Prefabricated assembled wharf structure capable of being rapidly formed

A prefabricated assembly and wharf technology, applied in water conservancy projects, sea area engineering, climate change adaptation, etc., to achieve the effect of reducing wave force, less types and quantities, and greater self-stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing by specific embodiment:

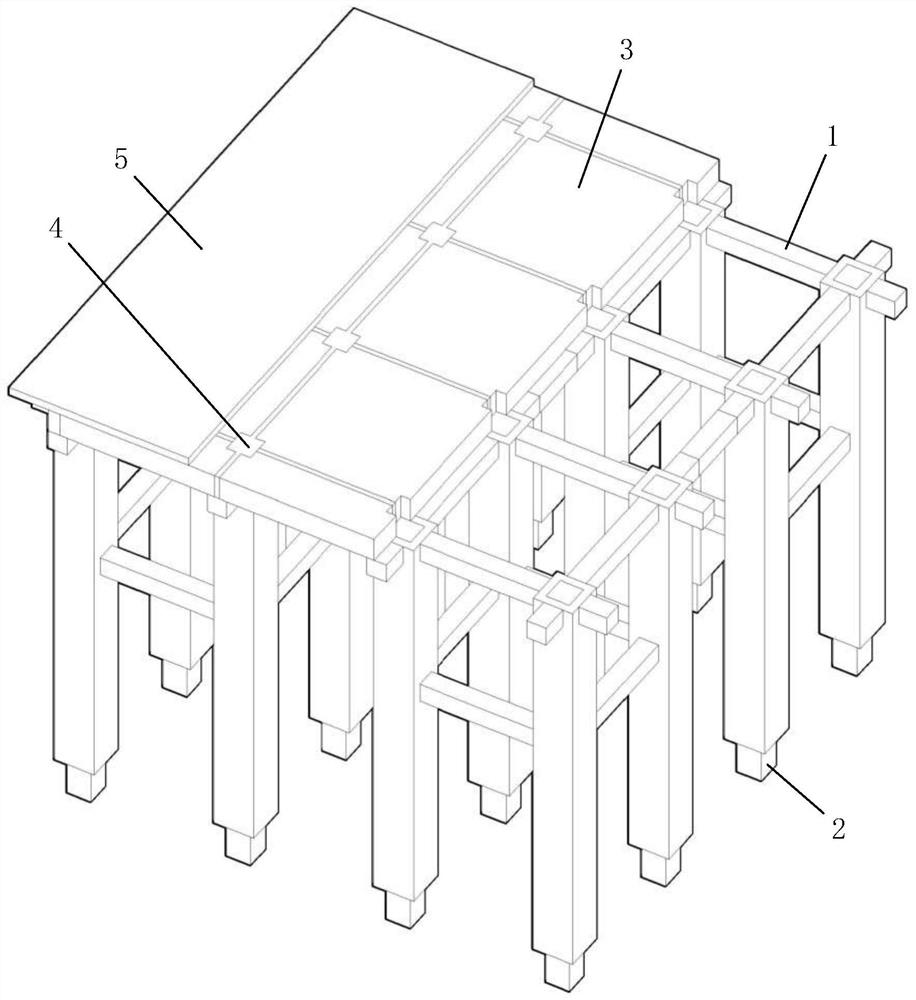

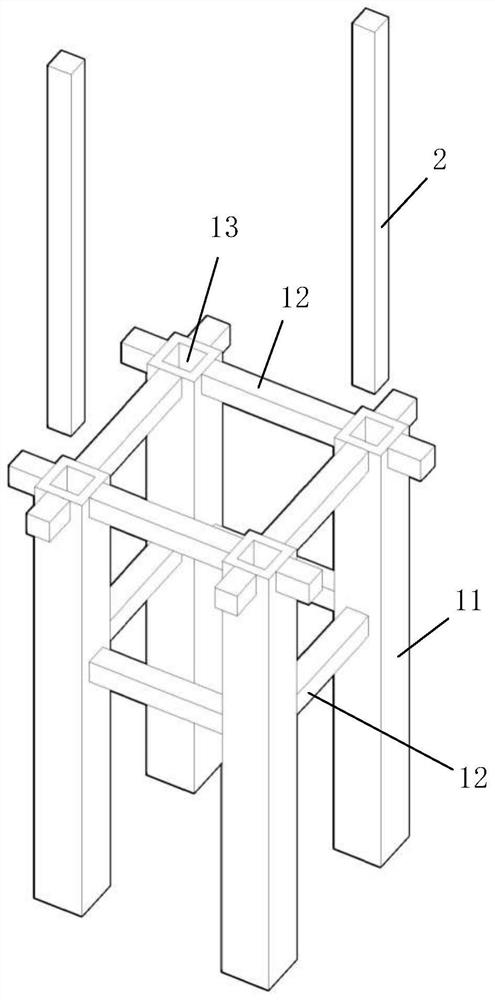

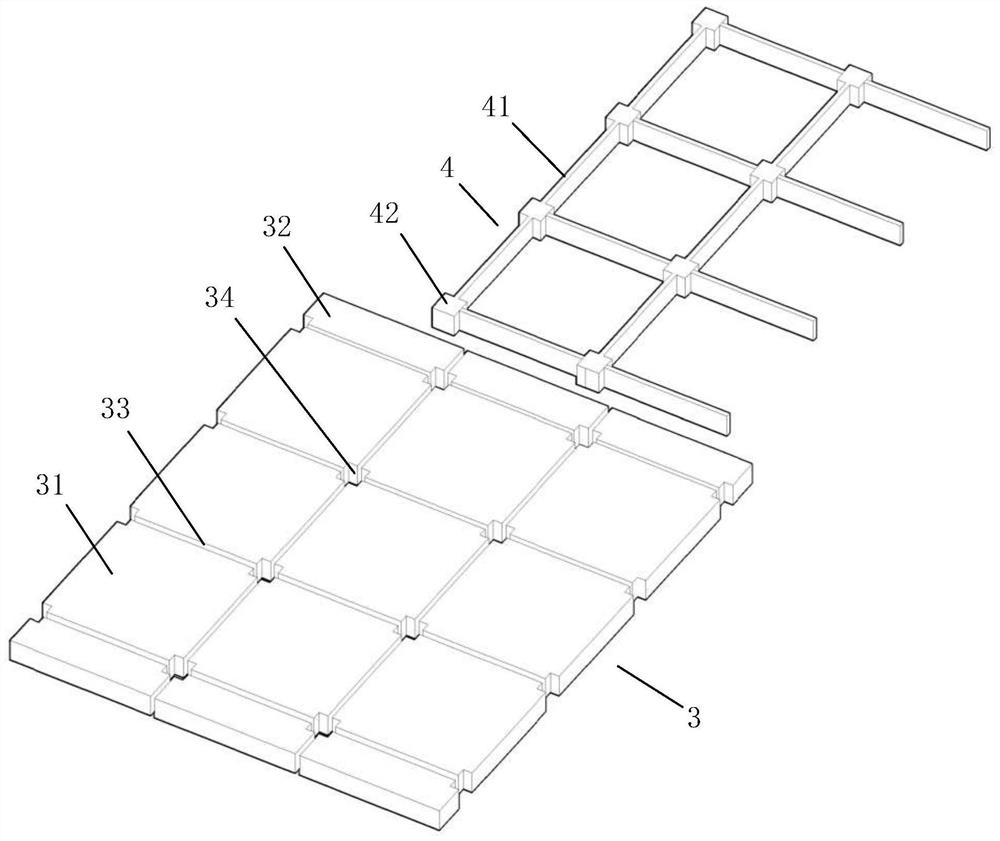

[0024] In this example, refer to figure 1 , figure 2 and image 3 , the rapidly formed prefabricated assembled wharf structure includes a prefabricated frame 1 and a prefabricated panel 3, the prefabricated frame 1 includes hollow columns 11, the hollow columns 11 are connected by connecting beams 12, and the hollow columns 11 are provided with Down through the cast-in-place hole 13 of the hollow column 11; the cast-in-place core column 2 is formed by pouring cast-in-place concrete into the cast-in-place hole 13, and the bottom end of the cast-in-place core column 2 passes through the bottom end of the hollow column 11 and is embedded in the foundation , while the bottom end of the hollow column 11 is supported on the foundation; several independent prefabricated main panels 31 and prefabricated side panels 32 are spliced on the prefabricated fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com