Hook cup separating, overturning and conveying device

A technology of conveying device and material distribution mechanism, which is applied in the direction of conveyor control device, conveyor, vibrating conveyor, etc., can solve the problems of easily scratched hook cup, high labor cost, loss, etc., to avoid manual damage to products, Save labor costs and ensure the effect of yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

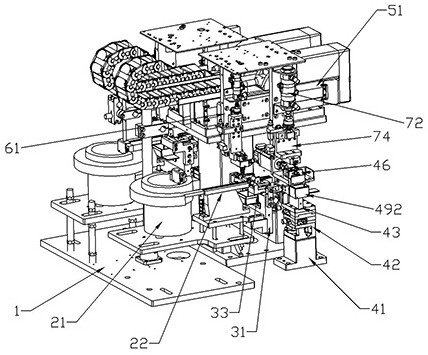

[0022] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 As shown, the present invention includes a frame 1, and the frame is respectively provided with a feeding mechanism, a material distributing mechanism, a turning mechanism and a grabbing and carrying mechanism, and the feeding mechanism is connected with the material distributing mechanism, and the The material distributing mechanism corresponds to the turning mechanism, and the grasping and carrying mechanism is adapted to move above the material dividing mechanism and the turning mechanism.

[0023] The feeding mechanism includes a vibrating feeding tray 21, a linear vibrating feeding channel 22 and a feeding camera, the feeding end of the linear vibrating feeding channel 22 is connected with the discharging end of the vibrating feeding tray 21, The feeding camera is placed above the linear vibrating feeding channel 22 .

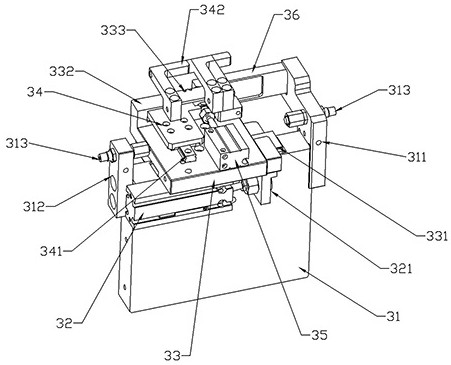

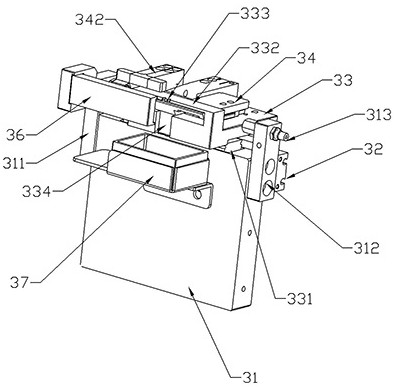

[0024] The distribution mechanism includes a first moun...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap