Fork type loading and unloading vehicle head

A technology of loading and unloading trucks and machine heads, applied in loading/unloading, conveyors, conveyor objects, etc., can solve the problems of in-position palletizing interference, goods are difficult to slide, and goods cannot be palletized in place, etc., to improve accuracy stability, improved stability and security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

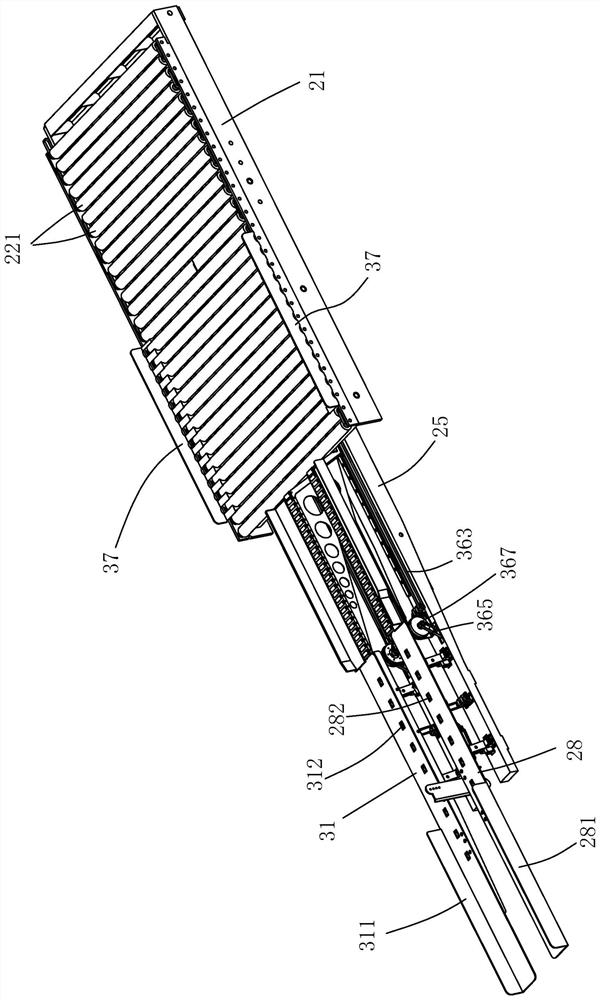

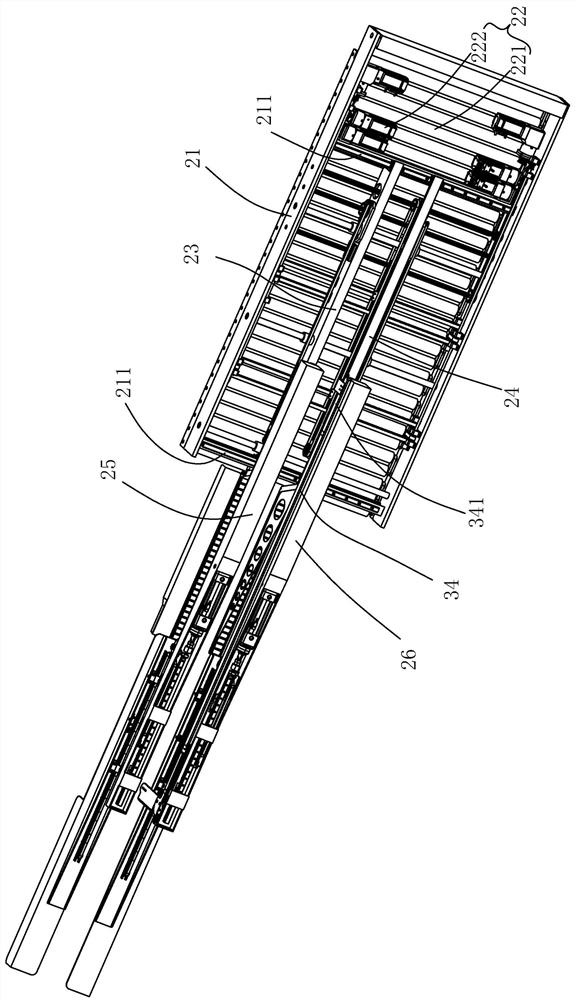

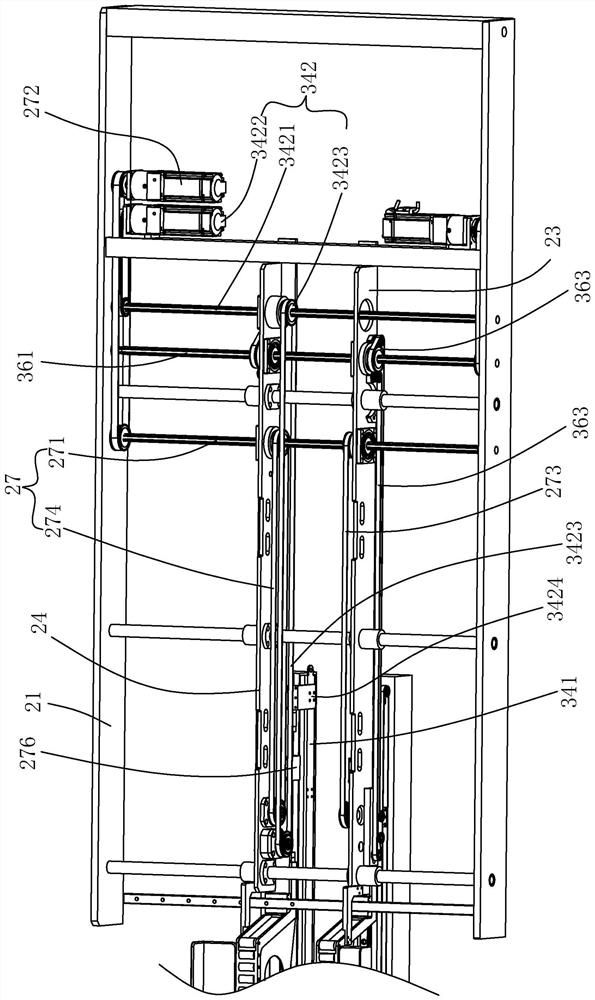

[0029] Such as Figure 1 to Figure 7As shown, the head of a forklift truck in this embodiment includes: a frame 21, on which a cargo conveying assembly 22 for conveying goods is arranged, on which a left Transversely moving beam 23 and right laterally moving beam 24, described left laterally moving beam 23 and right laterally moving beam 24 are parallel to each other, described left laterally moving beam 23 is slidably connected with left longitudinal reference seat 25, described right A right longitudinal reference seat 26 is slidably connected to the lateral moving beam 24, and the left longitudinal reference seat 25 and the right longitudinal reference seat 26 are parallel to each other. The first drive assembly 27 for the synchronous movement of the reference seat 26; the left fork arm 28 is connected to the left longitudinal reference seat 25, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com