Automatic oxygen introduction type auxiliary fermentation mechanism for bio-based material research

An auxiliary fermentation and bio-based technology, which is applied in the direction of specific-purpose bioreactor/fermenter, bioreactor/fermenter combination, biomass post-treatment, etc., can solve the problem of low practicability, affecting fermentation efficiency, and low degree of automation and other problems, to achieve the effect of high practicability, convenient operation and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

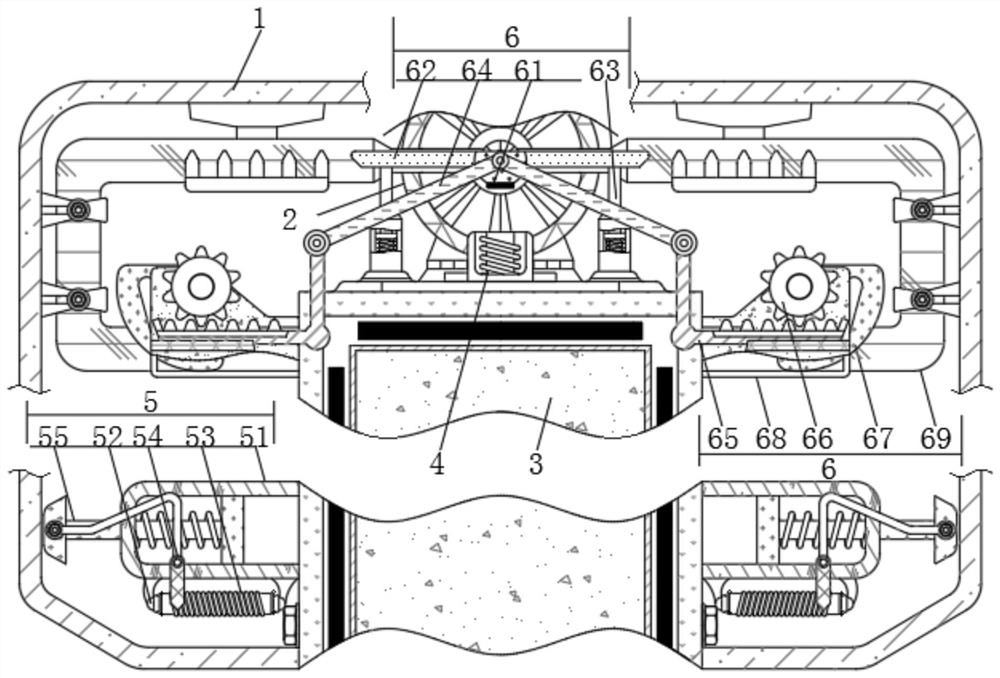

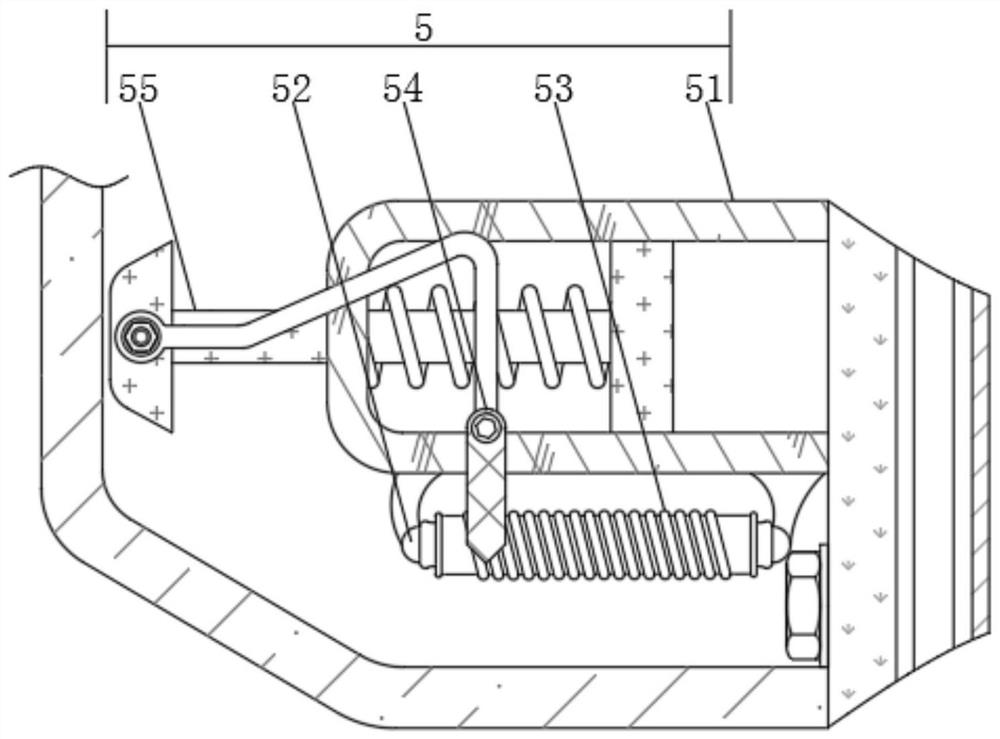

[0025] see figure 1 and image 3 , an automatic aerobic auxiliary fermentation mechanism for bio-based material research, including a detection mechanism 5 for monitoring the amount of oxygen, the detection mechanism 5 includes a side pipe 51, the bottom of the side pipe 51 is fixedly connected with an insulating pipe 52, and the insulation The outside of the tube 52 is wound with a resistance coil 53, the surface of the resistance coil 53 is slidably connected with a metal slide 54, and the inside of the side tube 51 is clamped with a piston 55. There are two side tubes 51 with the same specification, and the metal slide 54 is Copper material, its outer side is fixedly connected with a connecting rod, and the connecting rod is made of insulating material. Initially, the metal slide 54 is located at the end of the insulating tube 52, and the number of resistance coils 53 connected to the circuit is the largest, that is, the resistance of the circuit is the largest, and the cur...

Embodiment 2

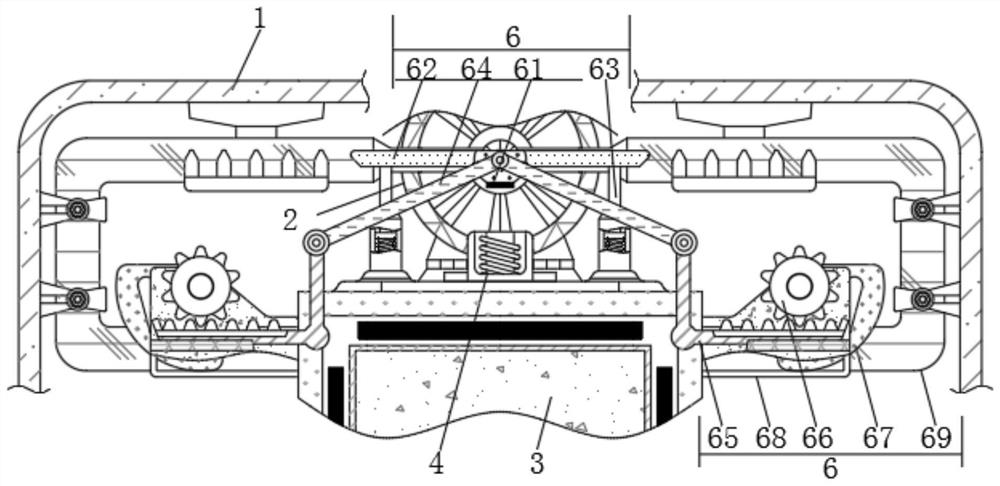

[0028] see Figure 1-2 , an automatic aeration type auxiliary fermentation mechanism for bio-based material research, also includes an oxygen supply mechanism 6 for supplementing oxygen, the oxygen supply mechanism 6 includes a metal block 61, and the top of the metal block 61 is fixedly connected with a connecting frame 62, the bottom of connecting frame 62 is provided with sleeve rod 63, and the surface of connecting frame 62 is connected with rotary rod 64, and the side of rotating rod 64 away from connecting frame 62 is slidingly connected with moving rod 65, and the top of moving rod 65 is connected with The gear 66 is fixedly connected to the outside of the gear 66 with a pressing plate 67 , the outer side of the pressing plate 67 is provided with a clamping frame 68 , and the inside of the clamping frame 68 is clamped with a ventilation pipe 69 . There are two sleeve rods 63 with the same specifications. The sleeve rod 63 is composed of an inner rod and an outer tube. ...

Embodiment 3

[0031] see Figure 1-3, an automatic aerobic auxiliary fermentation mechanism for bio-based material research, including a detection mechanism 5 for monitoring the amount of oxygen, the detection mechanism 5 includes a side pipe 51, the bottom of the side pipe 51 is fixedly connected with an insulating pipe 52, and the insulation The outside of the tube 52 is wound with a resistance coil 53, the surface of the resistance coil 53 is slidably connected with a metal slide 54, and the inside of the side tube 51 is clamped with a piston 55. There are two side tubes 51 with the same specification, and the metal slide 54 is Copper material, its outer side is fixedly connected with a connecting rod, and the connecting rod is made of insulating material. Initially, the metal slide 54 is located at the end of the insulating tube 52, and the number of resistance coils 53 connected to the circuit is the largest, that is, the resistance of the circuit is the largest, and the current The mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com