Electrical equipment temperature sensor convenient to replace and monitoring method thereof

A temperature sensor, easy-to-replace technology, used in thermometers, thermometer applications, thermometer components, etc., can solve problems such as sensor replacement problems and equipment damage, and achieve the effect of flexible and changeable structure combinations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

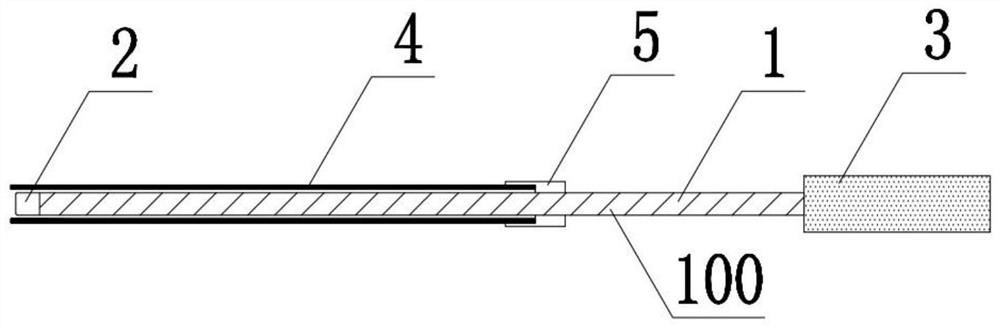

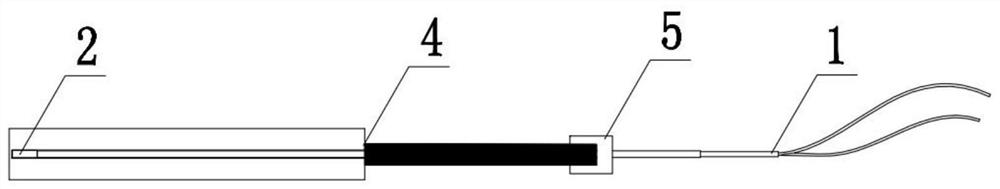

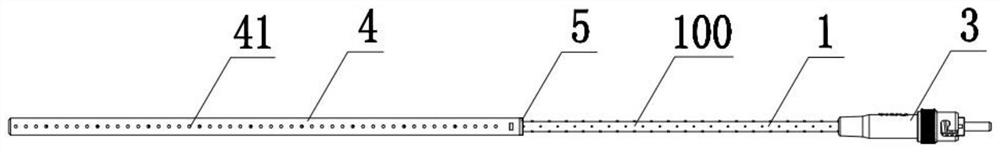

[0045] The inside and outside of the oil-immersed transformer winding assembly 200 is filled with insulating oil, and the voltage level is usually high. The direct hot spot measurement of the winding 201 can only use the optical fiber temperature sensor. In order to ensure the insulation effect and electrical performance, this case uses PTFE tube as The guide pipe 4, and the opening 41 is set on the pipe wall to ensure the good fluidity of the insulating oil, the structure is as follows image 3 shown;

[0046] Before use, remove the guide tube 4 and the fastener 5 and place them separately (the integral guide tube and the fastener can loosen the fastener), such as Figure 4 As shown, one end of the guide pipe 4 is closed, and the other end is an opening provided with a fastener 5 fixing window;

[0047] Then, according to the temperature measurement requirements, the guide pipe 4 is arranged at the position to be tested of the winding 201 during the production of the winding...

Embodiment 2

[0049] Use of fixed sensors in generator stator and rotor 300 Figure 8 Structure, the fastener 5 is composed of a pin 51 and a gland 52, the material of the guide tube 4 is epoxy resin fiberboard, and the guide groove is processed on the board, the cross section of the groove can be circular or rectangular, and the radial direction can be straight or curved. There is a direction hole on the top to fit the gland 52. Two pins 51 are used between the gland 52 and the guide tube 4 to fix the temperature sensor 100 on the guide groove. The bottom of the gland 52 has pressing teeth consistent with the width of the wire 1. The groove-shaped fixing structure has a penetrating hole on both sides. The diameter of the penetrating hole is smaller than the size of the pin 51. The pin 51 will not fall off after being pressed in. Connection method;

[0050] Such as Figure 9 , Figure 10 As shown, remove the guide groove and fixing structure before using the sensor; Figure 12 As shown,...

Embodiment 3

[0052] Such as Figure 14 , Figure 15 As shown, when the sensor needs to penetrate a long length, the penetration part of the front end of the sensor can be designed as an interventional tube type. Taking the optical fiber temperature sensor as an example, the main body of the sensor includes: connector 3, wire 1, tail sleeve 6, intervention Tube fastener 7, intervention tube 8 and temperature probe 2, a tail sleeve 6 and an intervention tube fastener 7 are added to the front end of the wire 1, and an intervention tube 8 is added to the front end of the intervention tube fastener 7. The material of the intervention tube 8 can be PTFE, PEEK, epoxy resin tubes, etc., the top of the intervention tube 8 is the temperature probe 2, the function of the intervention tube 8 is the same as that of the wire 1, and the guide tube 4 that is matched with the main body of the sensor is designed according to the different scenarios during use;

[0053] In order to prevent deformation of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com