Hydraulic dam with sand discharging structure

A hydraulic dam and hydraulic cylinder technology, applied in the field of water conservancy facilities construction, can solve the problems of poor impact resistance, not easy to rotate, short construction period, etc., achieve the effect of changing the overall height size, combining the structure cleverly, and improving the water storage depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in combination with specific embodiments.

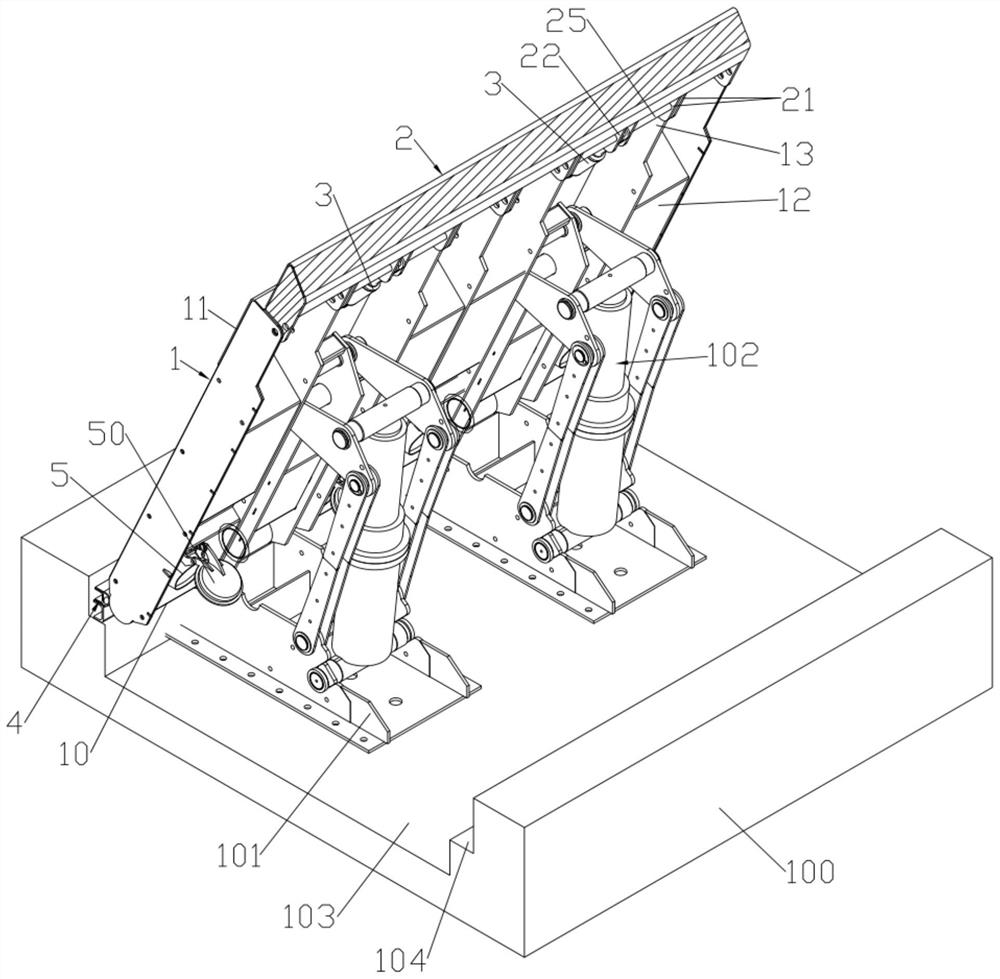

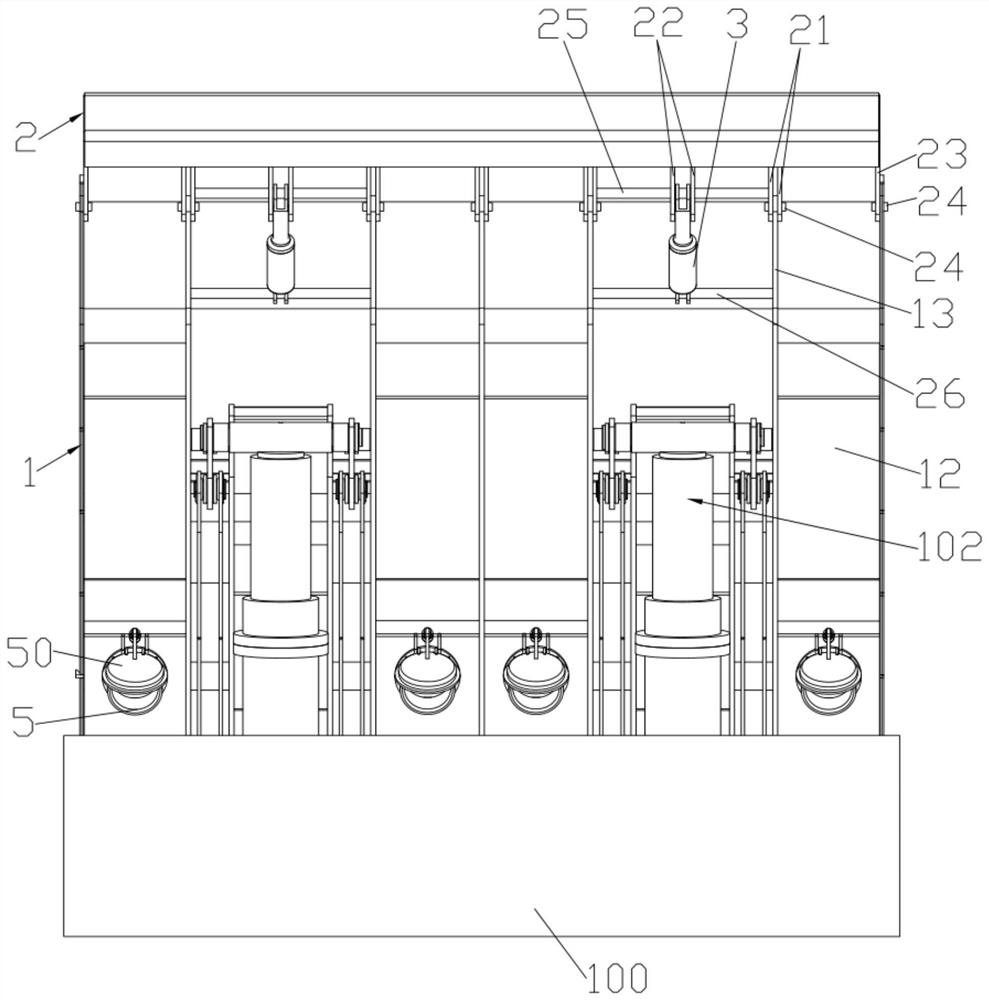

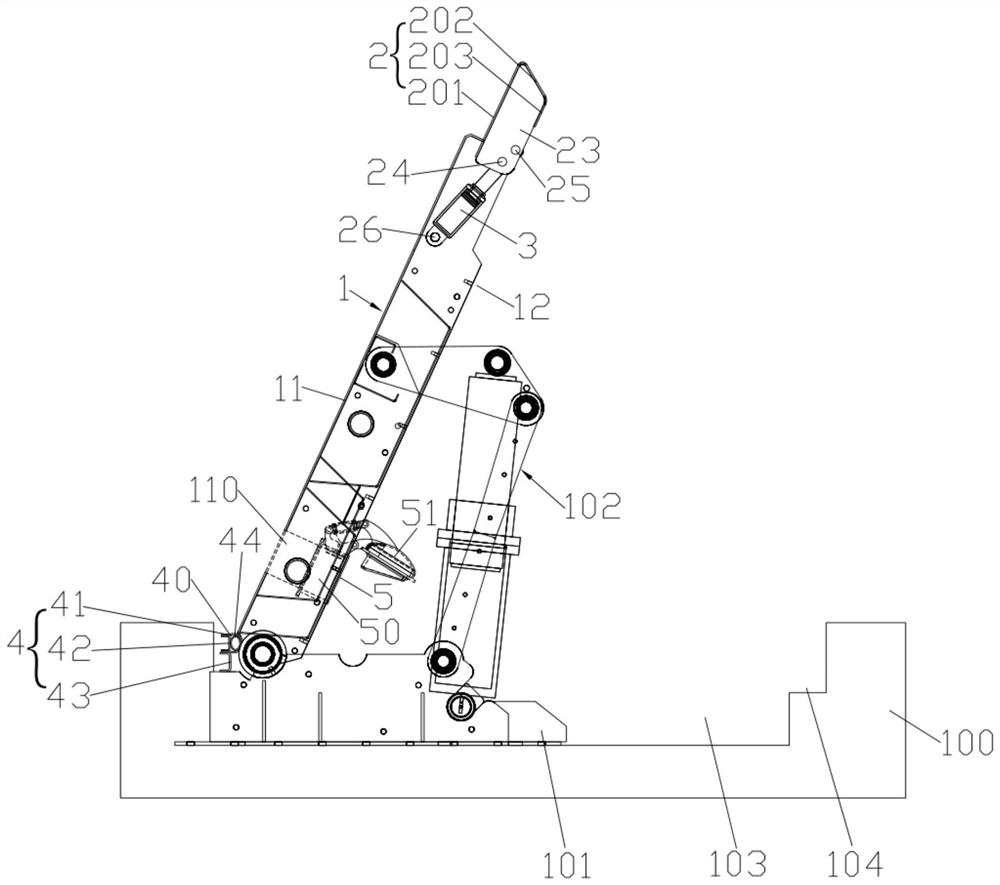

[0026] Such as Figures 1 to 4 As shown, the hydraulic dam with sand discharge structure according to one embodiment of the present invention includes a dam foundation 100 and a movable dam 1 . The dam foundation 100 is made of concrete. The dam foundation 100 is fixed with a base 101 through pre-embedding. A rotating shaft 10 is fixed at the bottom of the movable dam 1, and the rotating shaft 10 is rotatably connected to the base 101 . A hydraulic mechanism 102 is installed on the base 101 to be hinged with the rotating shaft 10 and the movable dam 1, so that the rotating shaft 10 drives the movable dam 1 to rotate. A water-stop assembly 4 is fixedly installed on the dam foundation 100 , and the water-stop assembly 4 is located on the side of the water-facing surface 11 of the movable dam 1 . The backwater surface 12 of the movable dam 1 is fixedly equipped with a sand d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com