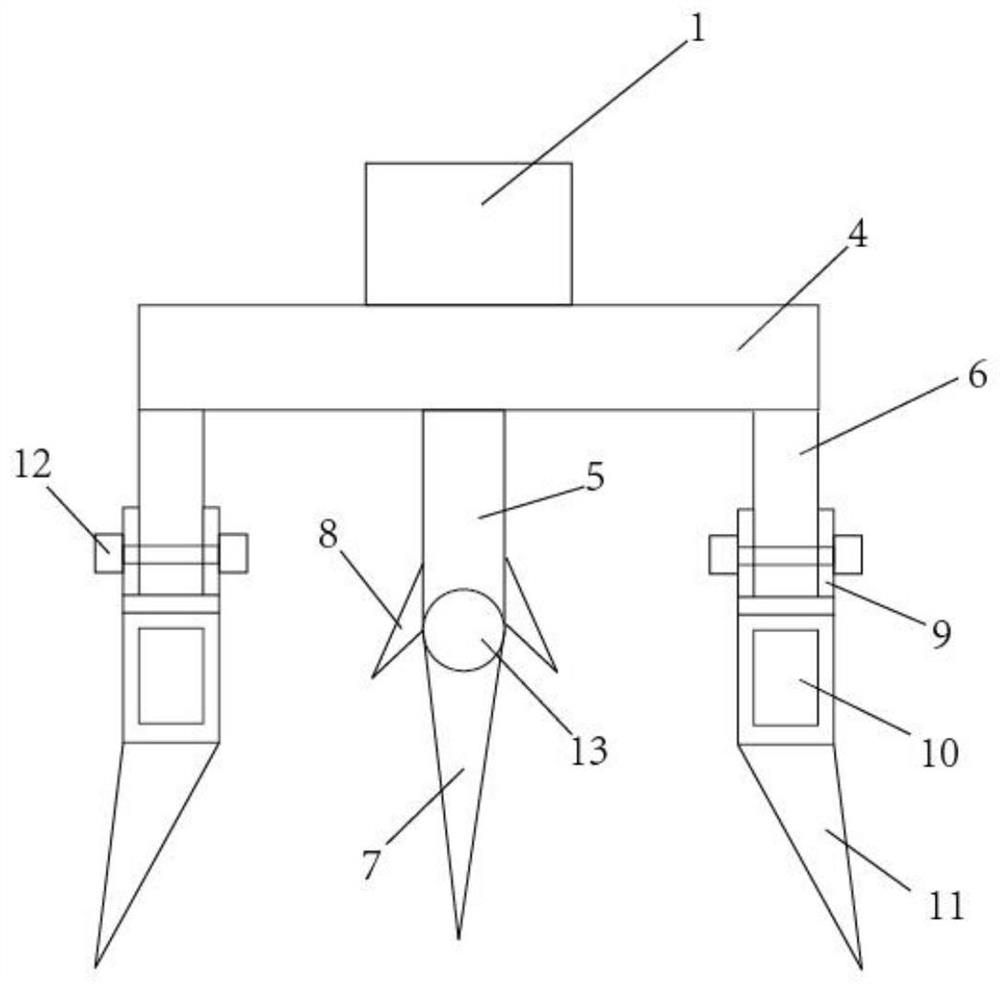

[0022] A device for trimming wind power blades, a handle, a first trimming part and a second trimming part, the first trimming part and the second trimming part are connected end to end, on the upper surface of the first trimming part and the second trimming part The handle is integrally set in the middle, the section structure of the first trimming part and the second trimming part is the same, both include the bottom plate, the blade mounting plate, the debris scraper mounting plate, the blade and the debris scraper, and the middle part is integrally set on the lower surface of the bottom plate The blade mounting plate is set, and the chip scraper mounting plate is respectively arranged on the lower surface of the bottom plate on both sides of the blade mounting plate, and the debris scraper is inserted into the chip scraper mounting plate, and a blade shaft is formed at the tail end of the blade mounting plate, and the blade The rotation is installed on the blade shaft, and ...

Embodiment 2

[0024] A device for trimming wind power blades, a handle, a first trimming part and a second trimming part, the first trimming part and the second trimming part are connected end to end, on the upper surface of the first trimming part and the second trimming part The handle is integrally set in the middle, the section structure of the first trimming part and the second trimming part is the same, both include the bottom plate, the blade mounting plate, the debris scraper mounting plate, the blade and the debris scraper, and the middle part is integrally set on the lower surface of the bottom plate The blade mounting plate is set, and the chip scraper mounting plate is respectively arranged on the lower surface of the bottom plate on both sides of the blade mounting plate, and the debris scraper is inserted into the chip scraper mounting plate, and a blade shaft is formed at the tail end of the blade mounting plate, and the blade The rotation is installed on the blade shaft, and ...

Embodiment 3

[0029] A device for trimming wind power blades, a handle, a first trimming part and a second trimming part, the first trimming part and the second trimming part are connected end to end, on the upper surface of the first trimming part and the second trimming part The handle is integrally set in the middle, the section structure of the first trimming part and the second trimming part is the same, both include the bottom plate, the blade mounting plate, the debris scraper mounting plate, the blade and the debris scraper, and the middle part is integrally set on the lower surface of the bottom plate The blade mounting plate is set, and the chip scraper mounting plate is respectively arranged on the lower surface of the bottom plate on both sides of the blade mounting plate, and the debris scraper is inserted into the chip scraper mounting plate, and a blade shaft is formed at the tail end of the blade mounting plate, and the blade The rotation is installed on the blade shaft, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com