Chain plate leveling device for chain processing

A chain plate and leveling technology, applied in the field of machinery, can solve problems such as hidden safety hazards, low efficiency, and inability to continue processing, and achieve the effect of improving work speed, increasing safety, and saving time for adjusting chain plates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments:

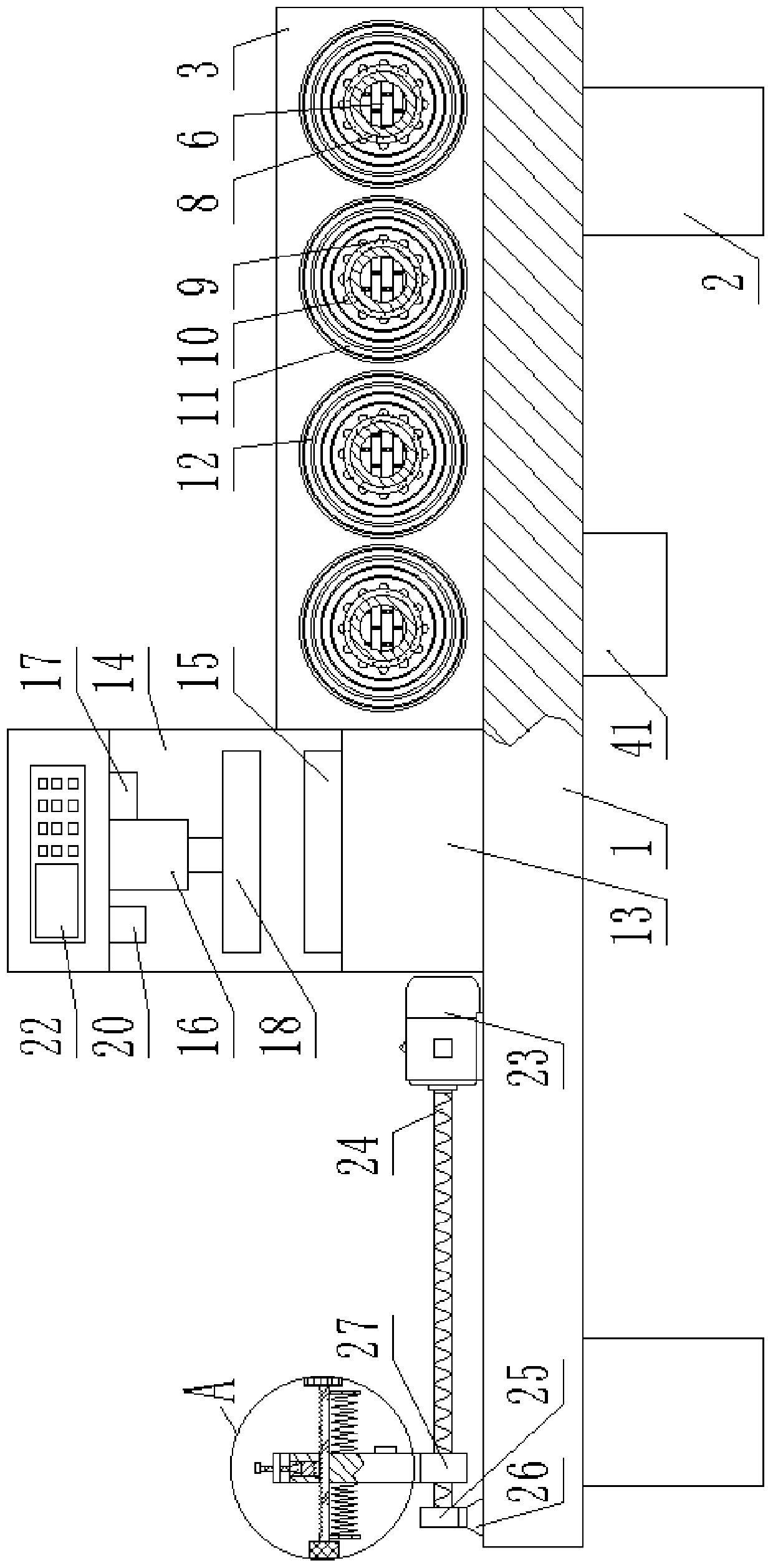

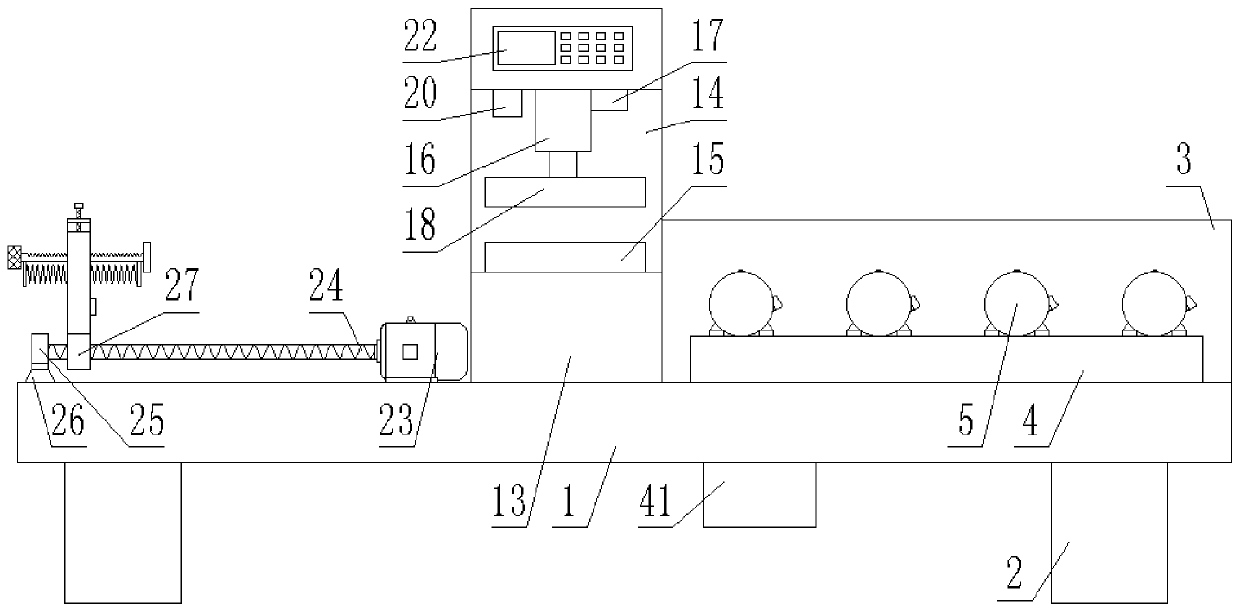

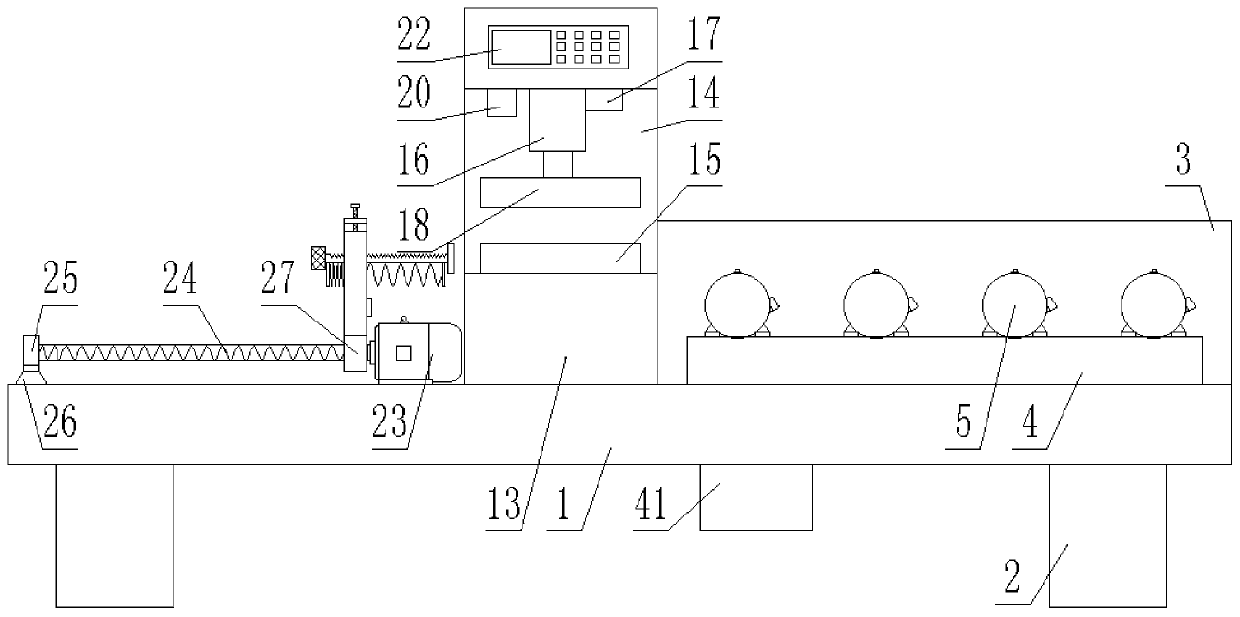

[0032] Such as Figure 1-Figure 8 As shown, a chain plate leveling device for chain processing includes a workbench 1. A plurality of support columns 2 are uniformly fixed on the bottom surface of the workbench 1, and the support columns 2 and the workbench 1 are fixed by welding , The top surface of the workbench 1 is symmetrically fixed with a baffle 3, the top surface of the workbench 1 is fixed with a support seat 4, the support seat 4 and the baffle 3 are parallel to each other, the top of the support seat 4 A plurality of first motors 5 are uniformly arranged on the surface, and the first motor 5 and the supporting base 4 are fixed by bolts, the driving end of the first motor 5 passes through the baffle 3, and the driving end of the first motor 5 is fixedly connected with The shaft 6 has a flange bearing 7 installed at both ends of the shaft 6...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap