Carbon molecular sieve raw material crushing system and process

A raw material pulverization and carbon molecular sieve technology, applied in grain processing and other directions, can solve the problems of large distribution range of phenolic resins, poor consistency, and difficulty in improving the adsorption capacity of carbon molecular sieves, etc., to achieve a narrowed diameter distribution range, a small distribution range, and guaranteed crushing. thorough effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

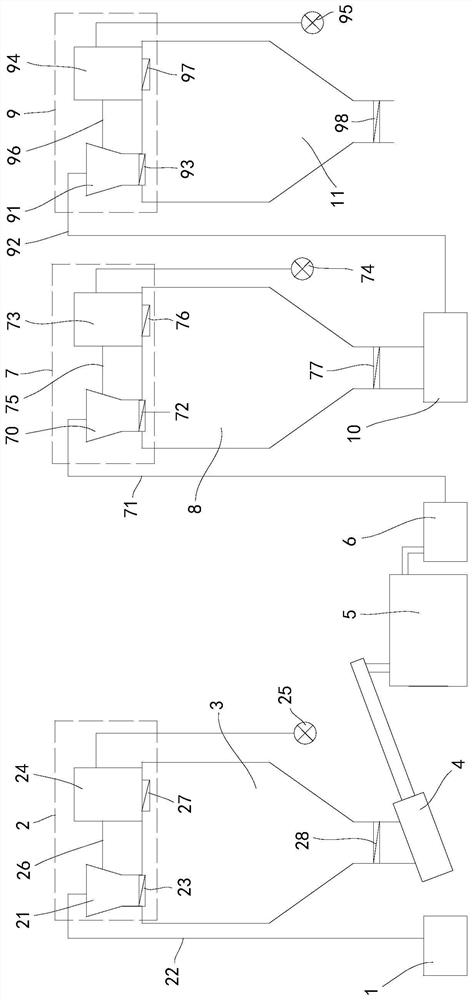

[0020] Example 1. Carbon molecular sieve raw material crushing system, such as figure 1 As shown, the coarse grinding pulverizer 1 and the coarse grinding pulverizer 1 are connected to the first feed bin 3 through the first transmission mechanism 2 of one-way feeding, and the first feed bin 3 is connected to the heating furnace 5 through the conveyor 4, and the heating furnace 5 The furnace temperature is 400-500°C, the discharge end of the heating furnace 5 is provided with a fine grinder 6, and the fine grinder 6 is connected to the second feed bin 8 through the second transmission mechanism 7 of one-way feeding, and the second feed bin 8 The discharge end is provided with a fine grinding pulverizer 10, and the fine grinding pulverizer 10 is connected to the third silo 11 through the third transmission mechanism 9 of one-way feeding.

[0021] The first transmission mechanism 2 includes a first collecting hopper 21 arranged on the top of the first silo 3, the first collectin...

Embodiment 2

[0032] Example 2. The difference from Embodiment 1 is that the system does not have the third shut-off fan 28 and the sixth shut-off fan 77 .

[0033] The phenolic resin powder of Example 1 is compared with the phenolic resin powder of Example 2, and the following table 1 results are obtained.

[0034] Example 1 Example 2 Overall diameter range (microns) 1-5 1-7 1-2 micron diameter range content 4% 3% 2-3 micron diameter content 79% 64% 3-4 micron diameter content 12% 17% 4-5 micron diameter content 5% 9% 5-7 micron diameter content 0 7%

[0035] Table 1

[0036] As can be seen from Table 1, the existence of the third fan 28 and the sixth fan 77 makes the phenolic resin pulverized finer, and the distribution range on different diameter ranges is small, and mainly concentrated in 2-3 microns, consistent Sex is better.

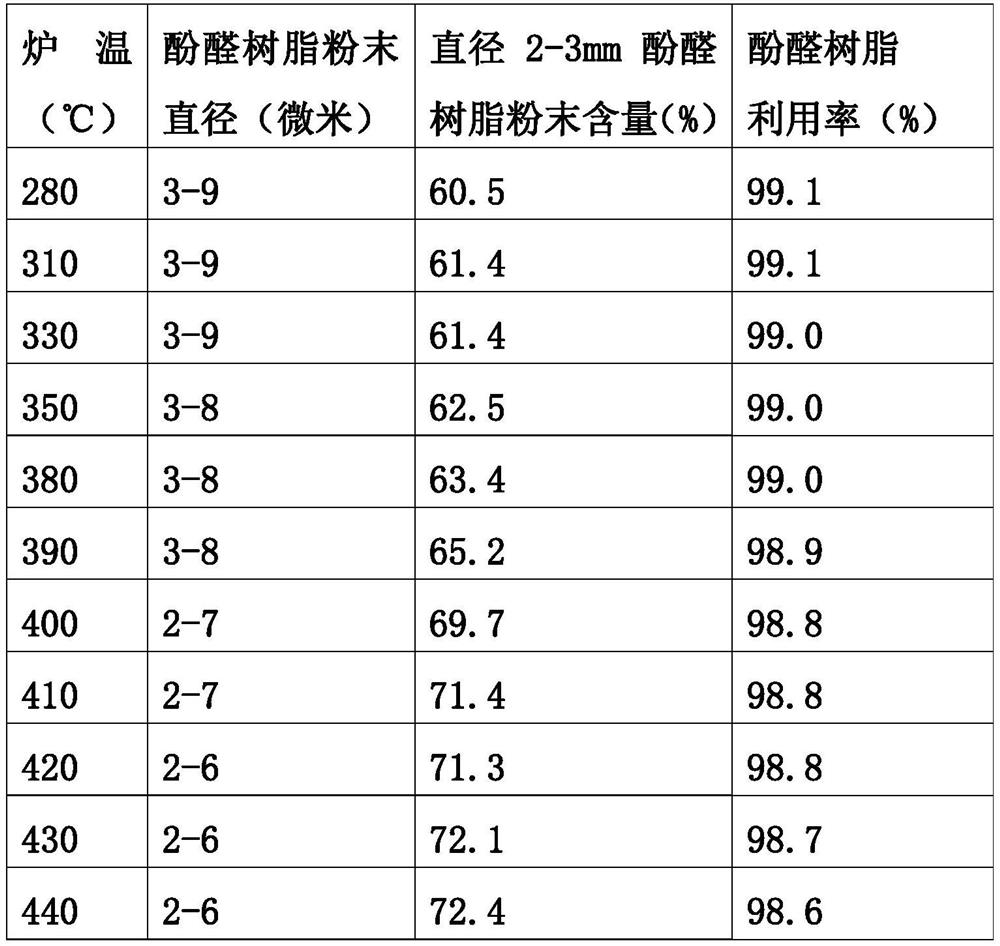

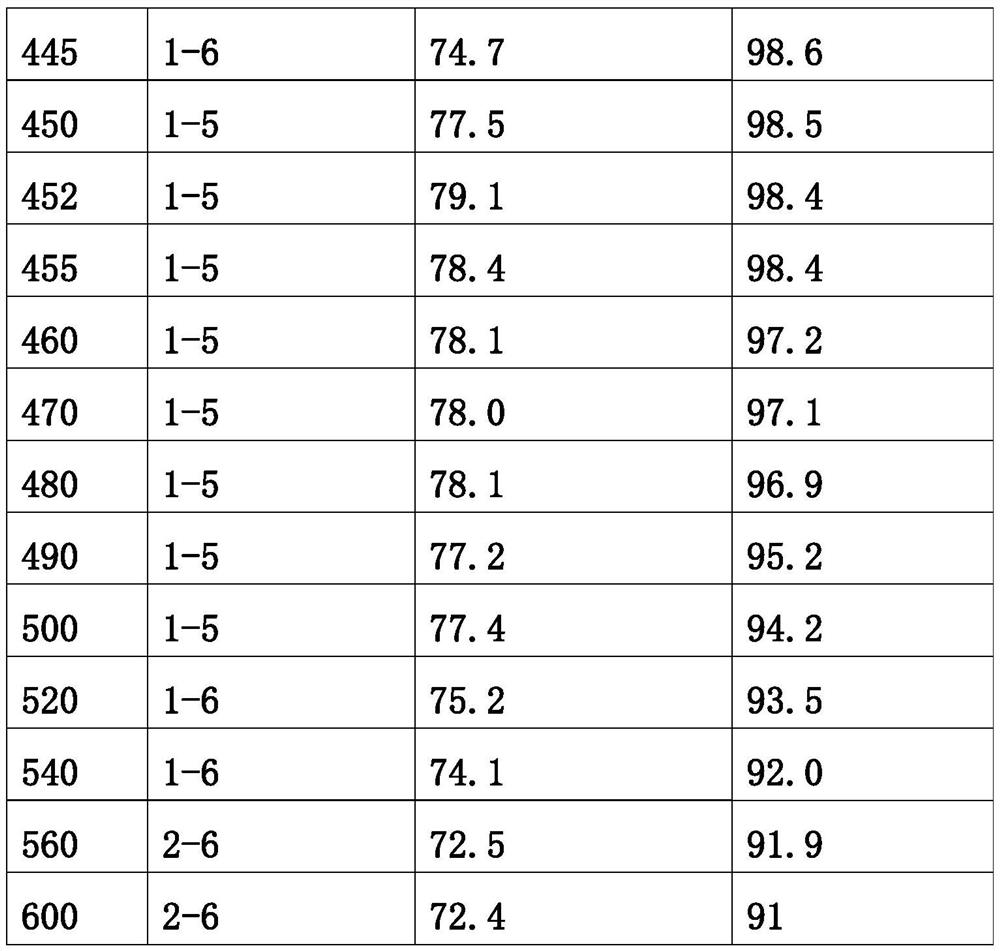

[0037] Based on Example 1, by adjusting the temperature of the furnace, the contents of Table 2 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com