Attenuation type high-uniformity phase shift photomask blank and preparation method thereof

An attenuation-type, photomask technology, applied in the field of photomasks, can solve problems such as no clear directivity of hydrofluoric acid resistance, no quality improvement of light interference, and difficulty in forming photolithographic patterns, etc., to achieve Good display effect, good overall interaction, high uniformity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The present invention also provides a method for preparing an attenuated highly uniform phase-shift photomask blank described in the above technical solution, comprising the following steps:

[0046] a) Pretreating the glass substrate to obtain a treated glass substrate;

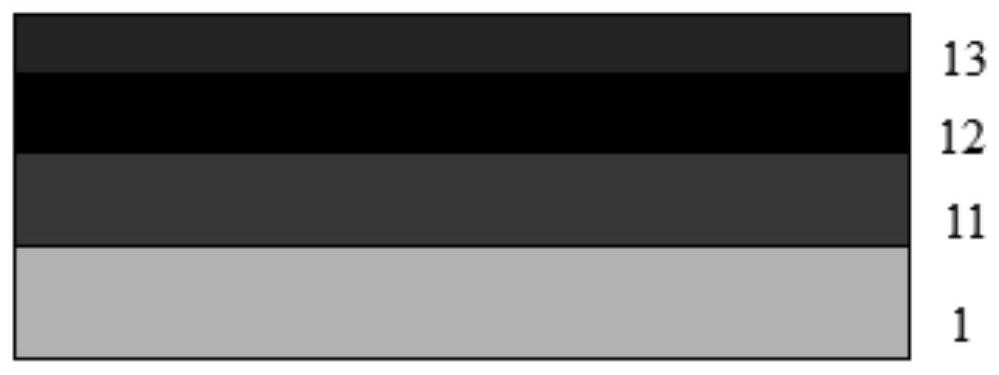

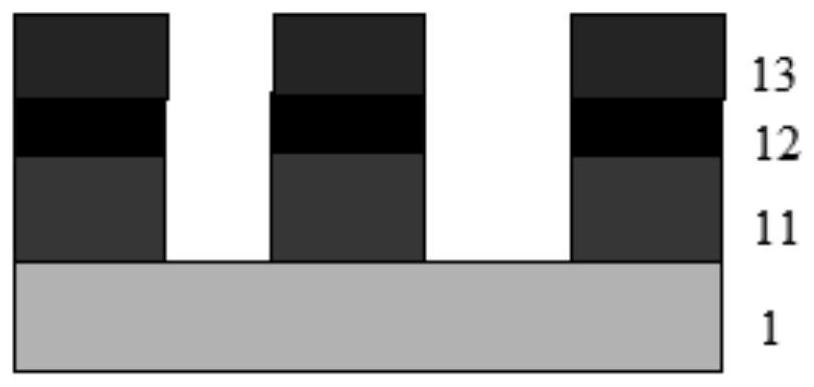

[0047] b) sequentially forming a phase-shift layer, a chromium nitride light-shielding film layer and a chromium oxynitride anti-reflection film layer on the treated glass substrate obtained in step a), to obtain an attenuation-type highly uniform phase-shift photomask blank;

[0048] The phase shift layer is a silicon oxide film.

[0049] In the invention, firstly, the glass substrate is pretreated to obtain the treated glass substrate. In the present invention, the glass substrate is the same as that described in the above technical solution, and will not be repeated here. It can be seen that, in the present invention, firstly, the glass substrate whose flatness and transmittance meet the conditio...

Embodiment 1

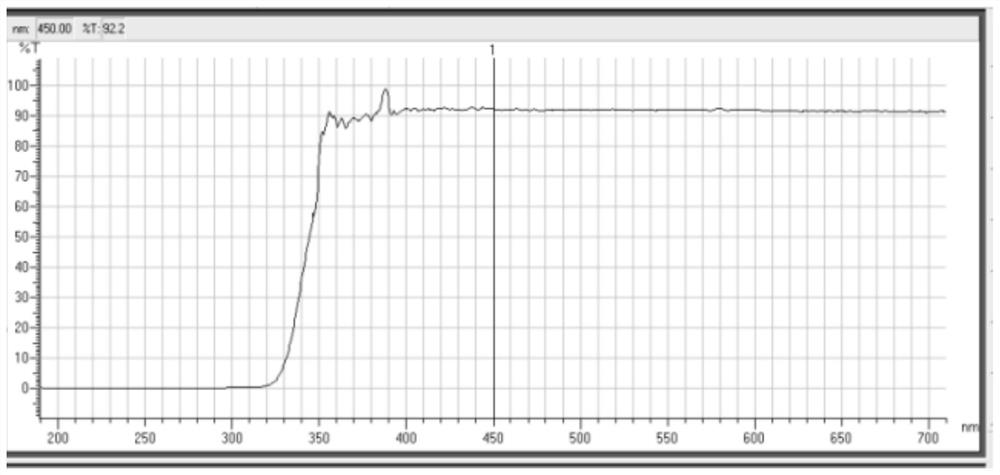

[0078] (1) Select flatness between 10nm and 12nm, transmittance (in the range of 400nm to 600nm, see figure 2 Shown) is 92% quartz glass for sample preparation; the quartz glass is soaked in electronic grade hydrofluoric acid (HF and pure water at a mass ratio of 1:20) at room temperature for 30 seconds and rinsed with warm pure water at 40°C for 10 minutes, and then rinsed with 60°C ℃ pure nitrogen drying to obtain the treated glass substrate.

[0079] (2) Provide a Si target material, and use the intermediate frequency magnetron sputtering method to plate a silicon oxide film on the treated glass substrate obtained in step (1) to form a phase shift layer; control the temperature of the glass substrate to 120 ° C, using The process gas is Ar, O 2 , whose ratio is in accordance with Ar:O 2 =3:20 volume ratio, the sputtering pressure is 0.13Pa.

[0080] (3) Test the uniformity and thickness distribution of the phase shift layer: use 64 vertical and horizontal points to meas...

Embodiment 2

[0093] (1) Select soda glass with a flatness of 15nm to 20nm and a transmittance (in the range of 400nm to 600nm) of 90% to prepare samples; pass the soda glass through normal temperature electronic grade hydrofluoric acid (HF and pure water according to mass ratio 1:20) soaked for 30s and rinsed with warm pure water at 40°C for 10min, and then dried with pure nitrogen at 60°C to obtain a treated glass substrate.

[0094] (2) Provide a Si target material, and use the intermediate frequency magnetron sputtering method to plate a silicon oxide film on the treated glass substrate obtained in step (1) to form a phase shift layer; control the temperature of the glass substrate to 120 ° C, using The process gas is Ar, O 2 , whose ratio is in accordance with Ar:O 2 =11:100 volume ratio, the sputtering pressure is 0.12Pa.

[0095] (3) Test the uniformity and thickness distribution of the phase shift layer: use 64 vertical and horizontal points to measure the size and uniformity of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com