Garbage gasification power generation equipment

A technology for power generation equipment and garbage, which is applied in special forms of dry distillation, petroleum industry, coke oven, etc., can solve the problems of harmful gas leakage, pollution of external air quality, and dispersion, so as to ensure the effect of force bearing, improve the effect of dispersion, The effect of increasing the spread area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0039] as attached figure 1 to attach Figure 9 Shown:

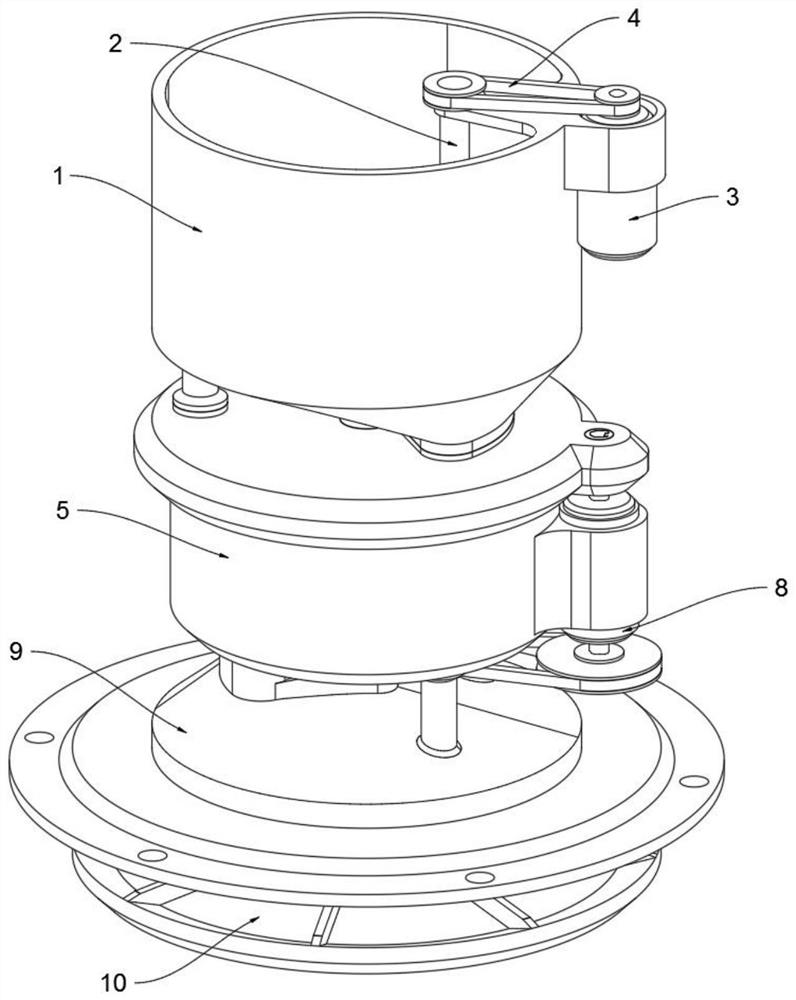

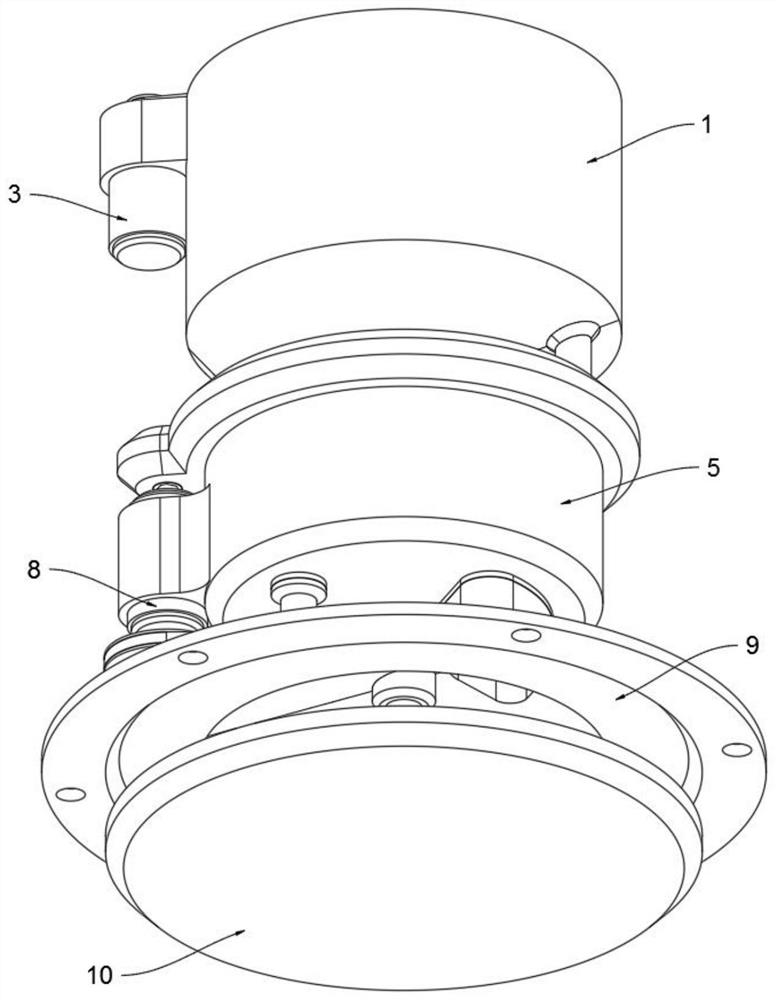

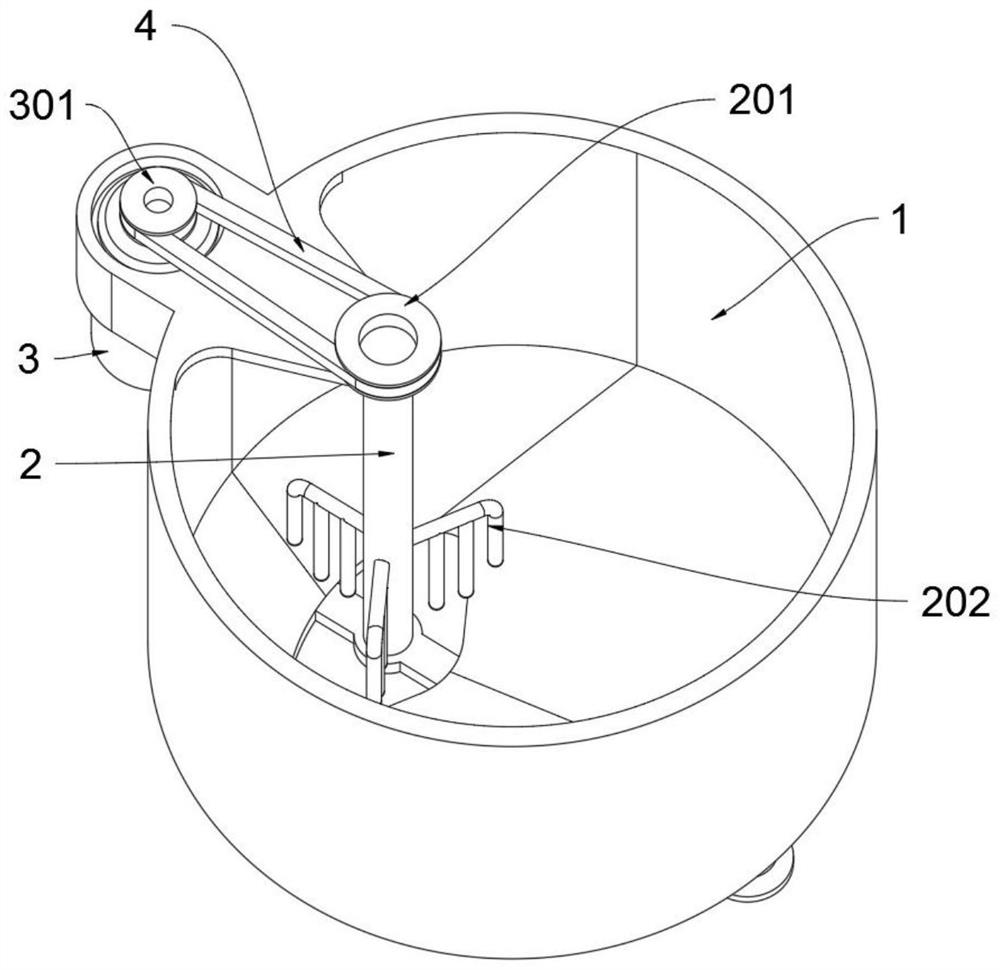

[0040] The present invention provides a garbage gasification power generation equipment, including a hopper 1, a motor B8 and a blanking cover 9; a rotating shaft 2 is installed inside the hopper 1, and the rotating shaft 2 is connected with a belt 4, and the hopper 1 is fixedly installed on the top side of the main body 5; the main body 5 includes: feed port 501 and discharge port 502; feed port 501 is located at the right end of the top of the main body 5, the bottom of the hopper 1 is connected to the feed port 501; discharge port 502 is located at the left end of the bottom of the main body 5, and the bottom of the blanking cover 9 It communicates with the discharge port 502, and the inside of the main body 5 is rotatably connected with the feeding part 6. The inside of the feeding part 6 is provided with three material cavities 601 in a circular shape. The material port 502 is connected. When the top of the materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com