A real-time acid concentration control method for acid fracturing in oil and gas fields

A technology of acid fracturing and acid concentration, which is applied in chemical instruments and methods, mixing methods, earthwork drilling and mining, etc. It can solve the problem of insufficient supply of acid liquid, consumption of effective seepage channels by acid liquid, failure to ensure effective acid liquid discharge, etc. problems, to achieve the effect of reducing the number of acid tanks, adapting to environmental protection, and increasing the conductivity of cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

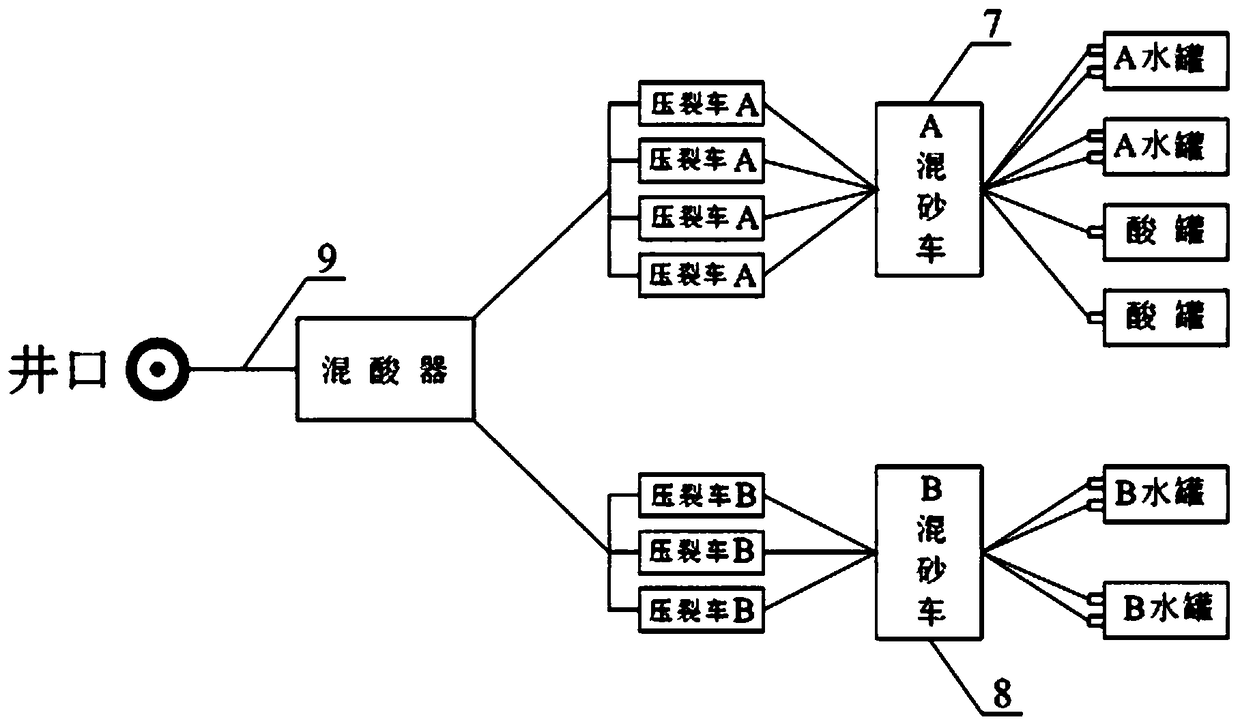

[0026] This implementation provides a real-time acid concentration control method for acid fracturing in oil and gas fields, such as figure 2 shown, including the following steps:

[0027] 1) Connect the A sand mixing vehicle 7 with the acid tank and the A water tank, and the B sand mixing vehicle 8 with the B water tank;

[0028] 2) Connect the acid inlet 5 of the acid mixer to the outlet pipeline of fracturing truck A that alternately pumps water-repelling and slick acid, and the inlet pipeline of fracturing truck A is connected to sand mixer A 7;

[0029] 3) Connect the liquid inlet 4 of the acid mixer to the liquid outlet pipeline of the fracturing vehicle B pumping slick acid, and connect the liquid inlet pipeline of the fracturing vehicle B to the sand mixing vehicle 8 of B;

[0030] 4) Connect the liquid outlet 3 of the acid mixer with the wellhead pipeline 9;

[0031] 5) When injecting slick acid in the high-pressure acid injection stage of acid fracturing construct...

Embodiment 2

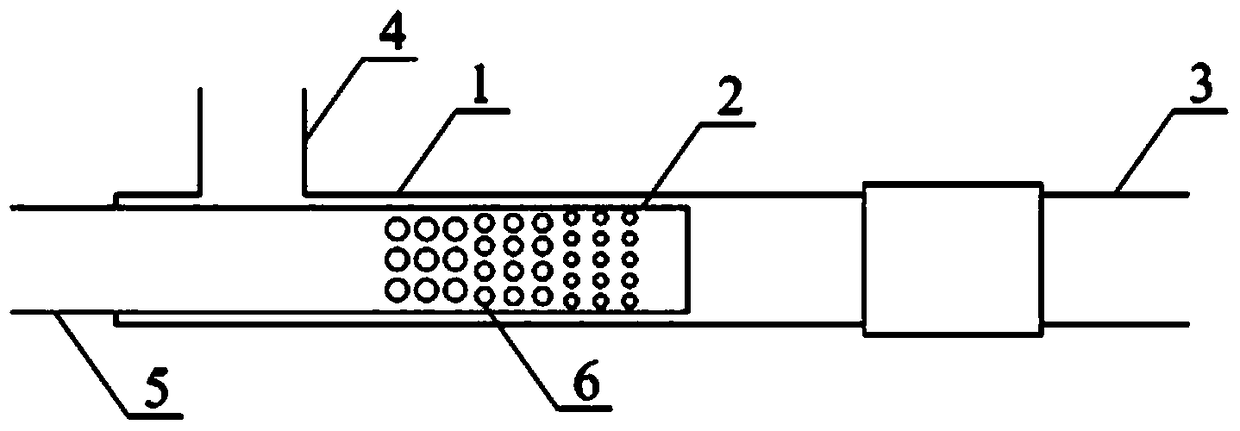

[0035] On the basis of Example 1, such as figure 1 As shown, the acid mixer is composed of an outer cylinder 1, an inner cylinder 2, and a liquid outlet 3; the outer cylinder 1 is provided with a liquid inlet 4, the inner cylinder 2 is fixed inside the outer cylinder 1, and the liquid outlet 3 is connected to the outer cylinder 1 end, the end of the inner cylinder 2 is blocked, the front end of the inner cylinder 2 is the acid inlet 5, along the axial direction of the inner cylinder 2, there are liquid outlet holes 6 arranged in sequence from the acid inlet 5 to the end. The inner cavity of the outer cylinder 1 and the liquid outlet 3, the inner cavity and the outer side of the inner cylinder 2 are all sprayed with polytetrafluoroethylene. The diameter of the liquid outlet hole 6 gradually decreases along the axial direction of the inner cylinder 2 .

[0036] The invention utilizes an acid mixer to realize uniform mixing of water resistance and slick acid; the inner cavity of...

Embodiment 3

[0038] On the basis of Example 1 and Example 2, this example uses the real-time acid concentration control method for acid fracturing in oil and gas fields of the present invention to treat the 3390.6m-3410.3m well of Sudong 38-25C2 in Changqing Oilfield. The effective thickness of the interval is 16.5m, and concentrated perforation is carried out near the upper part of the reservoir at 3391.0m to 3395.0m. Design water resistance reduction 71.3m 3 , slick acid 197.3m 3 , Steering acid 50.0m 3 . In the implementation plan, slick acid is used as the pre-fracture-making liquid; the resistance-reducing water etches the main cracks and expands the micro-cracks to form effective seepage channels; the diverting acid increases the viscosity and temporarily plugs the cracks formed in the previous stage, which is conducive to the formation of new cracks by the subsequent liquid .

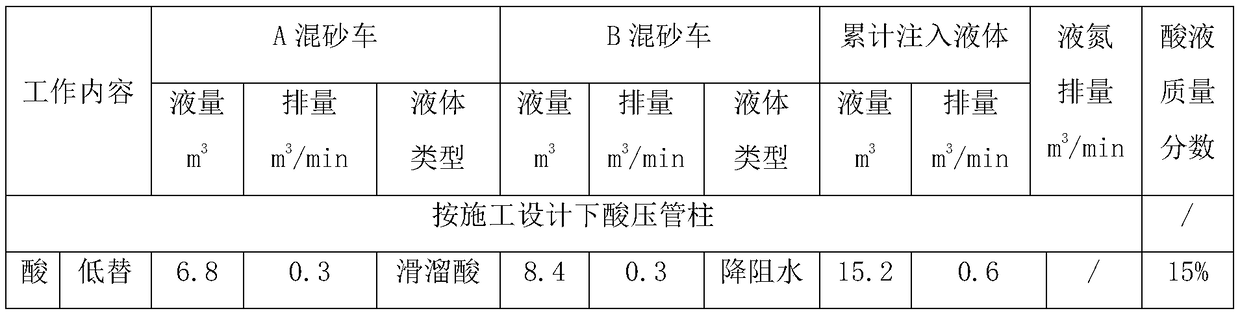

[0039] During acid fracturing construction, A sand mixing vehicle 7 is connected to all acid tanks and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com