Azo dye compound with high washing fastness, preparation method and application

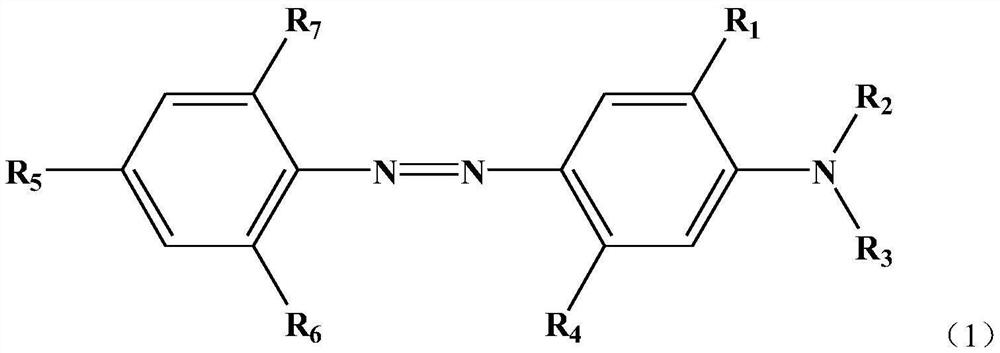

A technology of azo dyes and compounds, applied in azo dyes, monoazo dyes, organic dyes, etc., can solve the problems of high concentration of toxic and harmful substances, low color intensity of original dyes, small extinction coefficient of molar molecules, etc. Good washing fastness, excellent washing fastness, bright color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

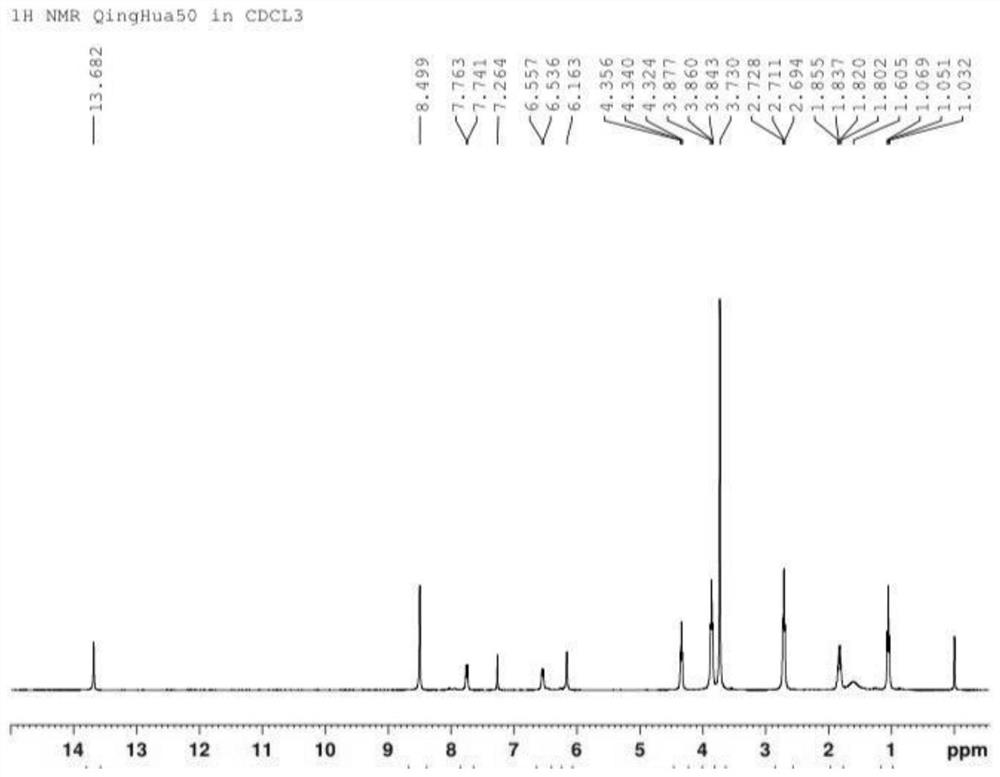

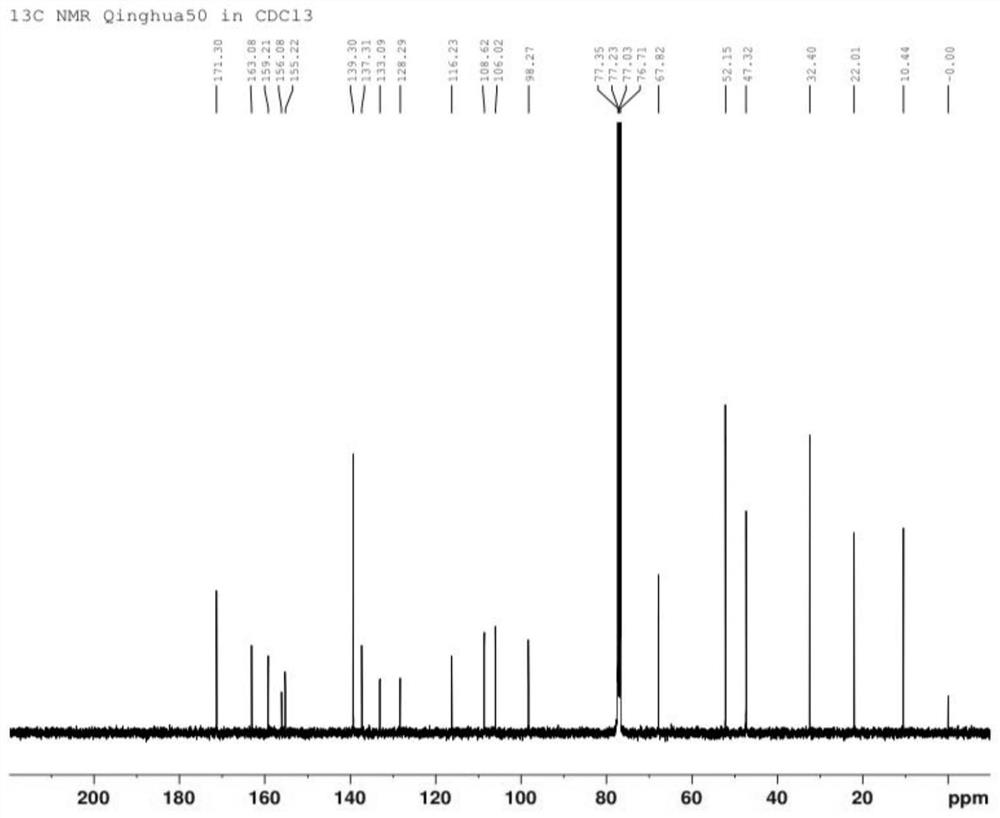

Image

Examples

Embodiment 1

[0069] Add 180G of sulfuric acid and 56G of nitrosylsulfuric acid into a 250ml three-necked flask, cool down to 0-5°C in an ice bath under stirring, add 58.6G of compound (A-1) in portions for 1 hour, and keep at this temperature Stir for 3 hours.

[0070]

[0071] After the reaction is completed, a diazo solution is obtained; at a temperature of 5-9°C, drop the diazo solution into a mixture containing 50ML of sulfuric acid, 800G of ice water and 56.48G of compound (B-1) within 1 hour in, stirred for 3 hours, filtered, washed with water and dried to obtain the azo dye compound (X 1 -1) 111.15G.

[0072]

[0073] The dye is used for dyeing polyester fiber in red light orange. λmax (nm) = 445nm.

Embodiment 2

[0075] According to the preparation method of embodiment 1 synthetic dyestuff (X 1 -2), the dye is used for polyester fiber dyeing red light orange. λmax (nm) = 449.1 nm.

[0076]

Embodiment 3

[0078] According to the preparation method of embodiment 1 synthetic dyestuff (X 1 -3), the dye is used for dyeing polyester fiber to get golden yellow. λmax (nm) = 445nm.

[0079]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com